Straightening and crack arresting method for eliminating edge cracks during rolling of ultra-thin strip

A technology of edge cracks and ultra-thin strips, applied in metal rolling, contour control, etc., to achieve the effects of improving economic benefits, eliminating edge cracks, and strong driving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

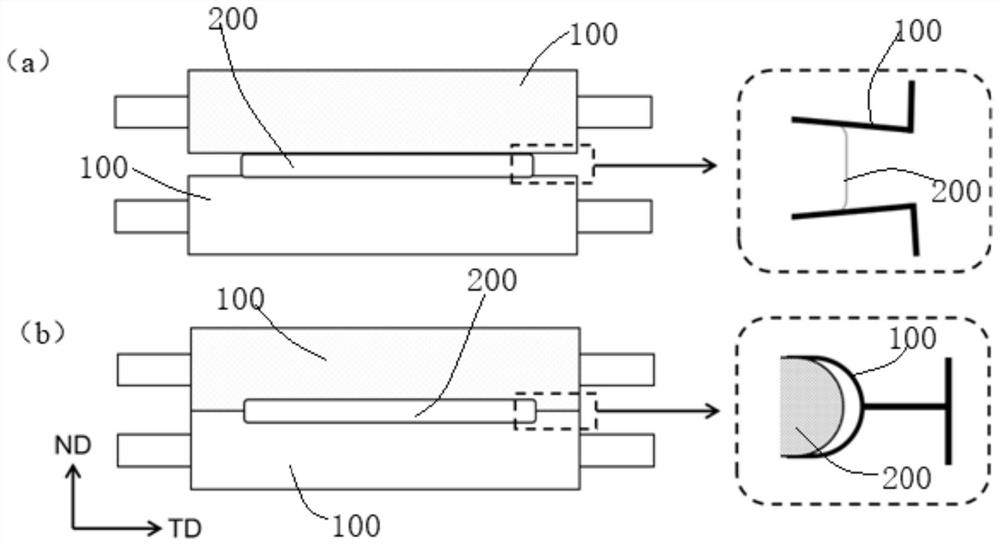

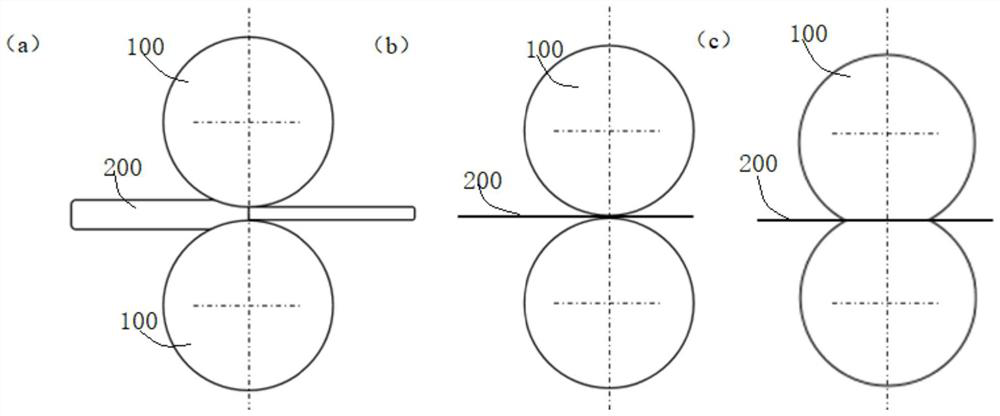

[0035] Such as Figure 1-Figure 5 As shown, a kind of straightening and arresting method for eliminating edge cracks when rolling an ultra-thin strip in this embodiment includes:

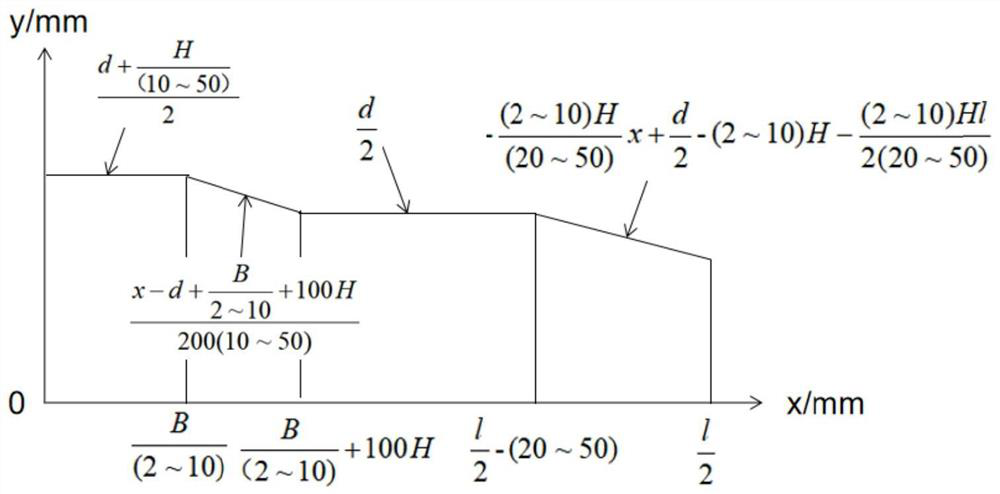

[0036] S1. Rough rolling with large reduction: select industrial pure titanium with a thickness of 8mm and a width of 120mm. After 12 passes of cold rolling, the thickness of the rolled piece 200 is reduced to 0.15mm. During the rolling process, the lower roll used is 100mm The degree is 2 μm, and the crown of the upper roll 100 is 50 μm.

[0037] S2. Shape adjustment rolling with small reduction: After the strip threading is completed, a pre-compression force of 100kN is applied, and the initial tension is 15% of the yield stress of the metal material with the same thickness. The used roll 100 has a diameter of 90 mm and a roll surface width of 200 mm. After 2 passes of small reduction rolling, the reduction of each pass is 10%, and the metal plate is strip-rolled to a thickness of 0.08 mm.

[00...

Embodiment 2

[0042] A kind of straightening and arresting method for eliminating edge cracks when rolling an ultra-thin strip in this embodiment is basically the same as in Embodiment 1. More specifically, the oxygen-free copper metal with a thickness of 10 mm and a width of 140 mm is used in this embodiment. materials, the process is as follows:

[0043] S1. Rough rolling with large reduction: After 15 passes of cold rolling, the thickness of the rolled piece 200 is reduced to 0.12 mm. During the rolling process, the lower roll 100 used has a crown of 1 μm, and the upper roll 100 has a crown of 1 μm. 70 μm.

[0044] S2. Shape adjustment rolling with small reduction: After the strip threading is completed, a pre-compression force of 200kN is applied, and the initial tension is 20% of the yield stress of the metal material with the same thickness. The used roll 100 has a diameter of 300 mm and a roll surface width of 600 mm. After 4 passes of small reduction rolling, the reduction of each ...

Embodiment 3

[0047] A kind of straightening and arresting method for eliminating edge cracks when rolling an ultra-thin strip in this embodiment is basically the same as in Embodiment 1. More specifically, in this embodiment, a nickel or magnesium alloy with a thickness of 1mm and a width of 50mm is selected. The material is rolling piece 200, the process is as follows:

[0048] S1. Rough rolling with large reduction: After 5 passes of cold rolling, the thickness of the rolled piece 200 is reduced to 0.1 mm. During the rolling process, the lower roll 100 used has a crown of 0 μm, and the upper roll 100 has a crown of 0 μm. 40 μm.

[0049] S2. Shape adjustment rolling with small reduction: After the strip threading is completed, apply a pre-compression force of 50kN, and the initial tension is 10% of the yield stress of the metal material with the same thickness. The used roll 100 has a diameter of 120 mm and a roll surface width of 300 mm. After one pass of small reduction rolling, the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Convexity | aaaaa | aaaaa |

| Convexity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com