Vacuum grain storage barrel capable of automatically sensing air exhaust and control method

An automatic sensing and vacuuming device technology, which is applied in packaging under vacuum/special atmosphere, capping with auxiliary devices, sealing parts with auxiliary devices, etc., can solve the problems of cumbersome operation, high energy consumption, and low degree of automation , to achieve the effect of convenient operation, low power consumption, and overall aesthetic improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings. Among them, the orientation nouns such as "up" and "down" mentioned in this article are preceded by figure 1 orientation as a reference.

[0088] Although exemplary embodiments of the present invention are shown in the drawings, it should be understood that the invention may be embodied in various forms and should not be limited to the embodiments set forth herein. Rather, these embodiments are provided so that the present invention can be more clearly and thoroughly understood, and the scope of the present invention can be fully conveyed to those skilled in the art.

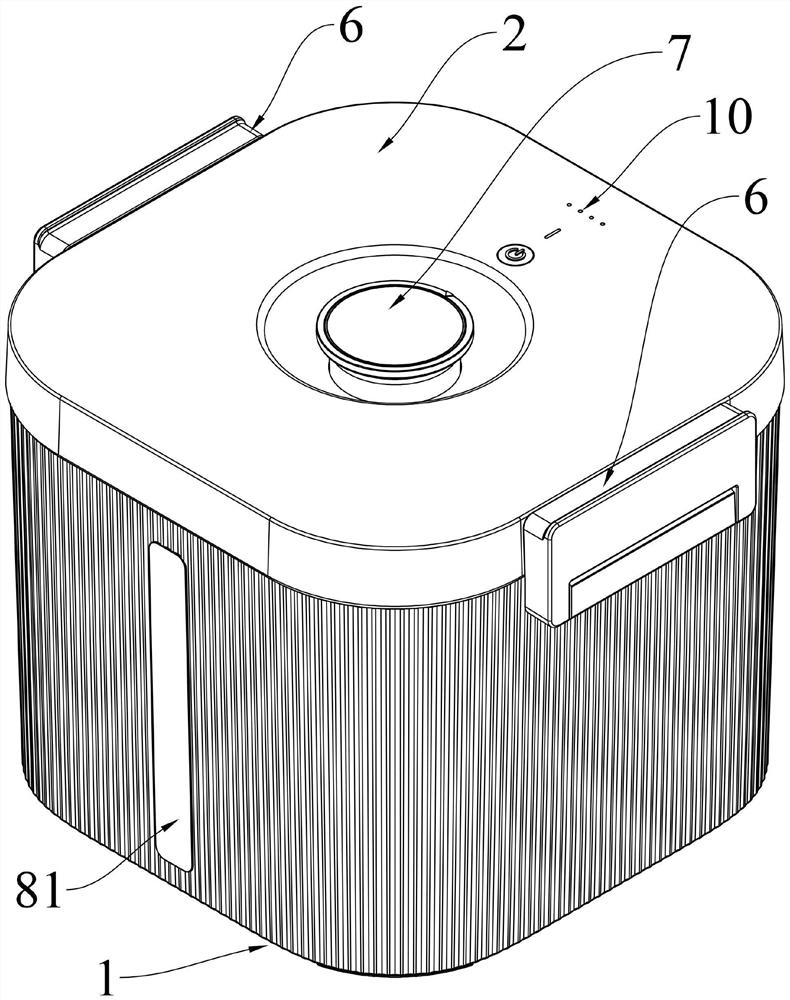

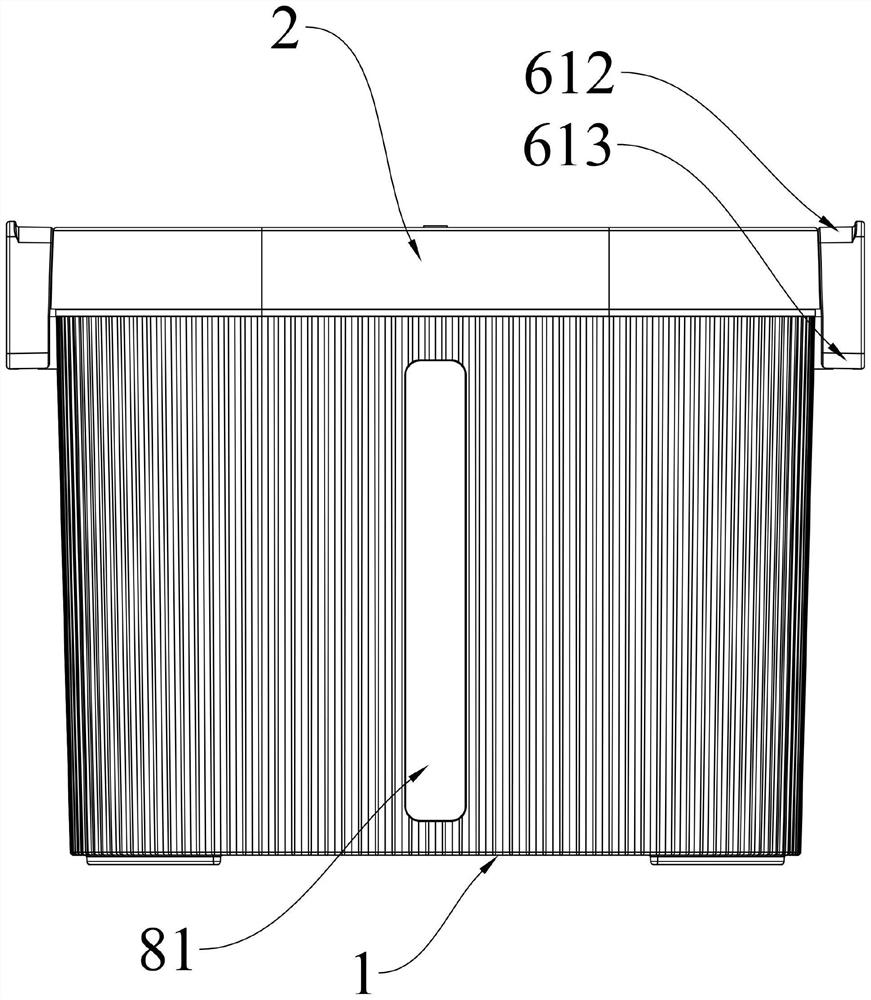

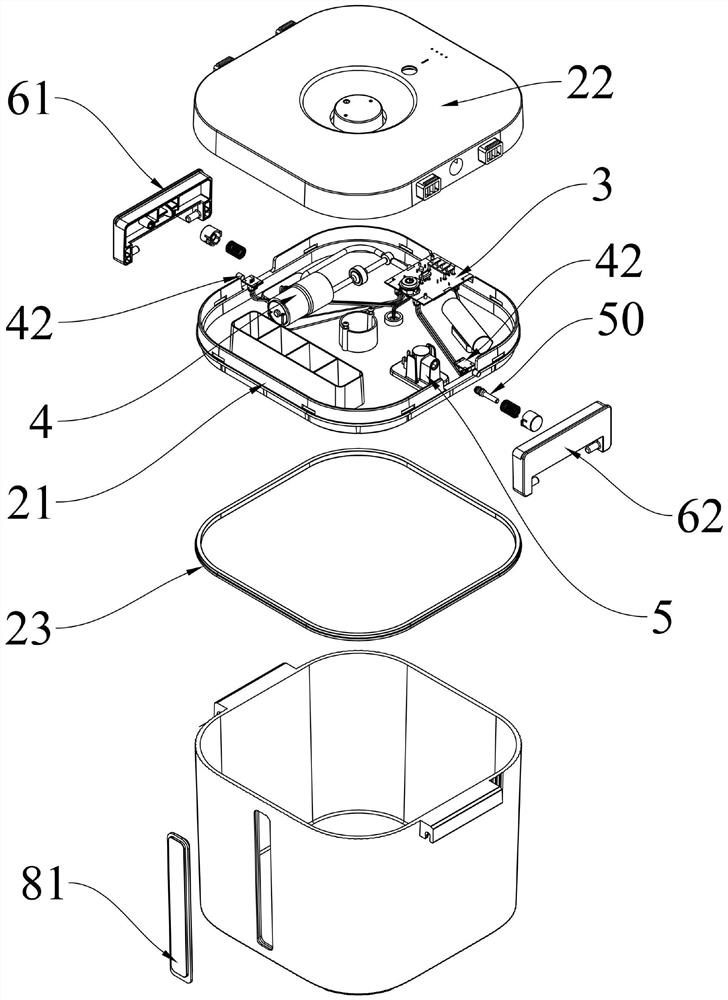

[0089] Such as Figure 1 to Figure 3 As shown, the present invention provides a vacuum grain storage barrel with automatic induction pumping, which includes a barrel body 1 , a barrel cover 2 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com