Bean sprout harvester

A technology for harvesters and bean sprouts, which is applied to harvesters, agricultural machinery and tools, and agricultural gas emission reduction. It can solve the problems of difficult recycling of culture trays, easy deviation of cutting parts, and troublesome harvesting methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

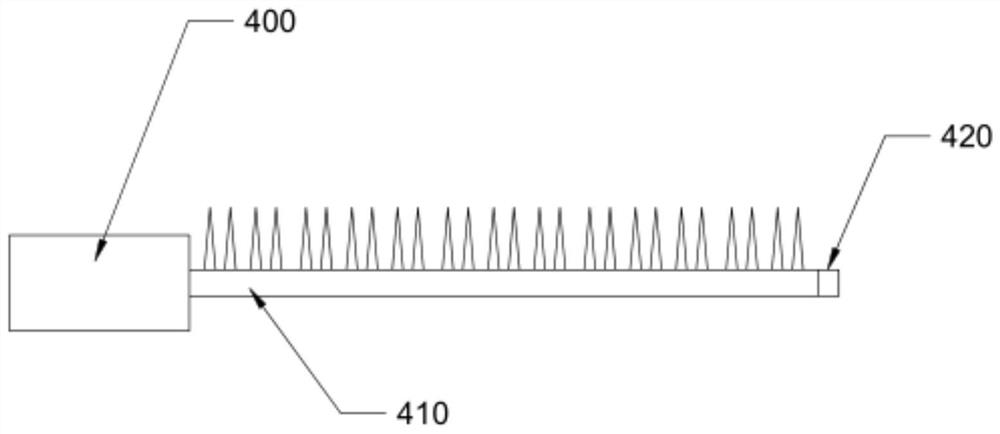

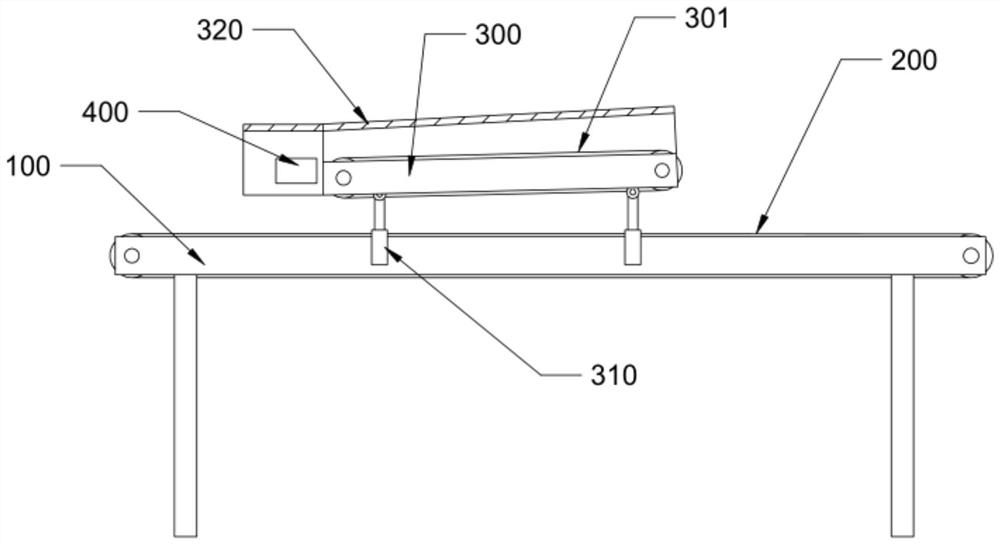

[0028] like Figure 2-4 As shown, the present embodiment provides a bean sprouts harvester, including a first conveyor belt 200, a cutting assembly, a separation frame 300 and a frame 100: the first conveyor belt 200 is installed on the frame 100; the cutting assembly is set On the separating frame 300, the cutting assembly includes a cutting power part 400, a moving knife set 410 and a fixed knife set 420, the moving knife set 410 and the fixed knife set 420 are stacked, and the fixed knife set 420 and the fixed knife set 420 The separating frame 300 is fixedly connected, and the cutting power part 400 is fixedly connected with the separating frame 300 and drives the moving knife set 410 to reciprocate; the moving knife set 410 and the fixed knife set 420 both include a strip-shaped base body and A plurality of blades arranged on the substrate, the blades of the movable knife group 410 and the blades of the fixed knife group 420 are opposite to each other, and the cutting pow...

Embodiment 2

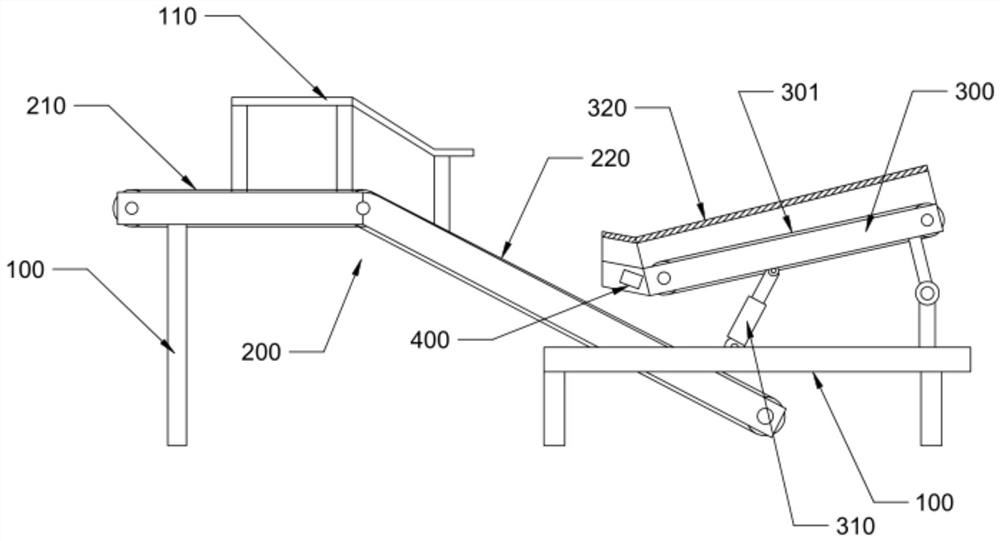

[0036] like figure 1 As mentioned above, the main structure and inventive concept of this embodiment are the same as that of Embodiment 1, and the adjustment method of the separation frame 300 is mainly improved. Specifically, the first conveyor belt 200 preferably includes a horizontal section 210 and an inclined section 220, and the inclined Segment 220 joins said horizontal segment 210 and extends downward.

[0037] Wherein, the separation frame 300 is located above the inclined section 220, the first end of the separation frame 300 is hinged with the frame 100, and the second end of the separation frame 300 is hinged with the gap adjusting member 310 . The cooperation between the separation frame 300 and the inclined section 220 makes the separation frame 300 have a larger adjustment space. The adjustment of the separation frame 300 can be realized only by disposing the gap adjusting member 310 at the second end of the separation frame 300 . The cutting assembly is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com