Automatic edge aligning and rolling inspection system for cloth

An automatic, side-rolling technology, which is applied in the inspection of textile materials, winding strips, thin material processing, etc., can solve the problems of laborious inspection and different white light transmission effects of fabrics, achieve a stable contact state, and improve inspection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

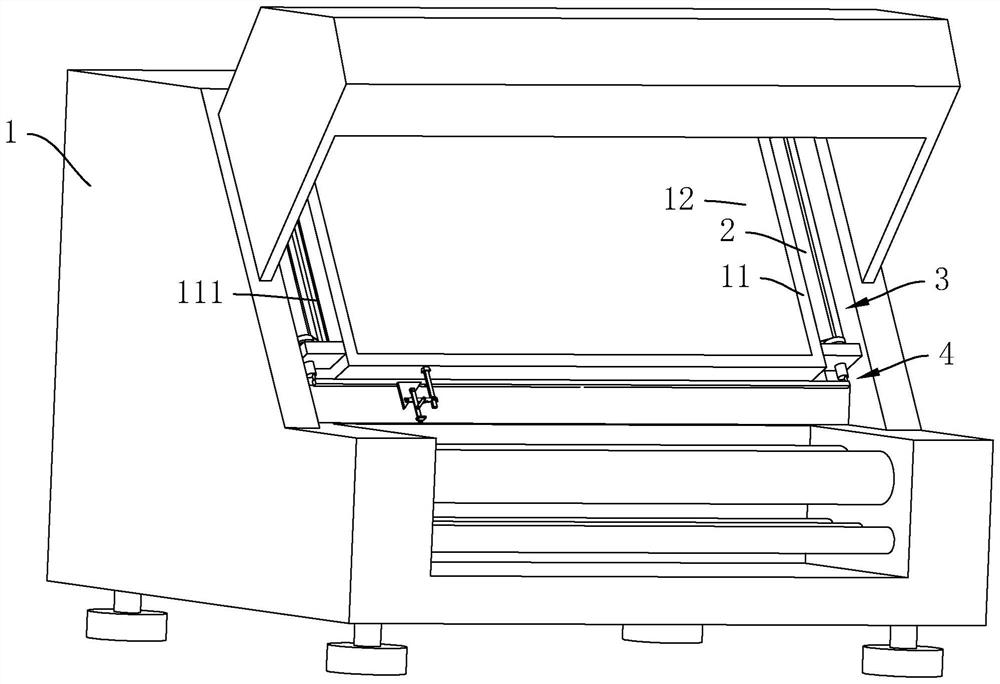

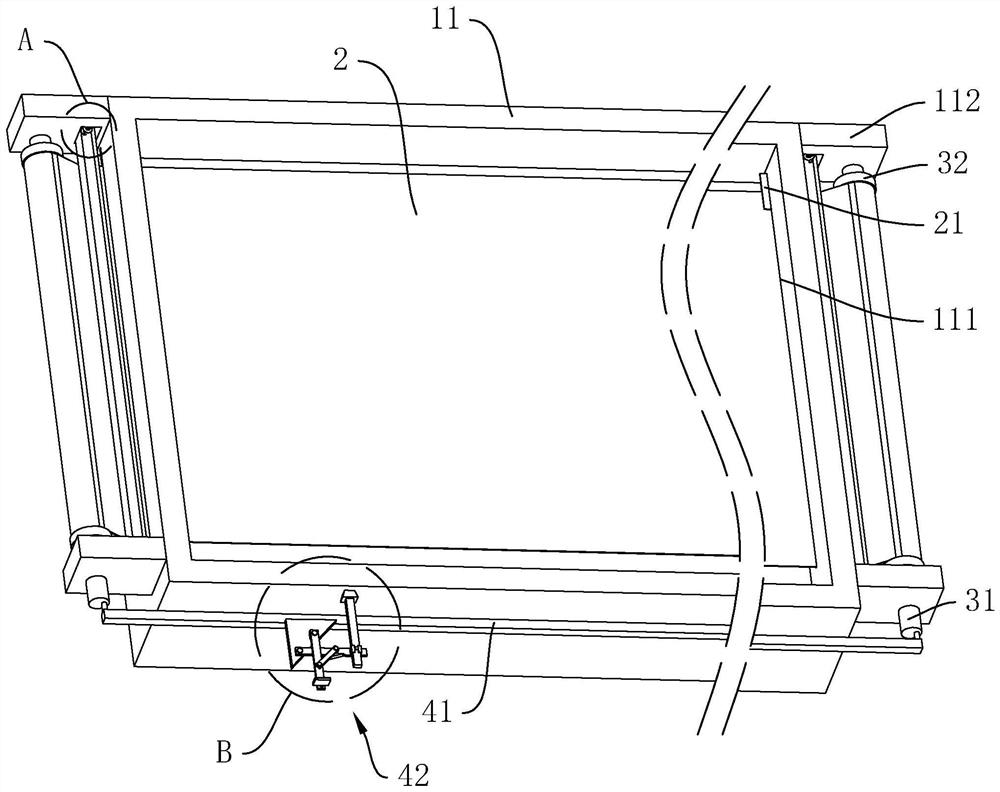

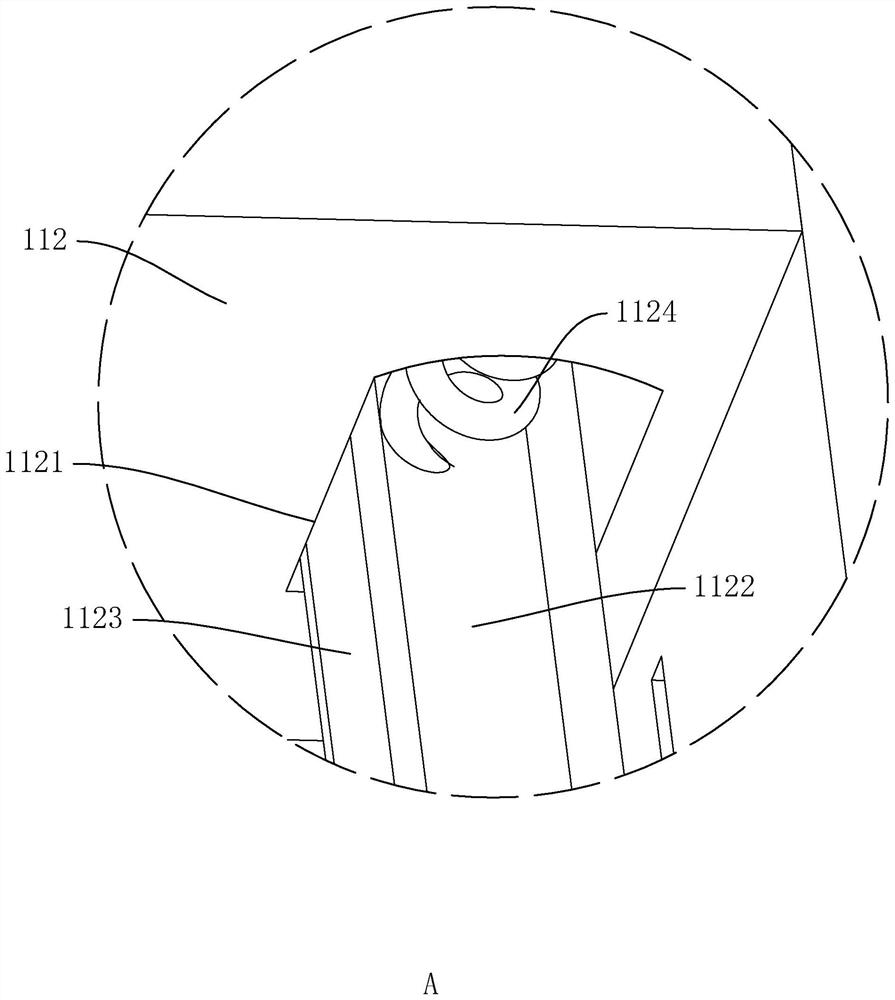

[0033] The following is attached Figure 1-4 The application is described in further detail.

[0034] The embodiment of the present application discloses a cloth automatic edge rolling inspection system. refer to figure 1 , the cloth automatic side-to-side rolling inspection system includes a frame 1, an inspection frame 11 is connected by bolts on the frame 1, a light source is arranged in the inspection frame 11, the light source is white light, and a light-transmitting plate 12 is fixed on the inspection frame 11 by bolts ; The light source penetrates from the light-transmitting plate 12, and when the cloth passes through the light-transmitting plate 12, the operator checks through the light transmitted through the cloth.

[0035] refer to figure 1 , both ends of the test frame 11 in the horizontal direction are provided with an adjustment assembly 3, and the adjustment assembly 3 is provided with a drive assembly 4; Adjustment hole 111, the light-transmitting adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com