Flow battery stack structure

A technology for flow batteries and battery electrodes, which is applied to fuel cells, regenerative fuel cells, and components of fuel cells, etc., can solve problems such as excessive flow resistance, unfavorable electrolyte flow, and decreased system efficiency, and achieve improved flow power. , the effect of increasing the electrochemical reaction rate and increasing the pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

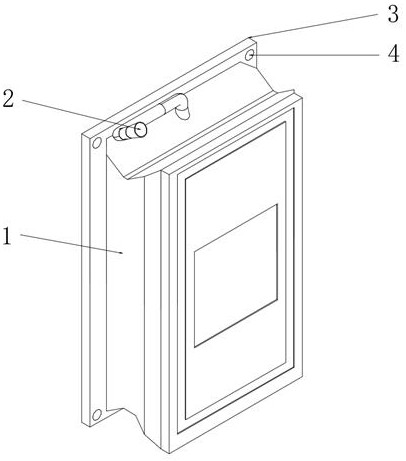

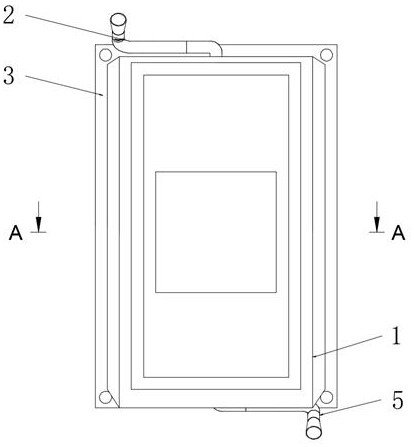

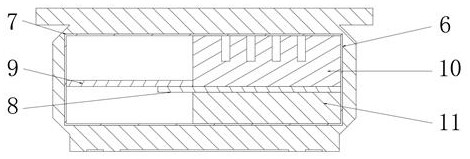

[0031] Such as figure 1 , 2 , 3, 4, 5, 6, and 7, the embodiment of the present invention provides a flow battery stack structure, including a battery electrode frame 1, and an installation cavity 6 is opened inside the battery electrode frame 1, The upper end of the battery electrode frame 1 is fixedly equipped with an electrolyte outlet flow channel 2, one end of the electrolyte outlet flow channel 2 communicates with the interior of the installation cavity 6, and the other end of the electrolyte outlet flow channel 2 is connected to the The electrolyte storage tank is connected, and the end of the battery electrode frame 1 away from the electrolyte outlet flow channel 2 is installed with an electrolyte inlet flow channel 5, and the electrolyte inlet flow channel 5 includes a connecting pipe 501, a feed port joint 502 and installation pipe 503, the connecting pipe 501 includes a connecting pipe main body 501a, one end of the connecting pipe main body 501a is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com