Concrete full-pipe chute transportation hanging flower pipe spray cooling system and method

A concrete and full-pipe technology, which is applied in control/regulation systems, temperature control, construction, etc., can solve problems such as transportation temperature rise, achieve the effects of reducing transportation temperature rise, low cost, and preventing temperature from exceeding the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

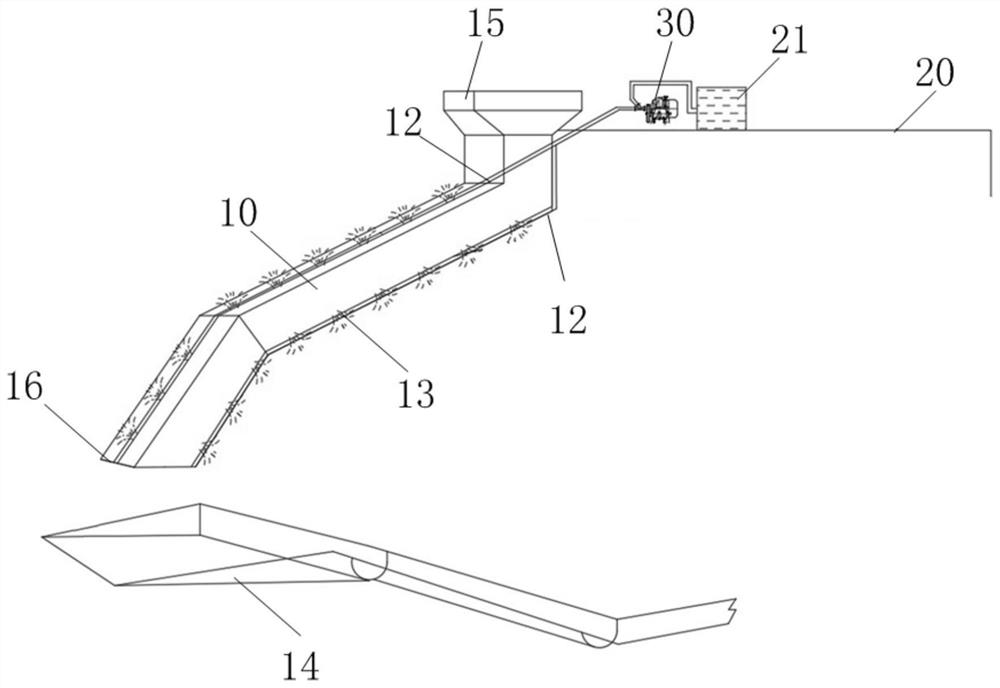

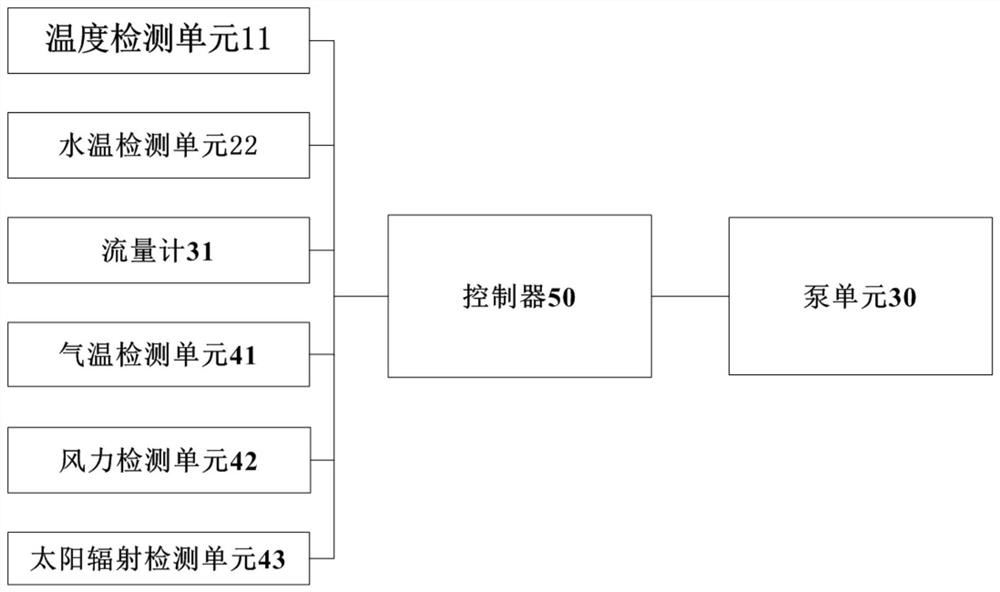

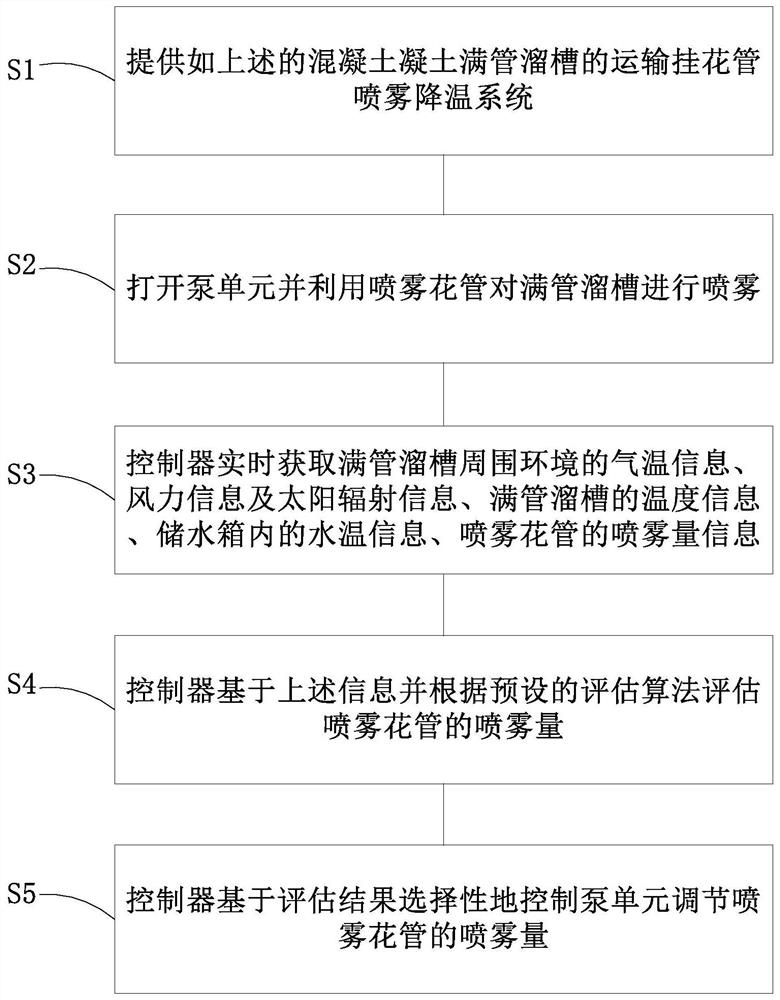

[0037] The test has proved that in a construction area the ambient temperature is about 28°C, the full-pipe chute 10 transports concrete for 3 to 5 minutes, and the concrete entry temperature detected by the discharge port 16 of the full-pipe chute 10 is higher than that detected by the unloading platform 20. 1.1~1.6℃. There are two main factors that cause the temperature of the concrete to rise during the transportation of the full-pipe chute 10 : one is solar radiation heat, and the other is the frictional heat generated between the concrete and the bottom of the full-pipe chute 10 . During the transportation of the full-pipe chute 10 , the purpose of reducing the temperature rise during transportation can be achieved by spraying the full-pipe chute 10 . Below in conjunction with the accompanying drawings, the present invention provides a concrete full-pipe chute transportation hanging flower pipe spray cooling system and method.

[0038] See attached figure 1 and figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com