Double triple fluted disc reliability test device and method based on all-condition simulation

A triple chainring and test device technology, which is applied to measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problem of a single test object, and achieve improved detection efficiency, high equipment utilization, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

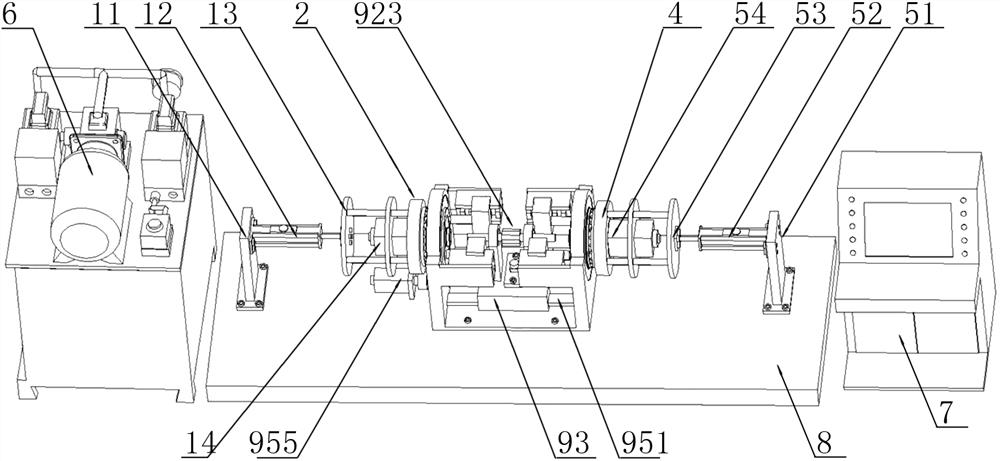

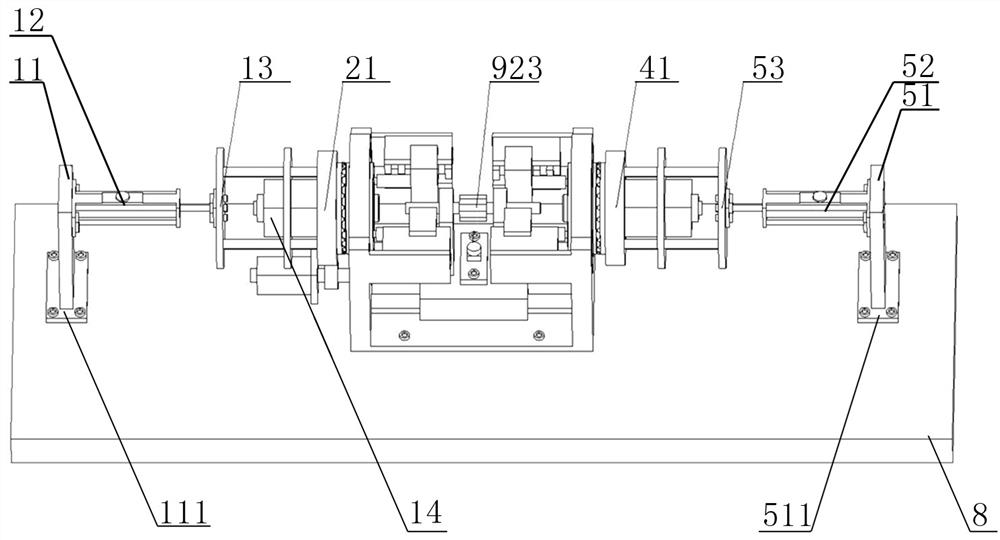

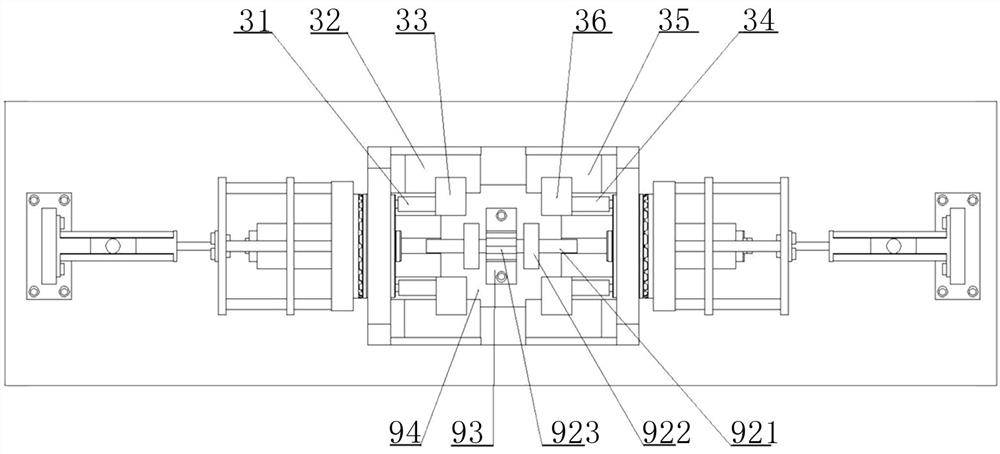

[0091] Embodiment 1 A kind of reliability test device for double triple chainrings simulated in full working conditions

[0092] see Figure 1 to Figure 4 As shown, a double triple chainring reliability test device for full working condition simulation, which includes: the first chainring running part, the first triple chainring 2, the loading part, the second triple chainring 4, the second Chainring operation department, hydraulic station 6, console 7, horizon iron 8, detection unit 9;

[0093] The first triple tooth disc 2 is fixed on the first tooth disc running part; the second triple tooth disc 4 is fixed on the second tooth disc running part; the first triple tooth disc 2, the loading part, the second triple tooth The plates 4 are connected sequentially; the loading part is fixed on the horizontal iron 8 through the detection unit 9; the hydraulic station 6 and the console 7 are arranged on both sides of the horizontal iron 8;

[0094] The hydraulic station 6 provides ...

Embodiment 2

[0135] Embodiment 2 A kind of reliability test method of double and triple chainrings simulated in full working conditions

[0136] see Figure 5 to Figure 7 As shown in Fig. 1 , a reliability test method for double triple chainrings simulated under full working conditions includes the following steps: preparatory work before the test, opening the equipment, adjusting the test bench to the working position, testing the accuracy of the triple chainrings before the test, and loading the triple chainrings. , After the test, check the accuracy of the triple toothed disc, adjust the test bench to the non-working position, analyze the data, and shut down the equipment;

[0137] (1) Preparation before the test

[0138] 1) Before the test, check the lubrication and cooling conditions of the test system;

[0139] 2) Detect whether there is looseness of each connecting piece;

[0140] 3) Detect whether the hydraulic pressure of the hydraulic station is in the normal working position;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com