Egg yolk lecithin extraction equipment with high extraction rate

A technology of egg yolk lecithin and extraction equipment, which is applied in the field of egg yolk lecithin extraction, can solve the problems of troublesome, time-consuming, lack of materials, and inconvenient for workers to operate, and achieves the effects of reducing work pressure and uniform material distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

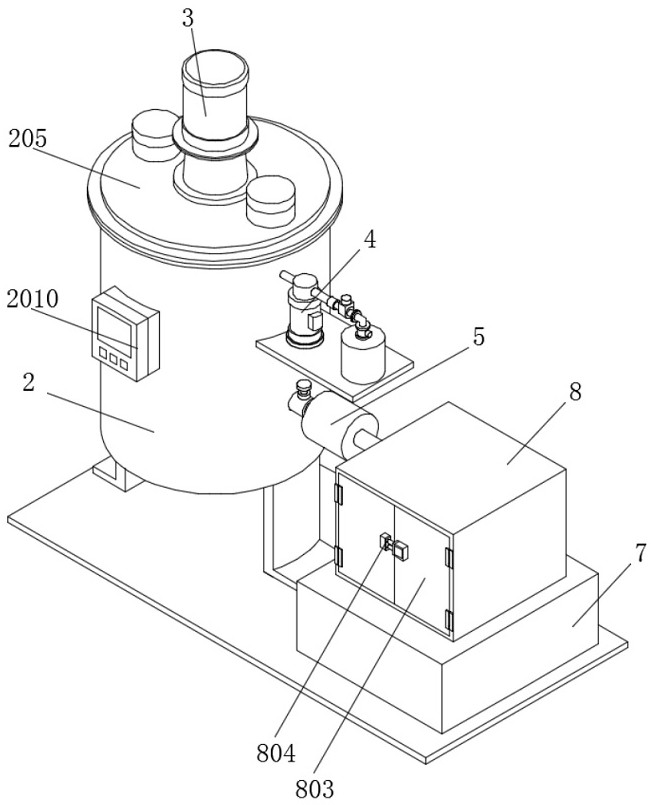

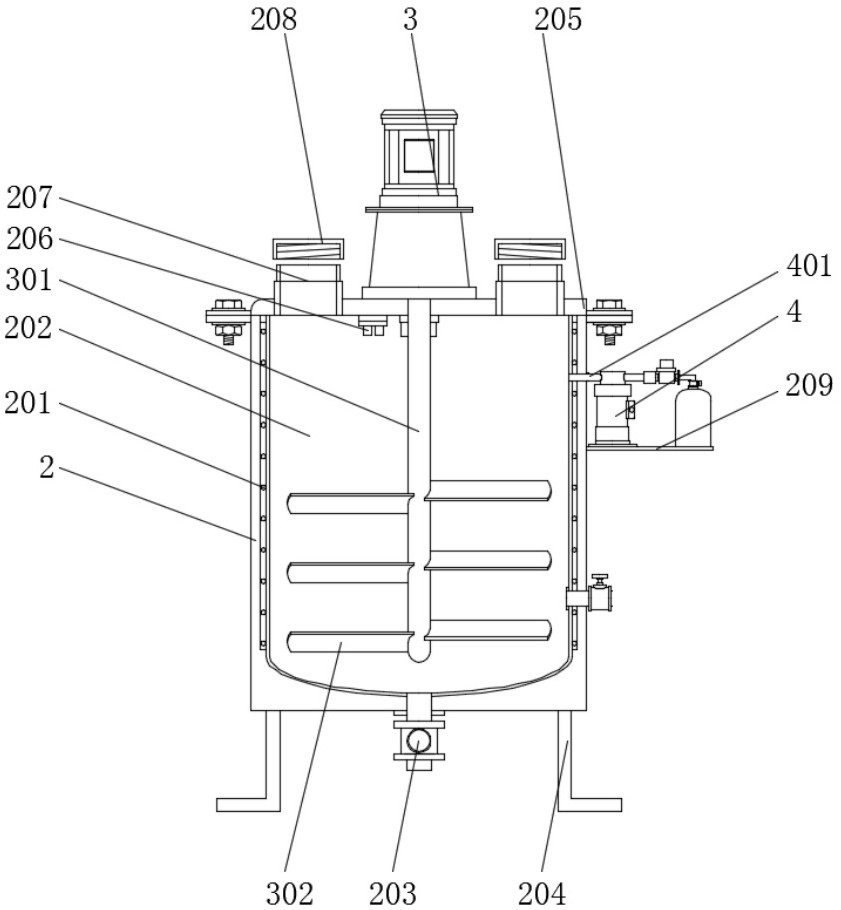

[0041] Embodiment 1 includes a base plate 1, a support plate 204 is installed on the top of the base plate 1 through bolts, a mixing box 2 is installed on the top of the support plate 204, a heating pipe 201 is installed on the inner wall of the mixing box 2, and the heating An inner box 202 is installed inside the pipe 201, and a discharge valve 203 is installed through the bottom wall of the mixing box 2 and the inner box 202, which is used to discharge impurities from the discharge valve 203 after the work is completed, so as to facilitate workers to clean up the equipment , the inner side of the closing cover 205 is penetrated with a feeding port 207 installed, and the feeding port 207 is located on both sides of the motor 3, the top thread of the feeding port 207 is provided with a closing plug 208, and the bottom of the closing cover 205 is equipped with a first temperature and pressure sensor 206, The front of the mixing box 2 is equipped with a controller 2010, the top ...

Embodiment 2

[0043] Embodiment 2 includes a bottom plate 1, a booster pump 4 is installed on the top of the support platform 209, and an air blowing pipe 401 is installed on the output end of the booster pump 4, and the air blowing pipe 401 runs through a part of the mixing box 2 and the inner box 202. On the side inner wall, a ventilation pipe 402 is installed at the input end of the air blowing pipe 401, a closing valve 403 is installed at the input end of the ventilation pipe 402, a butt pipe 404 is installed at the input end of the closure valve 403 through bolts, and a switch is installed at the bottom end of the butt pipe 404 Valve 405, nitrogen tank 406 is installed at the bottom of switch valve 405, and nitrogen tank 406 is installed on the bottom of support platform 209, booster pump 4 runs and produces suction, sucks the air inside vent pipe 402, closes valve 403 and switch valve 405 simultaneously Open, the nitrogen tank 406 outputs gas to the inside of the butt pipe 404 through ...

Embodiment 3

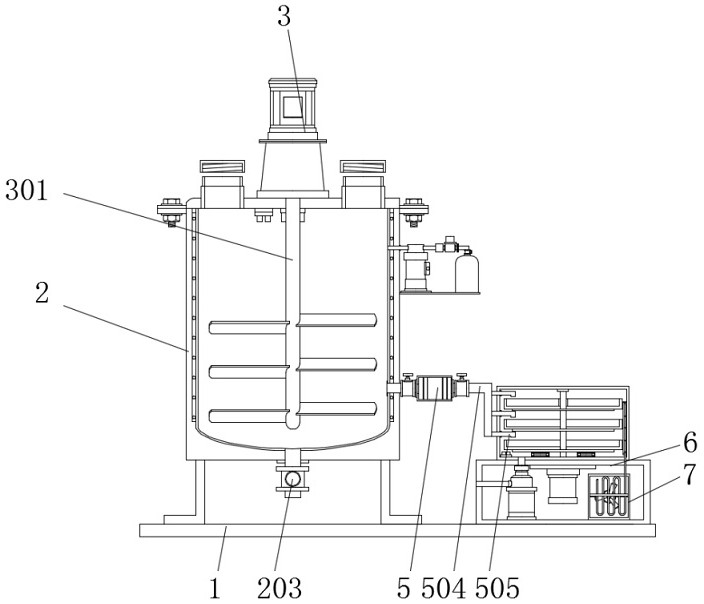

[0045] Embodiment 3, including the bottom plate 1, a first control valve 502 is installed through one side of the outer wall of the mixing box 2, and the first control valve 502 is located below the support platform 209, and the output end of the first control valve 502 A purification box 5 is installed, a filter screen 501 is installed on the inside of the purification box 5, a second control valve 503 is installed at the output end of the purification box 5, and a delivery pipe 504 is installed at the output end of the second control valve 503, so Three sets of equidistantly arranged output pipes 505 are installed through the outer wall of the delivery pipe 504. The first control valve 502 and the second control valve 503 are opened to ensure the internal connection of the device. The lecithin passes through the first control valve from the inside of the inner box 202. 502 to the inside of the purification box 5. During the process of material movement, the material is filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com