Intelligent medicine bottle conveyor

A conveyor and medicine bottle technology, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of broken medicine bottles, uneven feeding, lack of materials, etc., to avoid uneven feeding, The effect of uniform and stable bottle feeding and improved conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

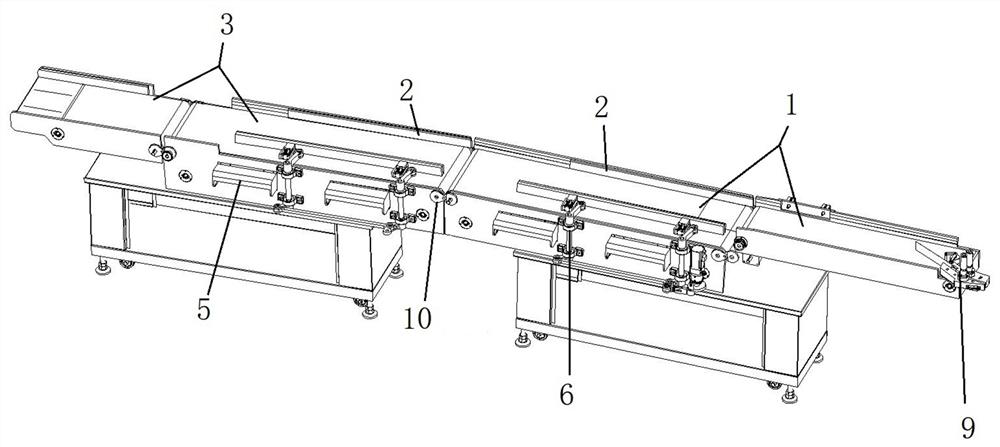

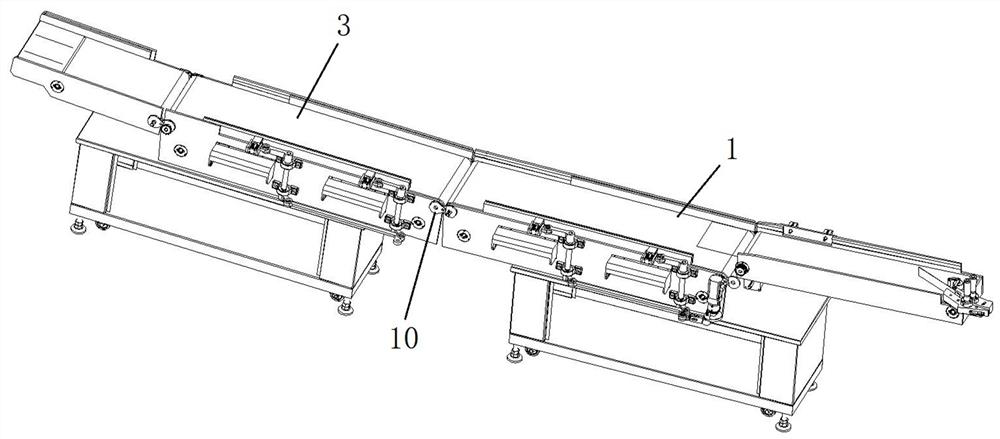

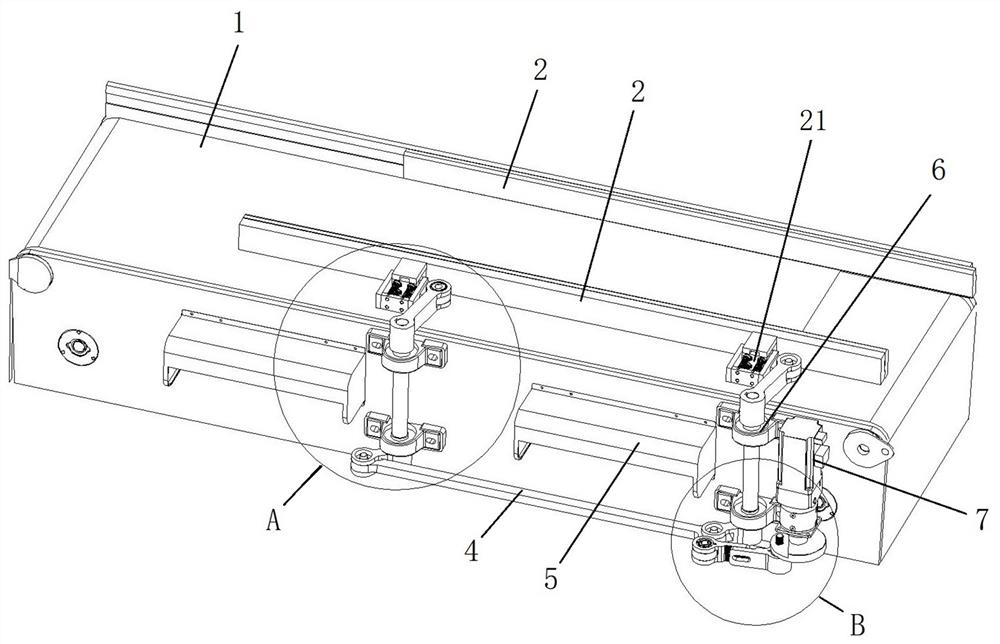

[0035] like Figure 1-2 As shown, the present invention proposes an intelligent medicine bottle conveyor, which includes a feeding conveyor belt 1 and a feeding conveyor belt 3, and the bottoms of the two conveyor belts are installed on the corresponding bases through supporting components (not shown), The support assembly is used to adjust the support height at both ends of the two conveyor belts. The discharge end of the feeding conveyor belt 1 is connected with the feeding end of the unloading conveyor belt 3 through an angle connection mechanism. The angle connection mechanism includes two sets of angle adjustment plates 10 respectively installed on the casings of the feeding conveyor belt 1 and the unloading conveyor belt 3 respectively, and the two angle adjustment plates 10 are hinged together. When there is a height difference between the front and rear ends of the conveyor, the height of the two ends of the conveyor belt can be changed by adjusting the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com