Large-span cast-in-place special-shaped stair construction method

A construction method and large-span technology, which are applied in the directions of stairs, stepped structures, formwork/formwork/work frame, etc., can solve the problem of difficulty in realizing mechanical rotation control of stair side formwork, difficulty in simultaneously improving the installation quality of stair treads, and failure to Realize problems such as overall formwork support of ladder beams and ladder plates, and achieve the effect of reducing difficulty, reducing damage, and achieving precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

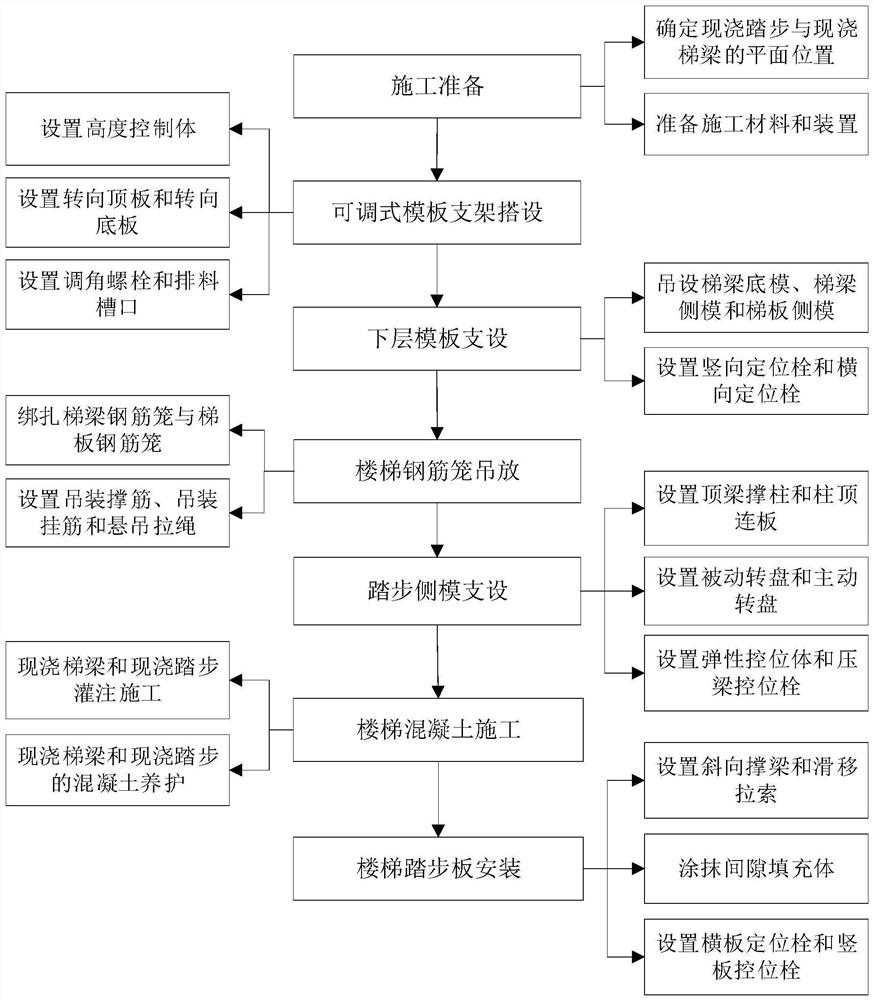

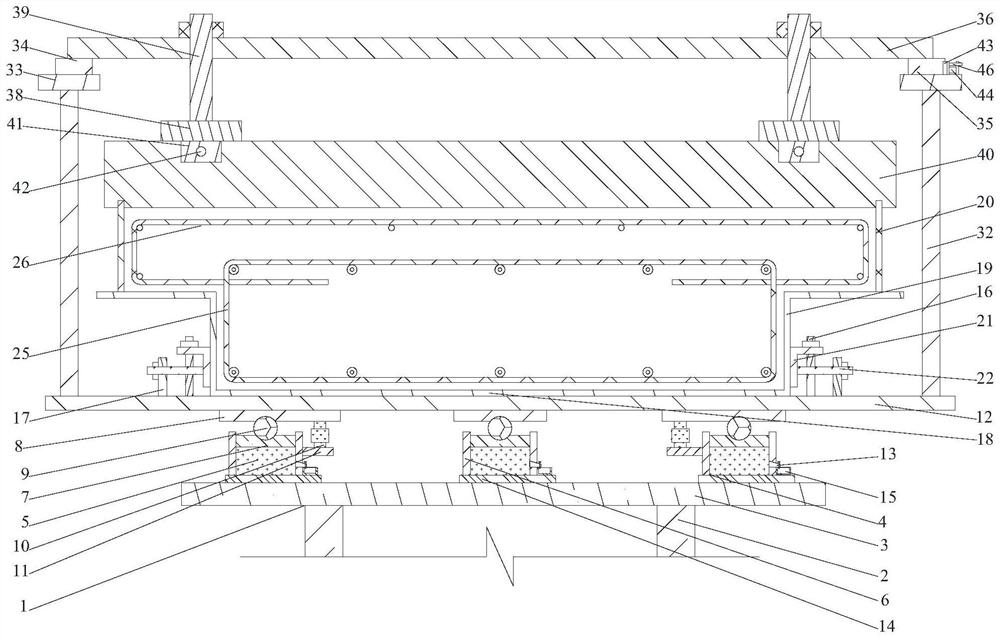

[0042] Such as Figure 1-2 As shown, the large-span cast-in-place special-shaped staircase construction method includes the following steps:

[0043] S100, construction preparation: survey and determine the plane position of the cast-in-place step 49 and the cast-in-place ladder beam 48, erect the bottom support frame 1 under the cast-in-place ladder beam 48, and prepare materials and devices required for construction;

[0044] In this step, the bottom frame 1 includes a frame top plate 3 and a plurality of frame uprights 2 arranged below the frame top plate 3 , and the height control body 4 is located on the upper surface of the frame top plate 3 .

[0045] S200. Erection of adjustable formwork brackets: set height control bodies 4 evenly spaced vertically along the upper surface of bottom support frame 1; fill support filler 5 in support barrel 6 of height control body 4, and then place steering base plate 7 on the support The upper surface of the filler 5, and the steering...

Embodiment 2

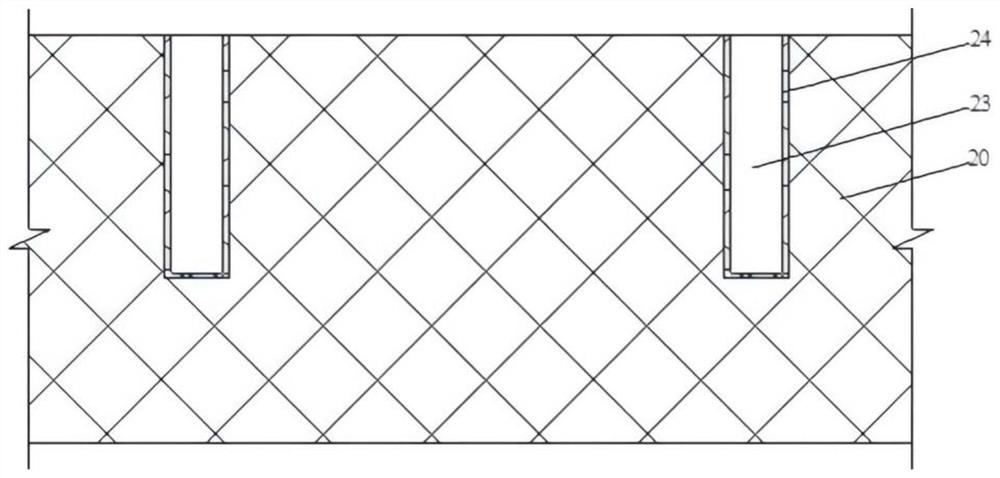

[0068] In order to make it easier for those skilled in the art to understand, on the basis of Embodiment 1, this embodiment illustrates the preference of each component of Embodiment 1 by way of example:

[0069] The bottom bracket 1 includes a bracket vertical rod 2 and a bracket top plate 3;

[0070] The support pole 2 is made of a steel pipe with a diameter of 100mm;

[0071] The support top plate 3 is rolled from a steel plate with a thickness of 10 mm.

[0072] The height control body 4 includes a control body bottom plate 14, a support barrel 6 and a recycling trough 15, and the support barrel 6 is vertically welded to the control body bottom plate 14, and the support filler 5 is filled in the support barrel 6;

[0073] The support filler 5 adopts medium and fine sand;

[0074] The support barrel 6 adopts a thickness of 10mm steel plate to be rolled into a cylindrical shape, with a height of 10cm and a diameter of 30cm. The control body bottom plate 14 is formed by a 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com