Pull-type glass transfer device

A transfer device, traction technology, applied in transportation and packaging, conveyor objects, furnaces, etc., can solve problems such as company property loss, personnel safety hazards, and uniformity of difficult force, and achieve the effect of convenient transfer work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

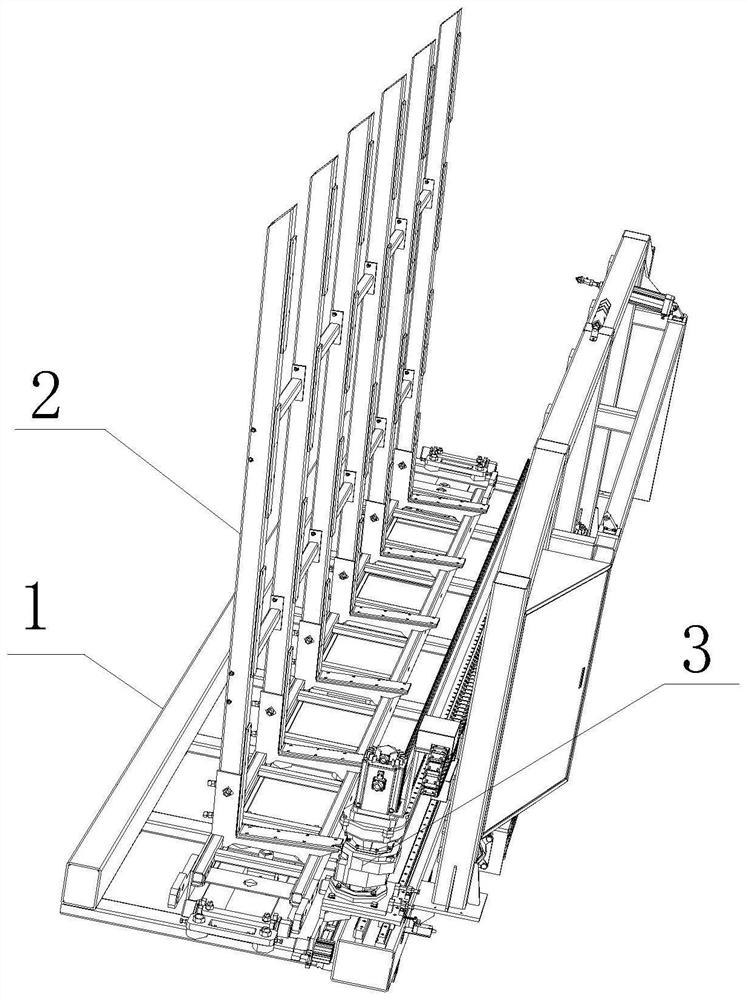

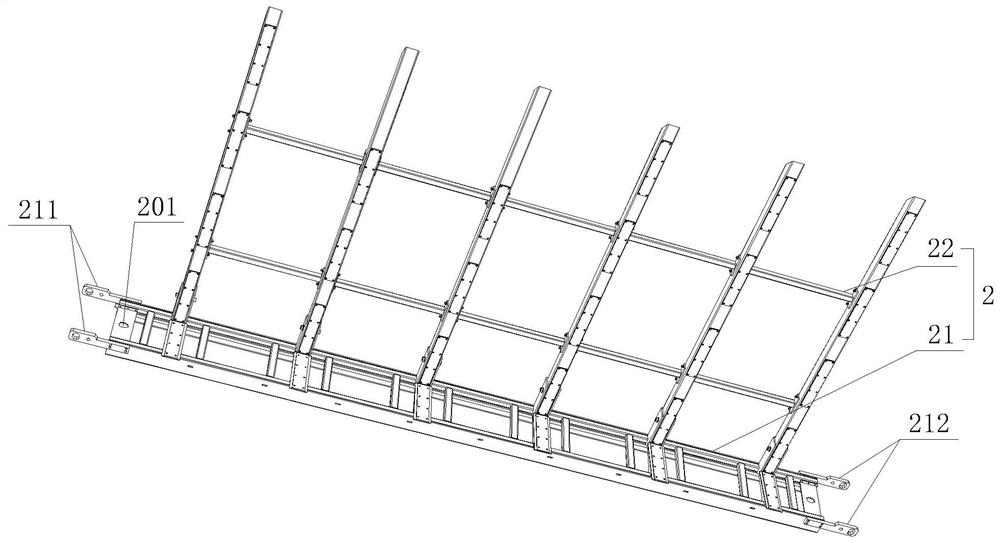

[0028] refer to Figure 1-2 , a kind of traction type glass transfer device that the present invention proposes, comprises: transfer vehicle 1 and the glass frame 2 that is used to place glass, wherein:

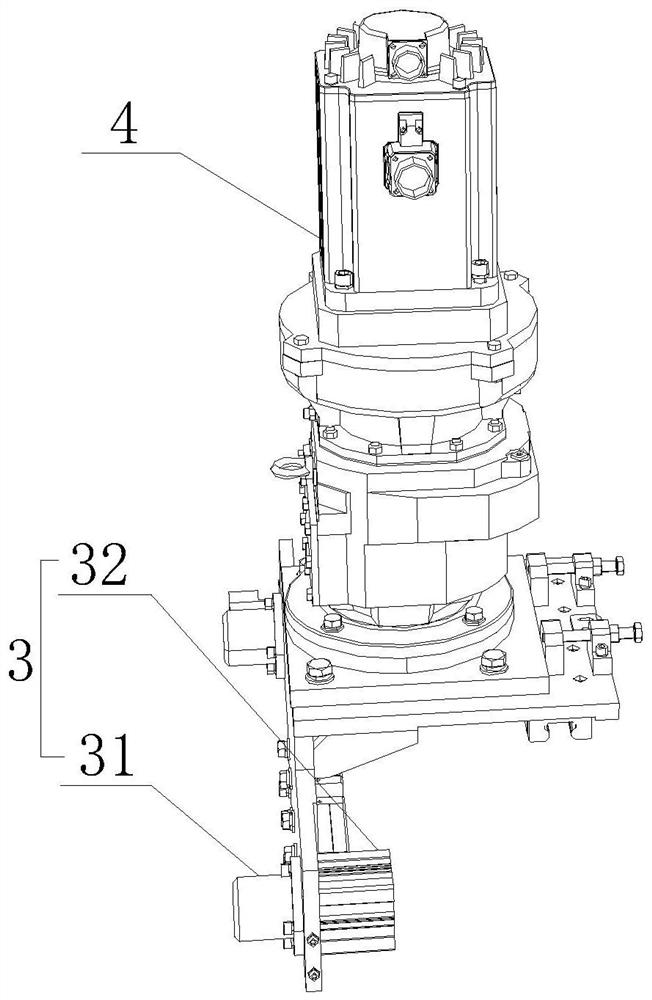

[0029] The transfer vehicle 1 is provided with a track and a traction mechanism located on one side of the track. At least one end of the track is open to form a butt end for the glass shelf 2 to slide in and out; the traction mechanism includes a latch assembly 3 and a drive assembly 4; the latch assembly 3 includes a pin shaft 31 and a first power unit 32, and one end of the pin shaft 31 Facing the track, the first power unit 32 is connected with the pin shaft 31 to drive the pin shaft 31 to expand and contract axially; A jack for the pin shaft 31 to be inserted is provided. The specific usage is as follows:

[0030] When blanking, the transfer car 1 will be moved so that the track on the transfer car 1 is docked with the track on the designated processing line, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com