Thermal dye sublimation ribbon for printing reflective mark, preparation method and reflective mark

A thermal sublimation, marking technology, applied in printing, ink ribbon, illuminated markings, etc., can solve the problems of unable to print true color, unable to apply logo scenes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

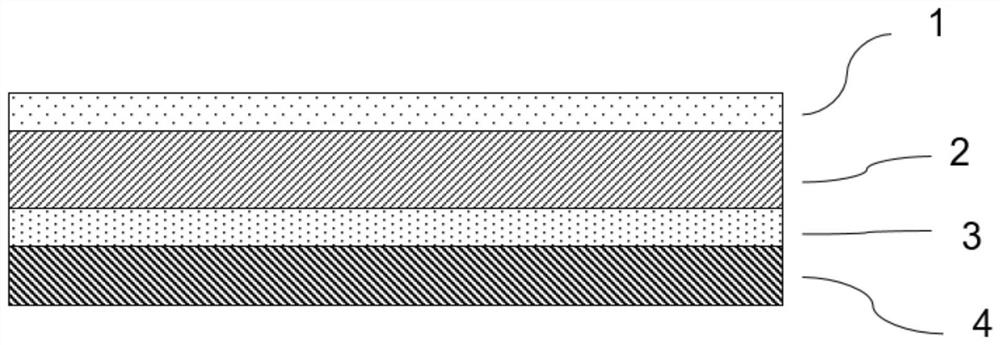

[0041] The preparation method of the thermal lifting carbon strip of the present invention includes the following steps:

[0042] 1) Preparation of each coating solution;

[0043] Among them, the preparation method of the back coating 1 is, the polyamide imine resin is dissolved with 2-butanone and toluene, and then zinc stearate and silica particles are added, and the silica particles are dispersed in the solution. The leveling agent, dispersant, antistatic agent is mixed, and the solution of the backcoating layer 1 is obtained.

[0044] The solution preparation method of the undercoat layer 3 is, dissolved the petroleum resin, EVA resin, dissolved with 2-butanone and toluene and mixed, and mixed, resulting in a solution of the bottom coating 3.

[0045]The solution formulation method of the dye layer 4 is to dissolve the petroleum resin, EVA resin, and dissolve 2-butanone and toluene, then add 1.0-10% by weight of the mono-colored mono-colored single dye or multi-dye mixture, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com