Railway tunnel ultrahigh pressure water cutting control execution mechanism and control system

An ultra-high pressure water cutting and actuator technology, which is applied in waterway systems, drainage, water supply devices, etc., can solve the problems of inability to discharge dirt, reduce the quality of dredging, time-consuming and laborious, and achieve the effect of improving quality and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

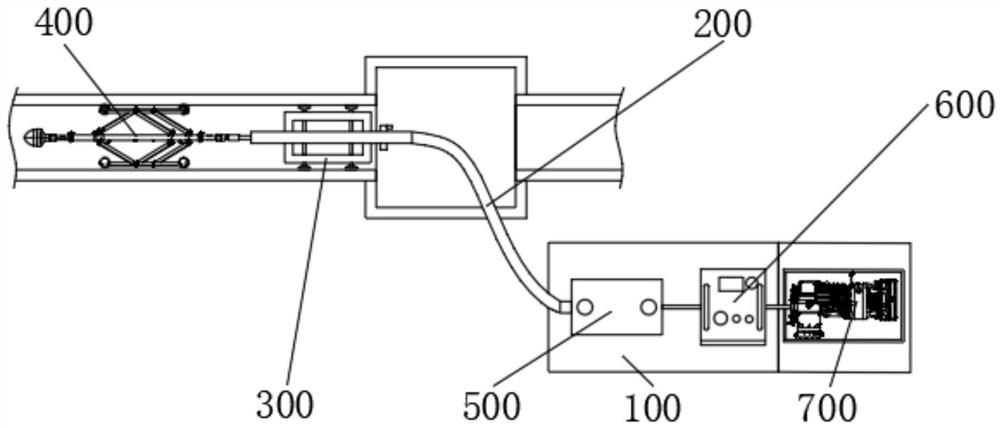

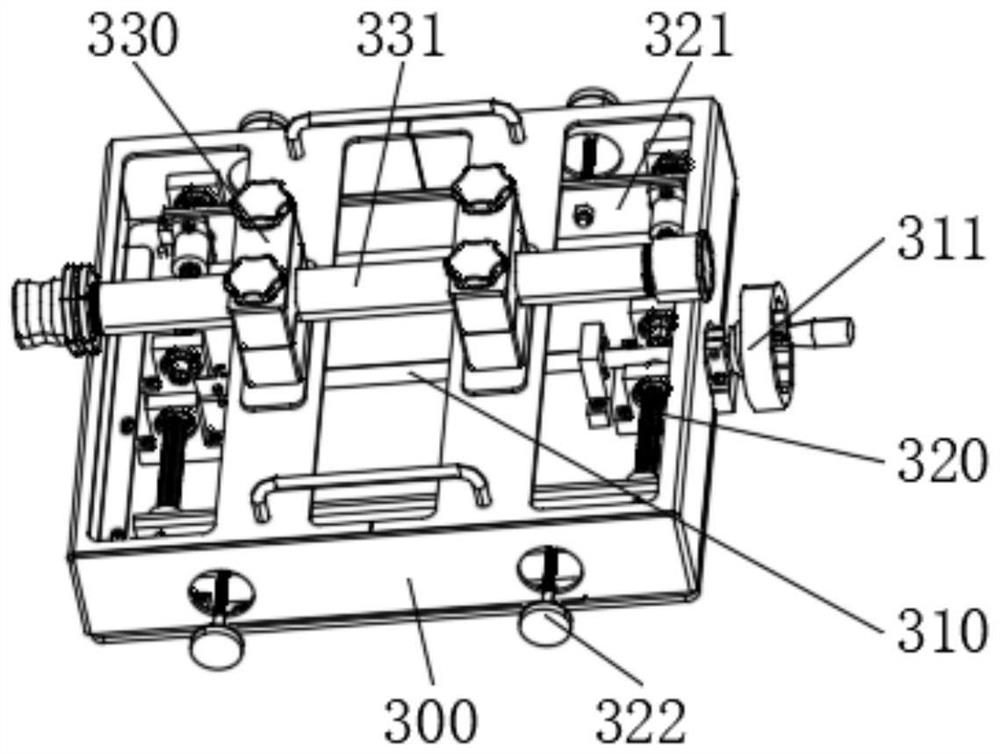

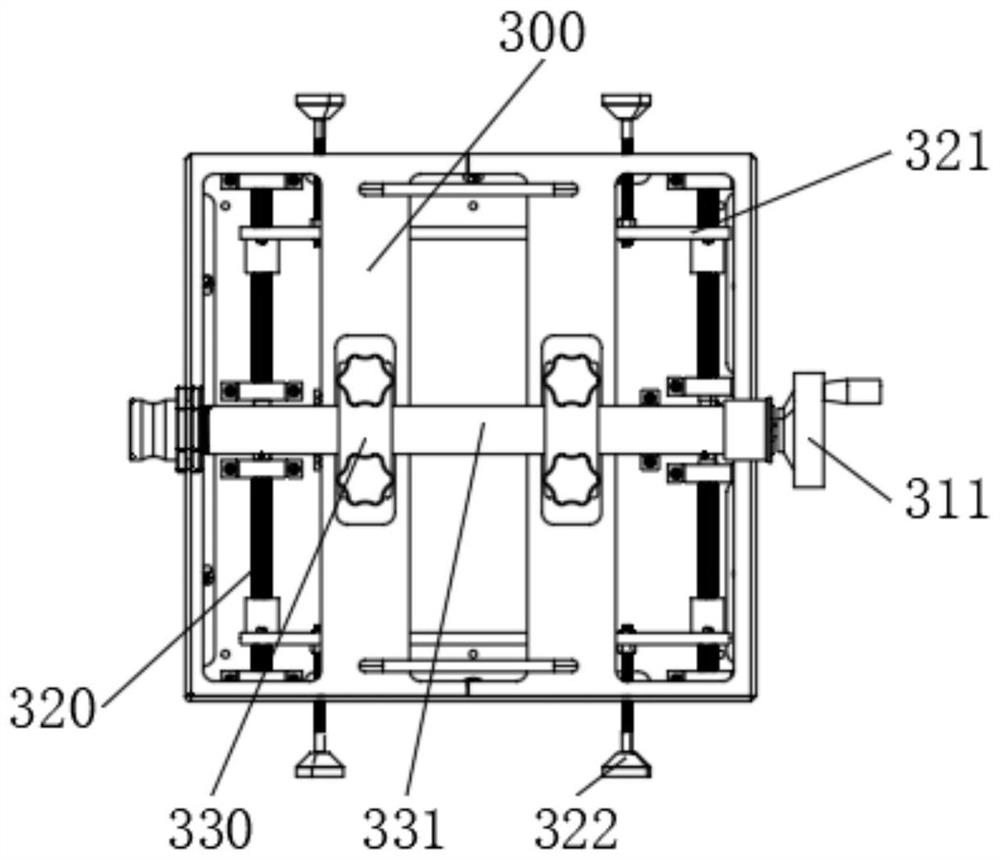

[0030] see Figure 1-3, the present invention provides a technical solution: an ultra-high pressure water cutting control actuator and control system for railway tunnels, including an executive trolley 100, a stainless steel braided hose 200, a support frame 300, a casing 400, a tube feeder 500, and a console 600 and the power mechanism 700, the stainless steel braided hose 200 is threaded on the left side wall of the pipe feeder 500, the support frame 300 is threaded on the other end of the stainless steel braided hose 200, and the casing 400 is fixedly connected to the support frame 300 through a water pipe. On the left side, the pipe feeder 500 is fixedly connected to the top left side of the execution trolley 100 through threads, the console 600 is plugged into the middle of the top of the execution trolley 100 through the support link 650, and the power mechanism 700 is fixedly connected to the top of the execution trolley 100 through bolts. On the right side of the top, ...

Embodiment 2

[0032] see figure 1 , Figure 4-5 and Figure 9-10 , the present invention provides a technical solution: an ultra-high pressure water cutting control actuator and control system for railway tunnels, including an executive trolley 100, a stainless steel braided hose 200, a support frame 300, a casing 400, a tube feeder 500, and a console 600 and the power mechanism 700, the stainless steel braided hose 200 is threaded on the left side wall of the pipe feeder 500, the support frame 300 is threaded on the other end of the stainless steel braided hose 200, and the casing 400 is fixedly connected to the support frame 300 through a water pipe. On the left side, the pipe feeder 500 is fixedly connected to the top left side of the execution trolley 100 through threads, the console 600 is plugged into the middle of the top of the execution trolley 100 through the support link 650, and the power mechanism 700 is fixedly connected to the top of the execution trolley 100 through bolts. ...

Embodiment 3

[0034] see figure 1 and Figure 4-9 , the present invention provides a technical solution: an ultra-high pressure water cutting control actuator and control system for railway tunnels, including an executive trolley 100, a stainless steel braided hose 200, a support frame 300, a casing 400, a tube feeder 500, and a console 600 and the power mechanism 700, the stainless steel braided hose 200 is threaded on the left side wall of the pipe feeder 500, the support frame 300 is threaded on the other end of the stainless steel braided hose 200, and the casing 400 is fixedly connected to the support frame 300 through a water pipe. On the left side, the pipe feeder 500 is fixedly connected to the top left side of the execution trolley 100 through threads, the console 600 is plugged into the middle of the top of the execution trolley 100 through the support link 650, and the power mechanism 700 is fixedly connected to the top of the execution trolley 100 through bolts. On the right si...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap