An intelligent textile palletizing and conveying system

A conveying system and palletizing technology, which is applied in the field of intelligent textile palletizing conveying system, can solve the problems of low space utilization, complex structure, high equipment cost, etc., and achieve the goal of realizing spatial distribution, saving workshop space and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

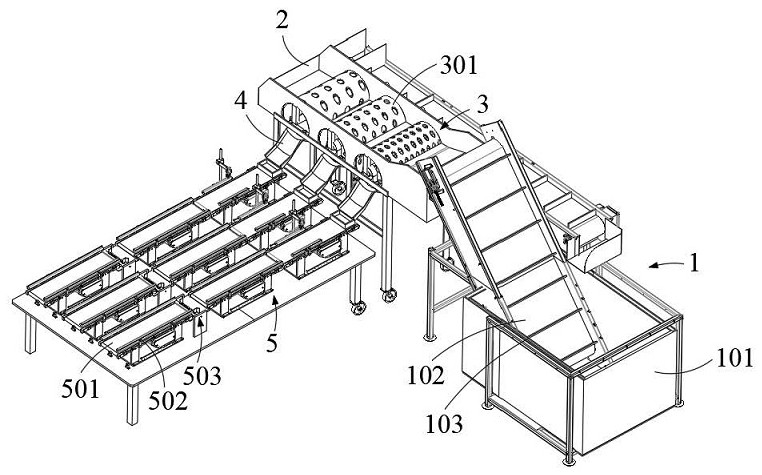

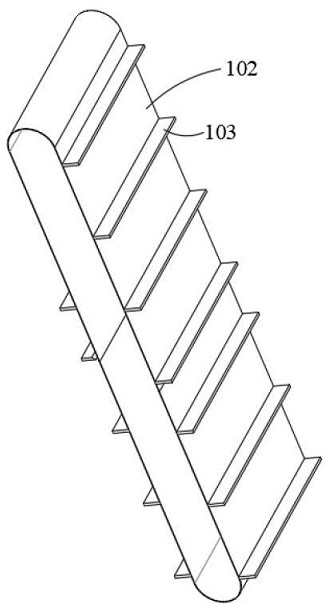

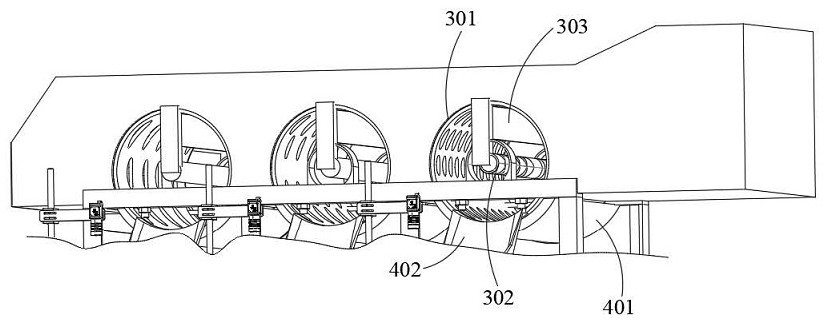

[0040] In this embodiment, as Figure 1 to Figure 6 As shown, this embodiment provides an intelligent textile palletizing and conveying system, which includes: a feeding and conveying device 1, a screening bin 2, at least two screening mechanisms 3, at least two guide plates 4 and at least two The feeding conveying device 5; wherein the feeding conveying device 1 and the feeding conveying device 5 are located below the screen bin 2, and each of the screening mechanisms 3 is arranged in parallel in the screen bin 2, and each of the screening mechanisms The output port of 3 is connected to the corresponding unloading conveying device 5 through the corresponding guide plate 4; the material feeding and conveying device 1 receives the material and conveys the material to the screening bin 2; the screening mechanisms 3 are respectively Screen the materials in the screening bin 2, that is, each of the screening mechanisms 3 respectively screen out the materials of the corresponding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com