Silicone rubber cutting device and cutting method

A cutting device, silicone rubber technology, applied in the direction of metal processing, etc., to achieve the effect of reducing silicone rubber debris, increasing cutting speed, and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

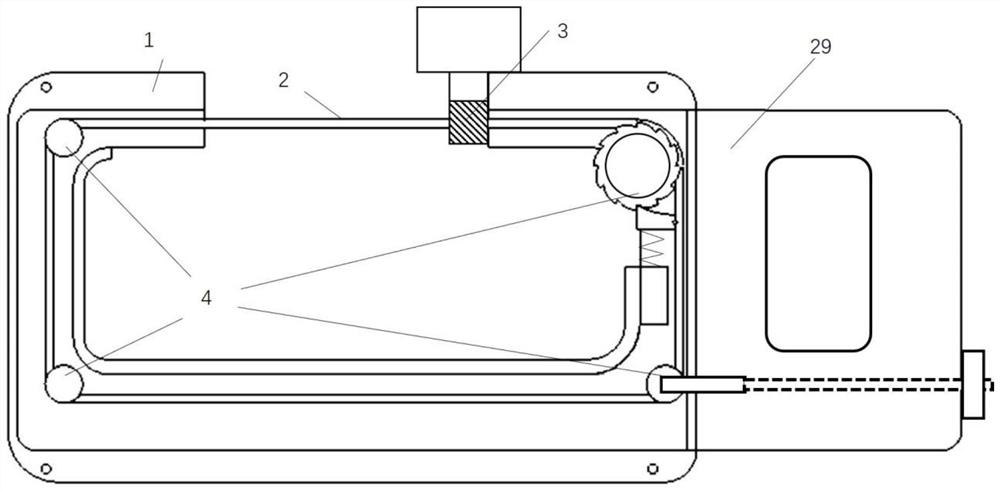

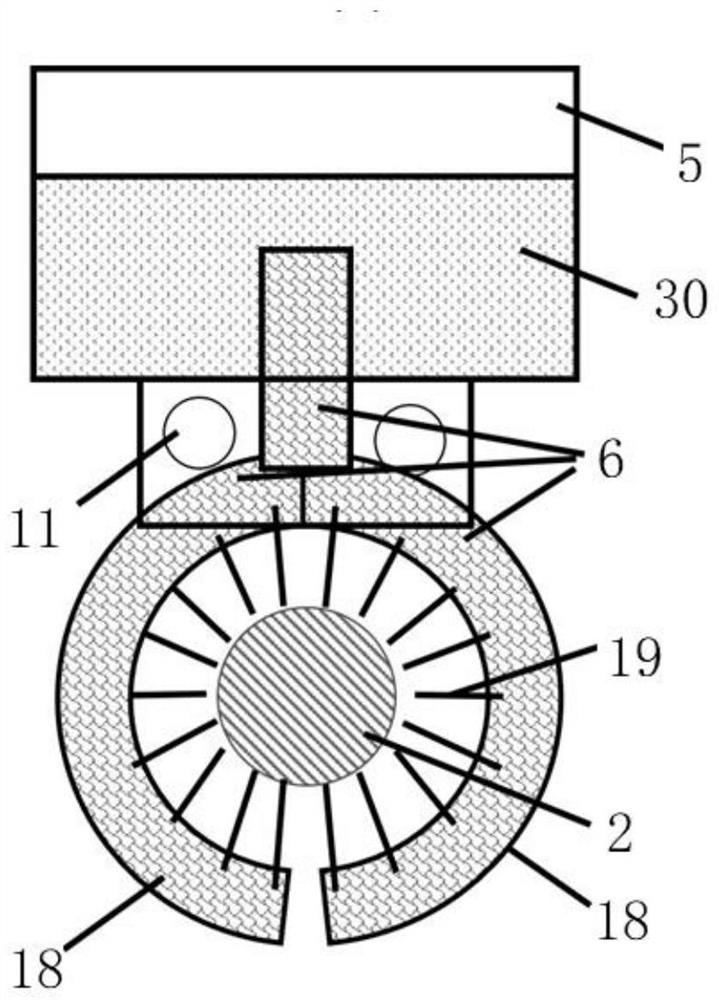

[0052] Such as figure 1 As shown, a silicone rubber cutting device includes a cutting body, a steel wire, a detachable brush head, and a supporting circulation assembly.

[0053] The cutting body includes a U-shaped frame and a cover plate detachably mounted on the U-shaped frame; a hollow cavity is formed between the U-shaped frame and the cover plate; the cover plate can be installed on the side of the frame by screws; There is also a handle.

[0054] The steel wire is installed in the cutting body through the supporting circulation assembly, wherein the steel wire exposed at the U-shaped opening can be directly used to cut the silicone rubber.

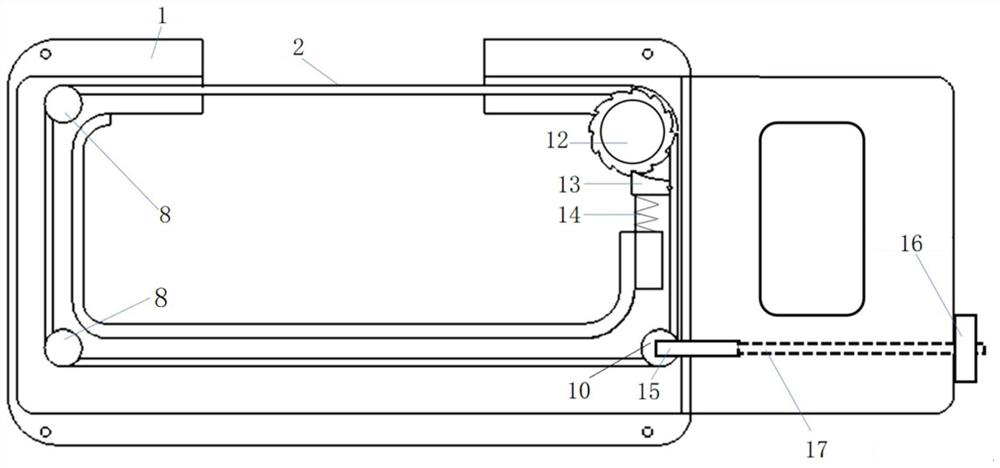

[0055] Such as figure 2 As shown, the detachable brush head is installed by screws on the port where the steel wire enters the cutting body at the U-shaped opening, which includes a liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com