Beam column joint template

A beam-column joint and beam formwork technology, which is applied to formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problem that the gap of the joint is not easy to be controlled within the allowable range of the specification, and the formwork is prone to displacement. , uneven concrete surface and other problems, to ensure safe use function and visual quality, reduce the necking of the column section, and reduce the phenomenon of mold expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described below with reference to the accompanying drawings. Those skilled in the art would recognize that the described embodiments can be modified in various ways or combinations thereof without departing from the spirit and scope of the invention. Accordingly, the drawings and description are illustrative in nature and not intended to limit the scope of the claims. Also, in this specification, the drawings are not drawn to scale, and like reference numerals denote like parts.

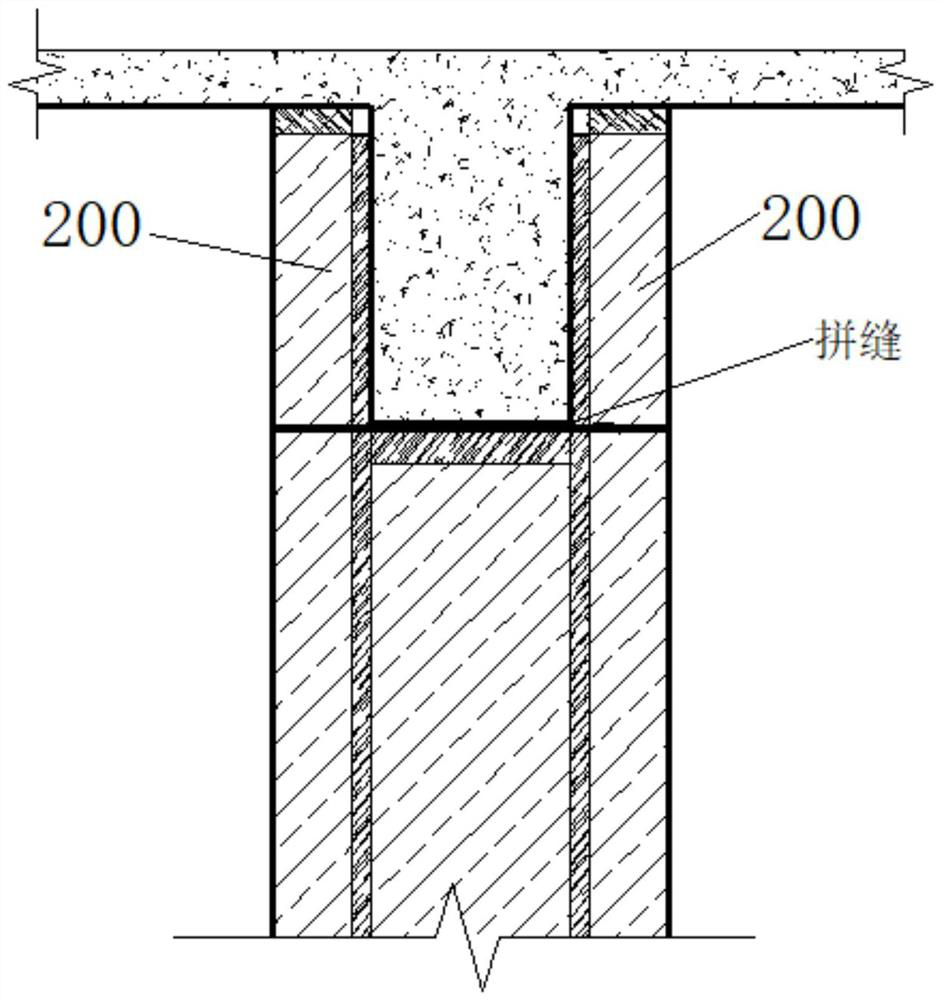

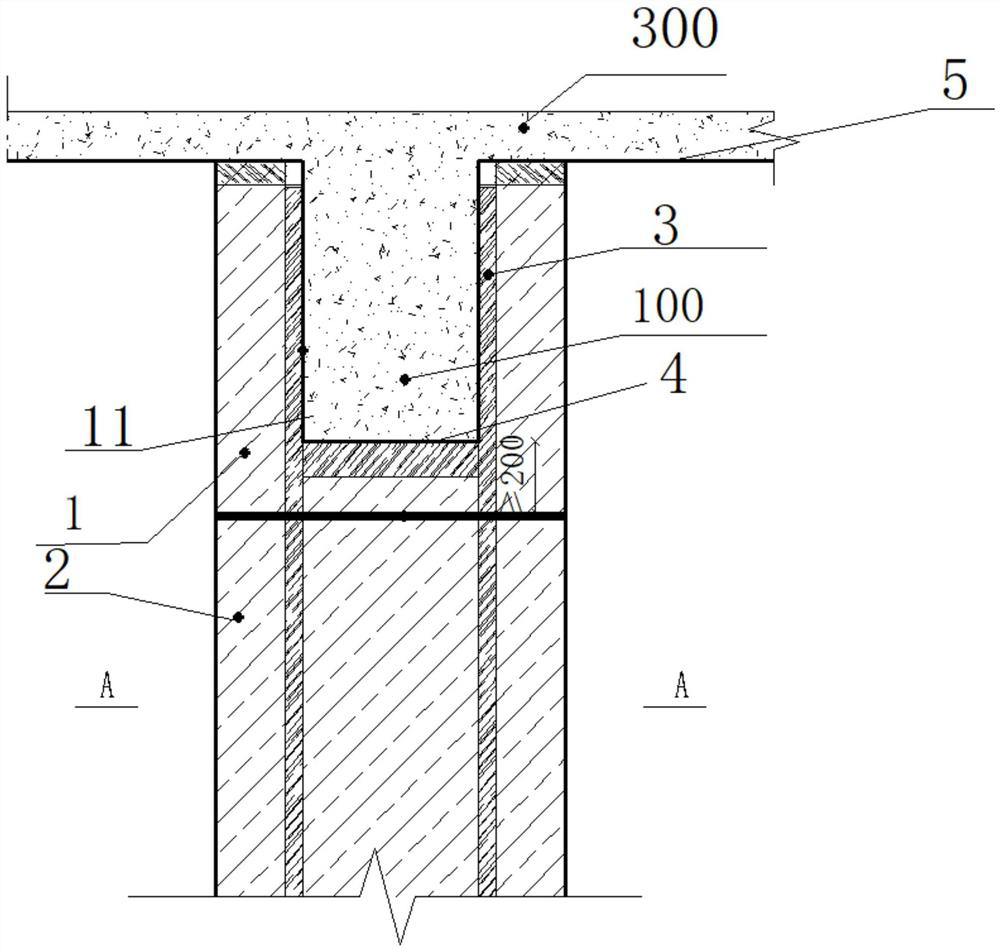

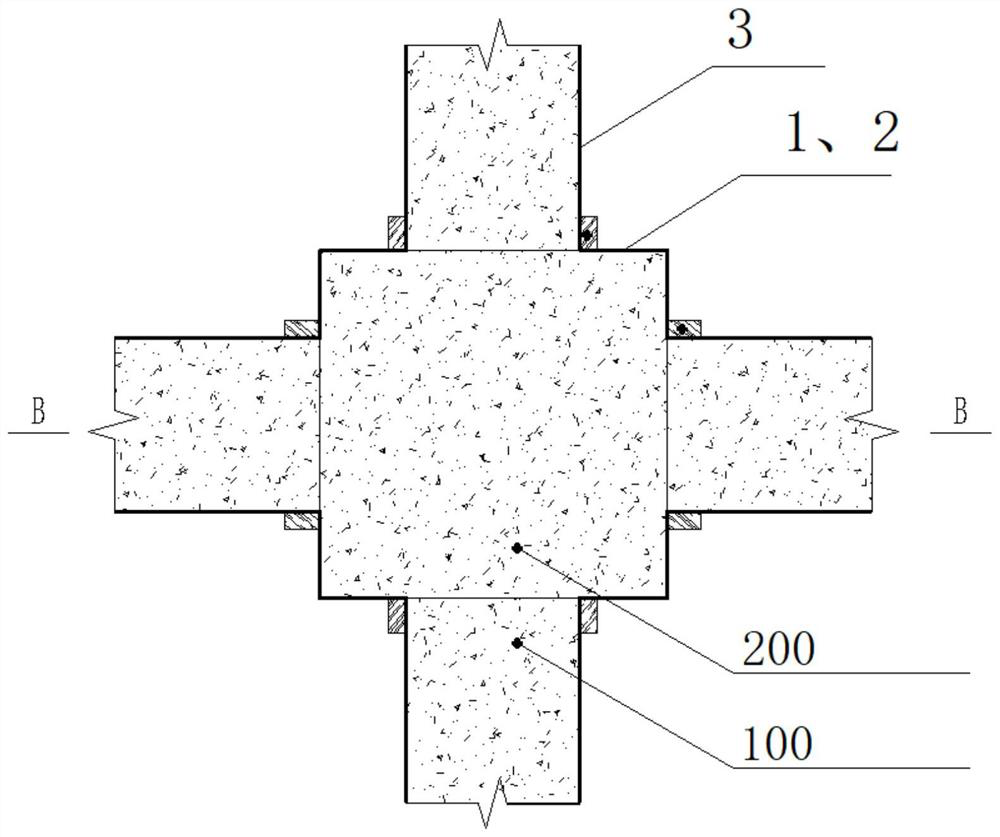

[0028] The beam-column joint formwork of this embodiment includes a column side formwork and a beam formwork, such as figure 2 As shown, each column side formwork includes an upper column side formwork 1 and a lower column side formwork 2, and the formwork encloses the pouring space for beams and columns. Among them, the upper column side formwork 1 and the lower column side formwork 2 are formworks on the same column side along the cross-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com