Water-soluble unit dose articles comprising amine oxide surfactants and dominant non-aqueous solvents

A surfactant and non-aqueous solvent technology, applied in the field of water-soluble unit dose products, can solve the problems of affecting sealed products, limiting continuous filling speed, falling between cavities, etc., to achieve improved stability and less mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] Example 1: Liquid drawing

[0111] The following shear thinning liquid detergent formulations were prepared using standard mixing techniques and equipment known to those skilled in the art. In cases where the non-aqueous solvent was dominant (ie, the amount of non-aqueous solvent was greater than the amount of non-amine oxide surfactant), the amine oxide surfactant was added to the inventive samples. Comparative Samples 1 and 2 contained a non-aqueous solvent that was not dominant with the amine oxide surfactant (Comparative Sample 1) or without the amine oxide surfactant (Comparative Sample 2).

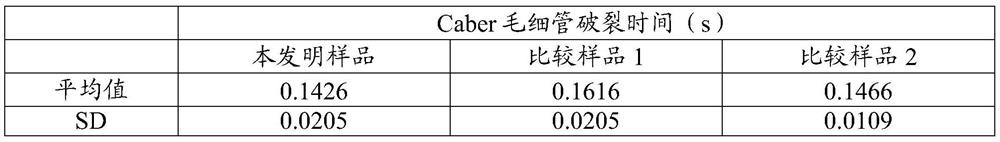

[0112] Table 1

[0113]

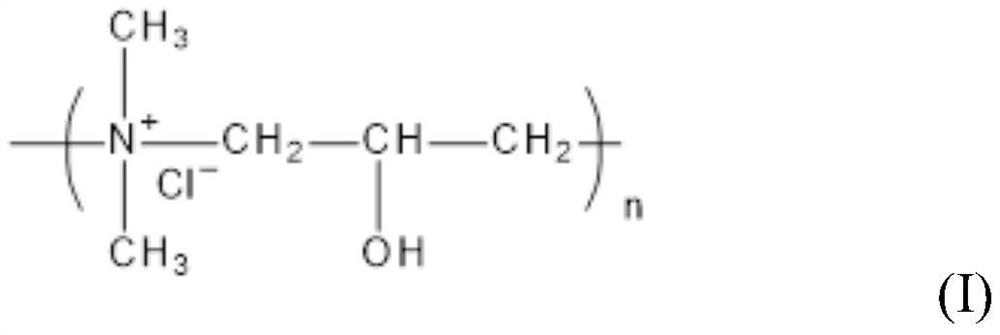

[0114] 1: Dye fixative: Poly(2-hydroxypropyldimethylammonium chloride), commercially available under the tradename TEXCARE DFC 6 from Clariant.

[0115] The liquid stringing distribution of these samples was evaluated by measuring the break time of capillaries formed when the test samples were stretched to a certain strain using a Haake Caber...

Embodiment 2

[0118] Example 2: Film plasticizing properties

[0119] The samples prepared as in Example 1 were evaluated for the effect of the addition of amine oxides on the plasticizing properties of water-soluble films in the presence of a predominantly non-aqueous solvent. A 75 μm thick polyvinyl alcohol-based water-soluble film (such as a blend of polyvinyl alcohol homopolymer and carboxylated anionic polyvinyl alcohol copolymer) as supplied by the company Monosol was used to evaluate the effect of film plasticization on laundry detergent combinations There is a dependence on amine oxide in the compound. Effect of Film Plasticization on the Presence of Amine Oxide in Laundry Detergent Formulations According to the Invention Water-soluble films were subjected to aging by measuring the film elastic properties (E-modulus) and by immersion in the formulations of inventive sample 1 and comparative samples 1 to 5 The stress at 100% strain after the experiment is defined. Immerse a 12cm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com