Assembly operation data set construction system and method based on virtual-real combination

A technology of assembly operation and combination of virtual and real, applied in the field of mechanics, can solve problems such as difficult data collection experiments, achieve strong interaction, ensure the quality of data sets, and improve the efficiency of data set construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

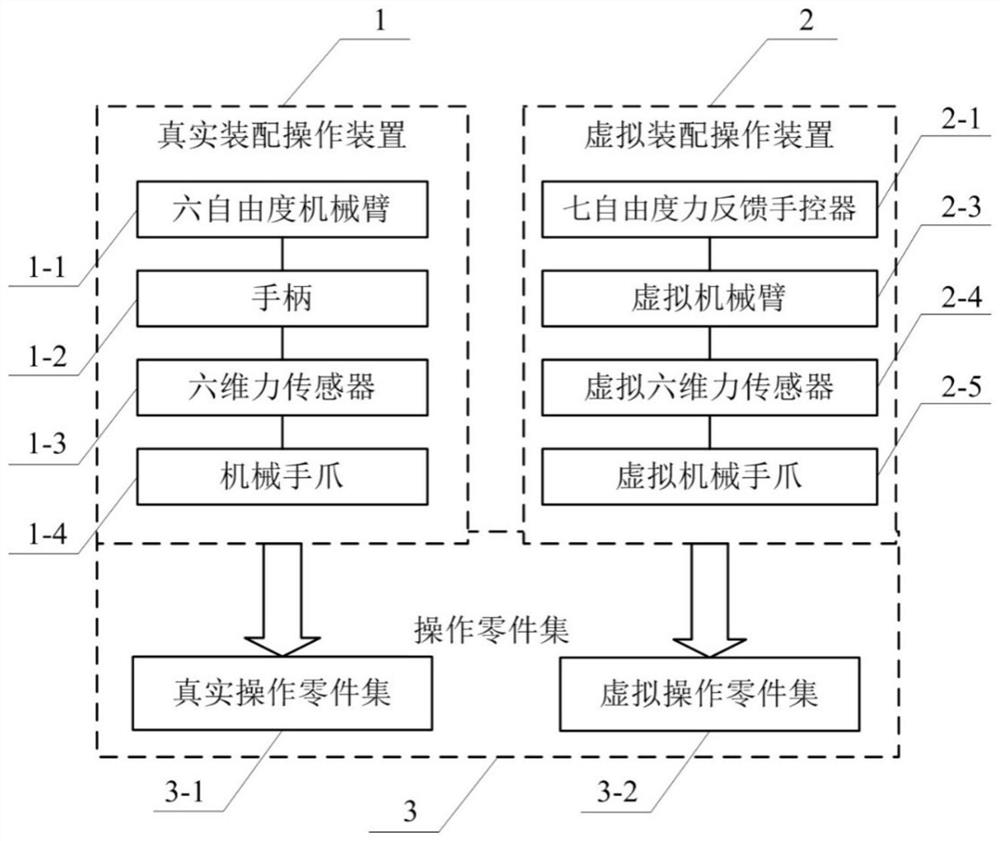

[0037] refer to figure 1 , an assembly operation data set construction system based on the combination of virtual and real is composed of a real assembly operation device 1, a virtual assembly operation device 2, and an operation part set 3. The real assembly operation device 1 is used to generate real assembly operation data, and the virtual assembly operation device 2 Used to generate virtual assembly operation data, the operation part set 3 provides operation objects for the real assembly operation device 1 and the virtual assembly operation device 2;

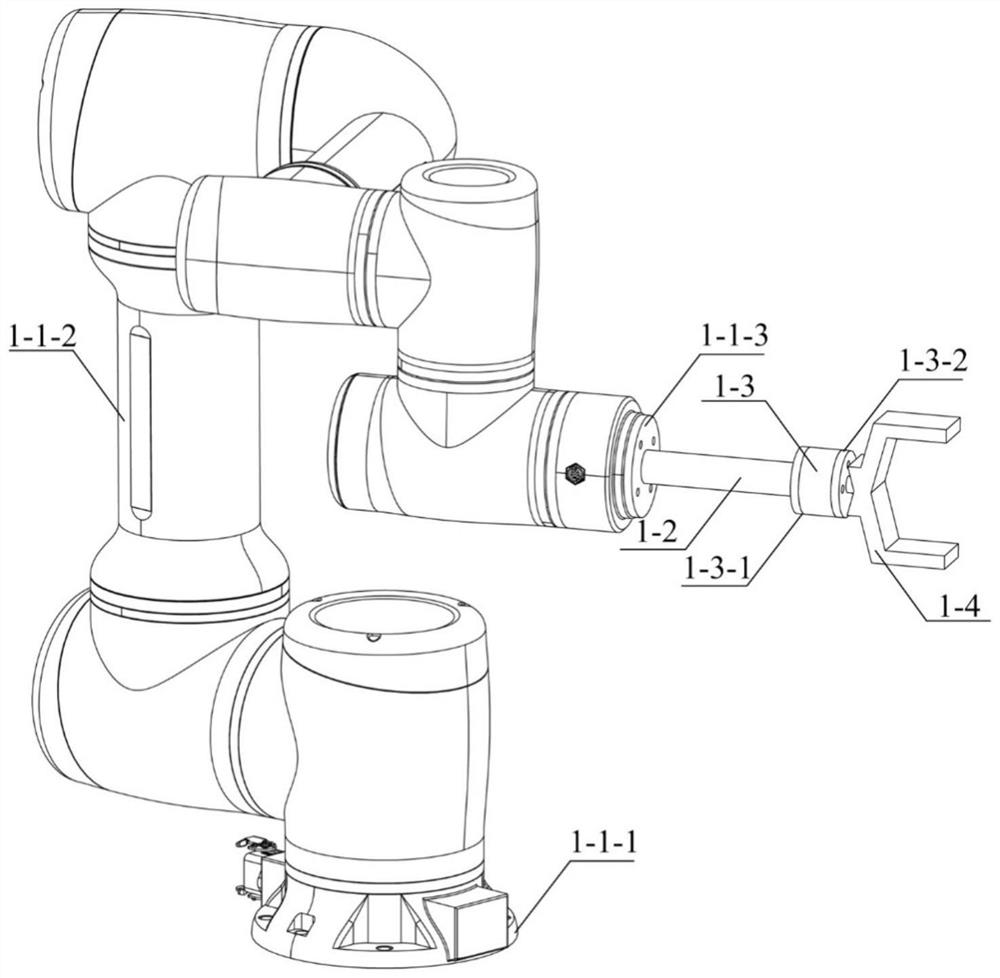

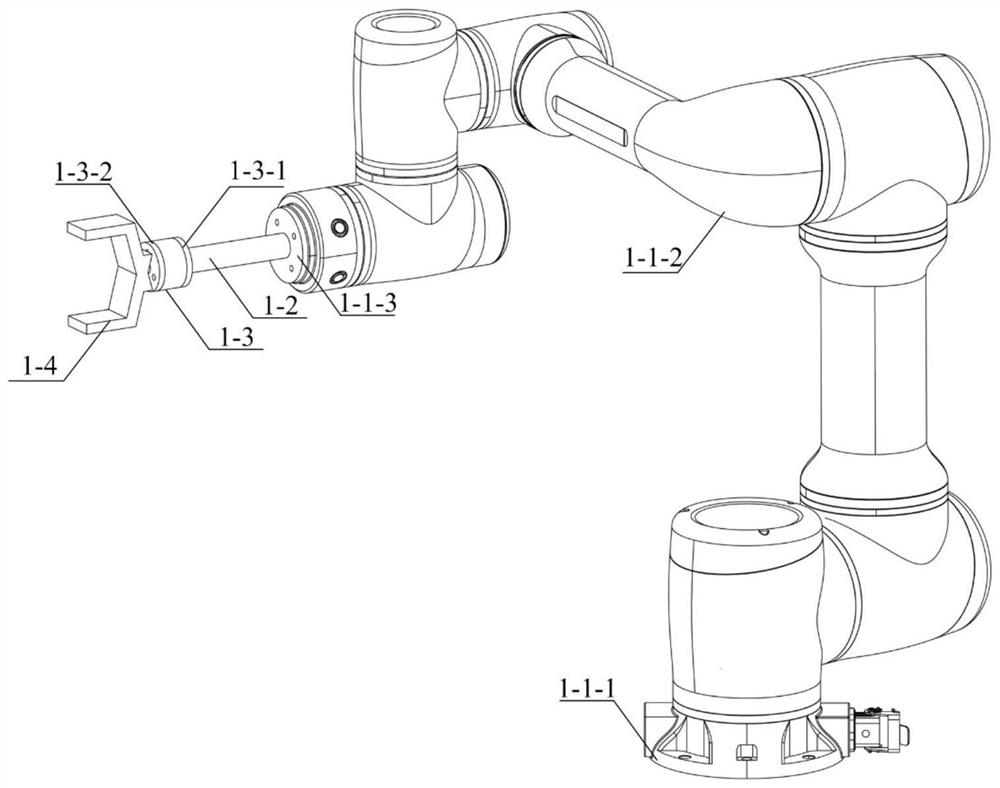

[0038] refer to figure 1 , figure 2 and image 3 , the real assembly operation device 1 includes a six-degree-of-freedom mechanical arm 1-1, a handle 1-2, a six-dimensional force sensor 1-3, and a mechanical gripper 1-4. The six-degree-of-freedom mechanical arm 1-1 includes a base 1-1-1, a body 1-1-2, and an end flange 1-1-3, and the base 1-1-1 is fixed on an installation platform. The body 1-1-2 is installed on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com