Film hole grid modification method

A technology of air film holes and grids, applied in geometric CAD, design optimization/simulation, etc., can solve the problems of wasting manpower and time resources, limiting the speed of optimization iterations, etc., to reduce iteration cycles, reduce manpower dependence, reduce effect of complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

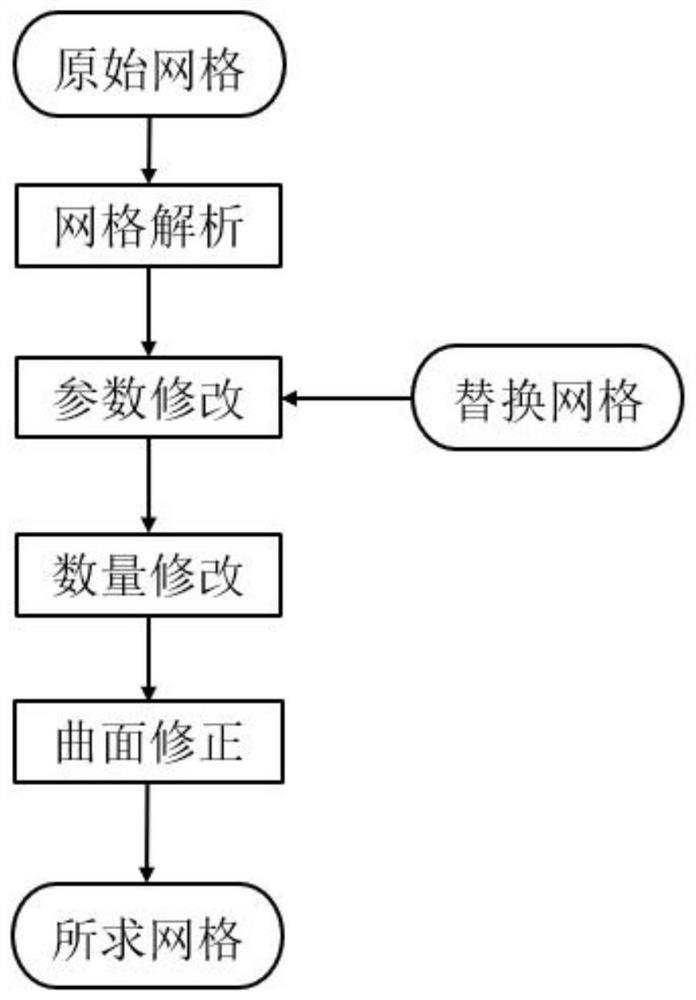

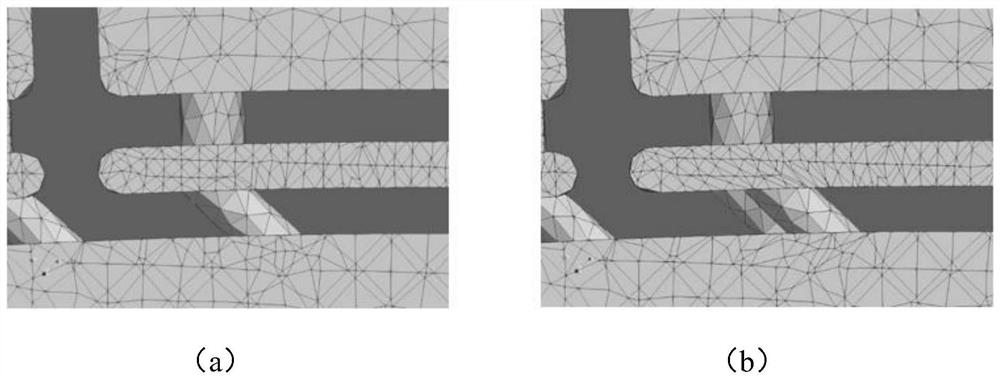

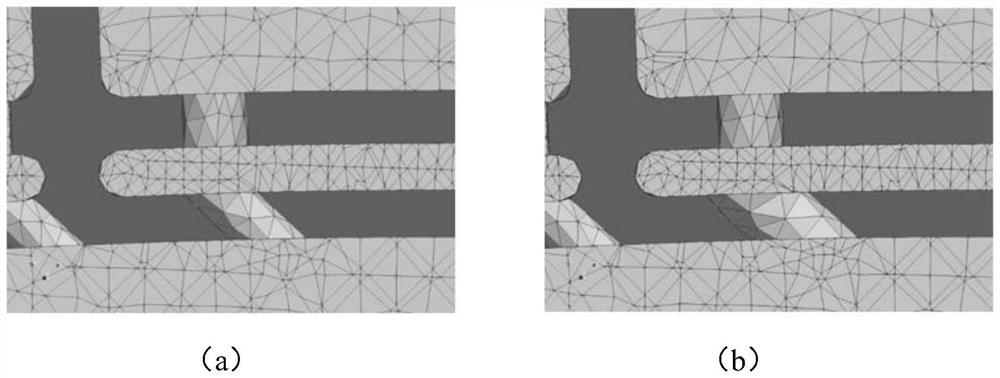

[0021] combine Figure 1 to Figure 5 Describe this embodiment, a method for modifying the grid of gas film holes. The method uses four modules: grid analysis module, parameter modification module, quantity modification module and surface correction module to perform grid analysis, parameter modification, quantity modification and surface modification respectively. Correction; the specific process is as follows:

[0022] 1. Grid analysis: read the existing grid file, and obtain the characteristic parameters of the target gas film hole and the surrounding grid point information through algorithm analysis through the position information of the target gas film hole.

[0023] The position information that needs to be input in this step consists of two parameters, the coordinates of the center of the sphere and the radius of the sphere. It is required that there are only target air film holes within the sphere.

[0024] The grid is composed of surfaces, the surface is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com