Novel PVC pipe and processing method thereof

A PVC pipe material and processing method technology, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve problems such as troublesome use, and achieve the effect of improving flame retardant effect and anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

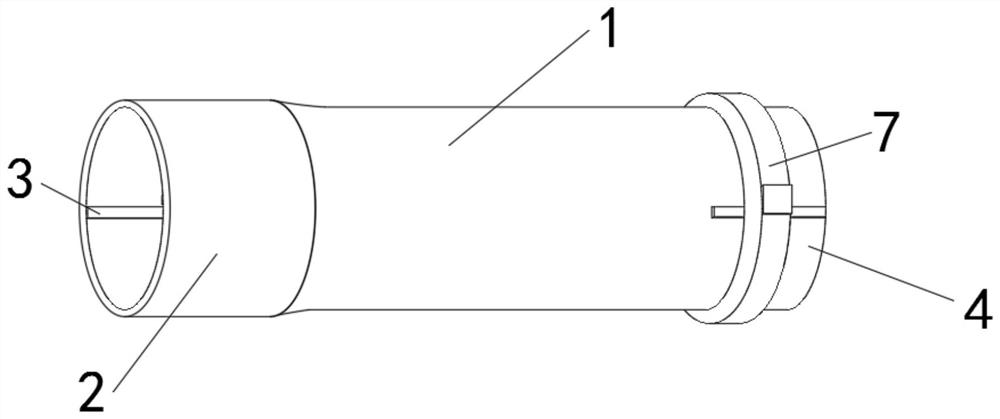

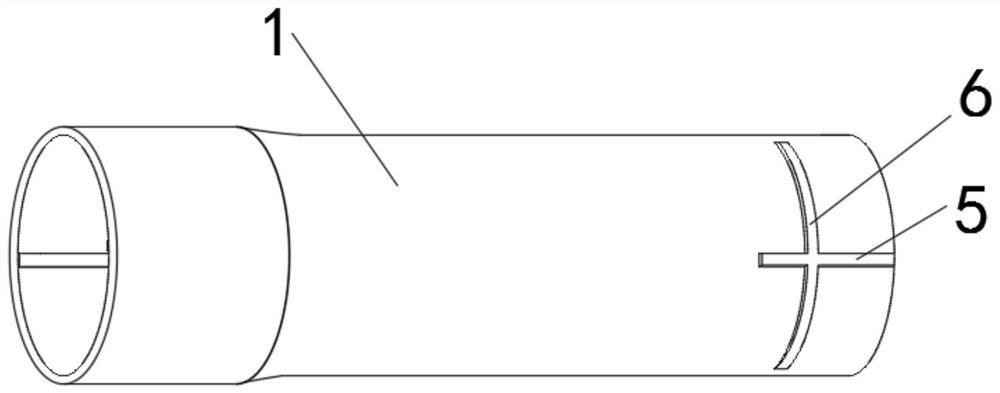

[0035] The following is attached Figure 1-5 The present invention is described in further detail.

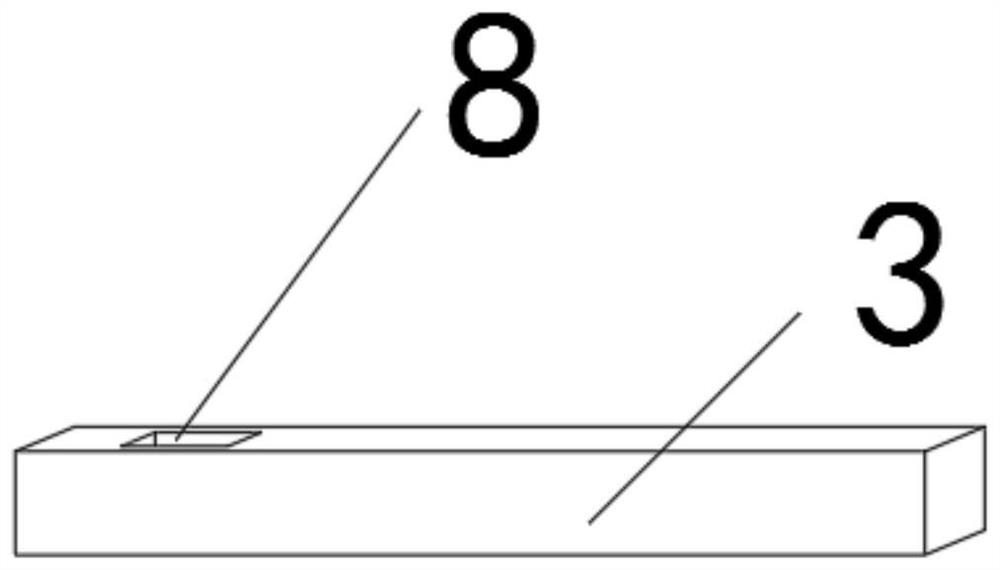

[0036] A new type of PVC pipe disclosed by the present invention comprises a main pipe body 1, a connecting pipe head 2 is arranged on the left side of the main pipe body 1, a connecting rod 3 is arranged inside the connecting pipe head 2, and a connecting pipe tail 4 is arranged on the right side of the main pipe body 1, The inner diameter of the connecting pipe head 2 is the same as the outer diameter of the connecting pipe tail 4. When two pipes need to be connected, the connecting pipe tail 4 of one PVC pipe is inserted into the connecting pipe head 1 of another PVC pipe, and the two PVC pipes are connected. Pipes are connected.

[0037] The outer wall of the connecting pipe tail 4 is provided with an insertion groove 5 and a limiting groove 6. The insertion groove 5 and the limiting groove 6 are arranged in the shape of a "cross", and the outer wall of the connecting pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap