Vertical falling locking mechanism for rail transportation

A locking mechanism and rail transportation technology, applied in the field of rail transportation, can solve the problems of high-speed falling, large impact force, stall of transport load-bearing boxes, etc., and achieve the effects of increasing the contact area, increasing the friction force, and reducing the falling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

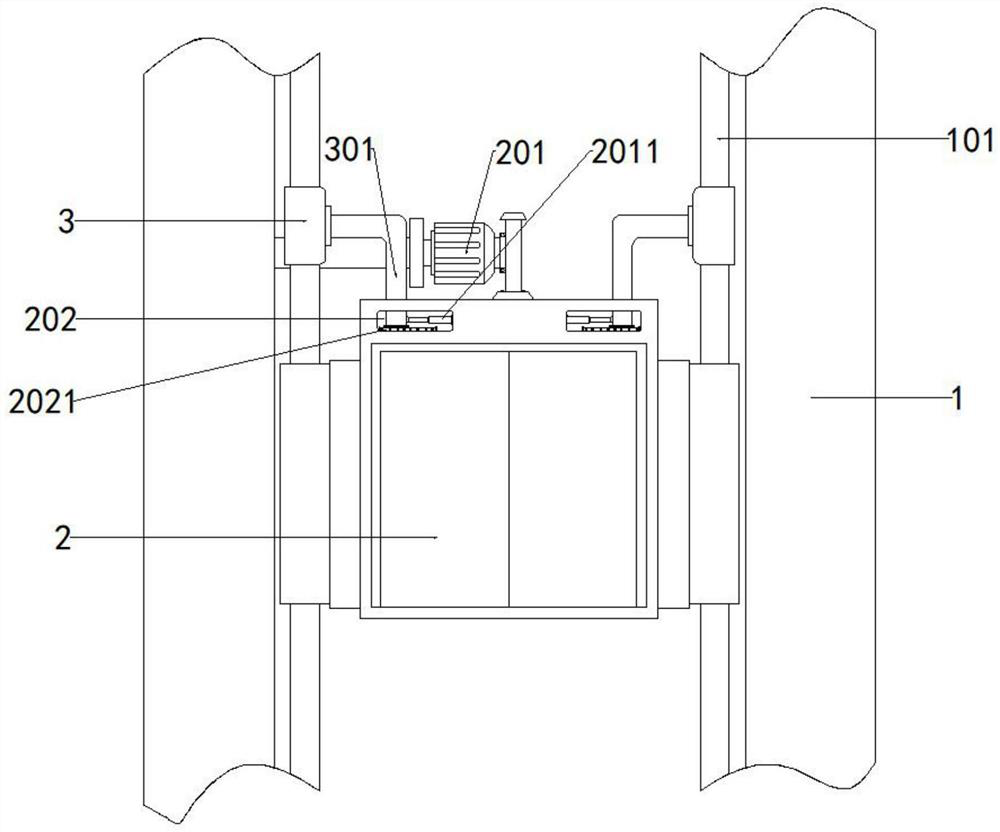

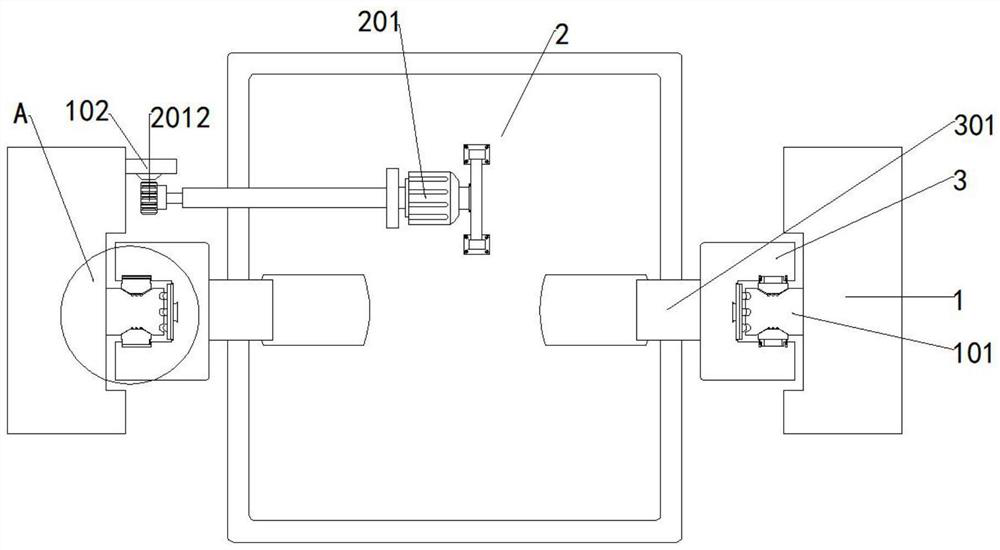

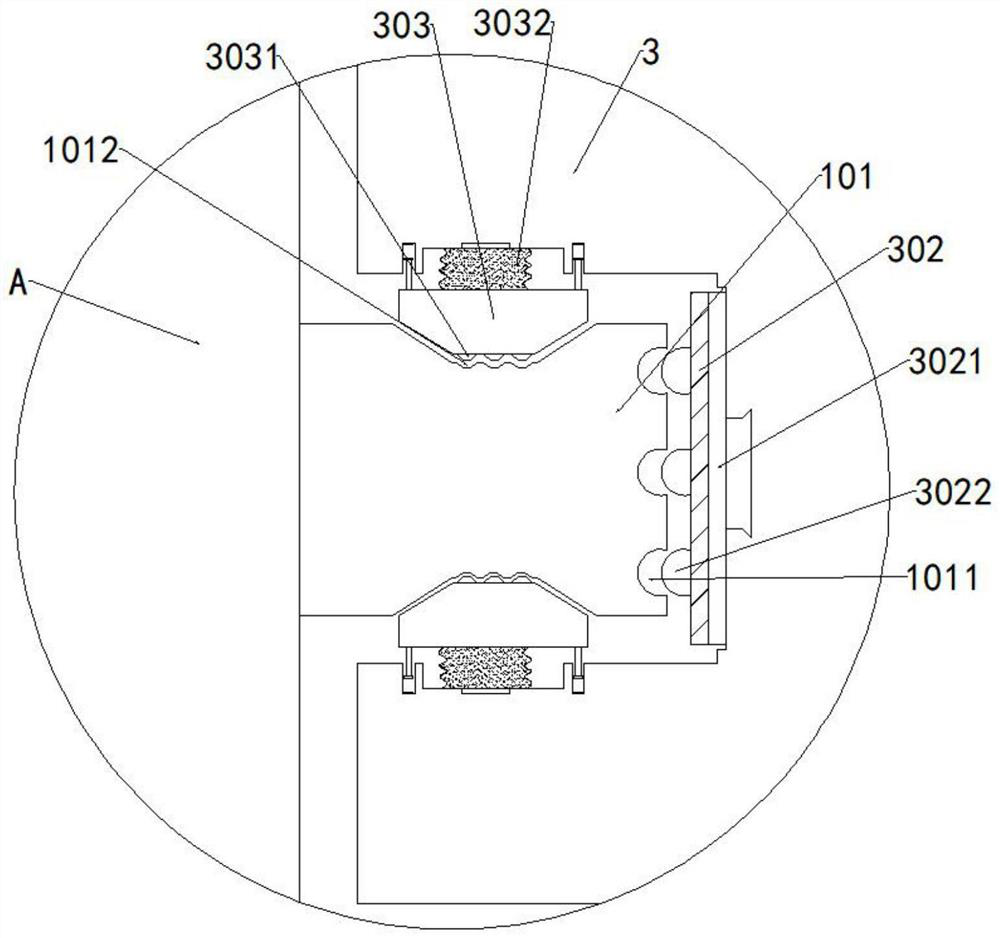

[0026] as attached figure 1 to attach Figure 5 Shown:

[0027] The present invention provides a vertical fall locking mechanism for rail transportation. The vertical fall locking mechanism for rail transportation includes a load-bearing wall 1, a track 101 and a load-bearing box 2. The number of load-bearing walls 1 is two and symmetrical to each other. 1. Rails 101 are fixedly installed on opposite sides, and load-bearing boxes 2 are slidably connected between the rails 101, and a stall locking mechanism is arranged above the load-bearing boxes 2.

[0028] Wherein, the stall locking mechanism includes a rack 102, a generator 201, an electric telescopic rod 2011, a gear 2012, a groove 202, a sliding rail 2021, a locking clip 3 and a connecting rod 301;

[0029] A generator 201 is rotatably connected above the load-bearing box 2, a gear 2012 is fixedly installed at the shaft joint of the generator 201, a rack 102 is fixedly installed on one side of the load-bearing wall 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com