Aero-engine service life prediction method based on improved LSTM

An aero-engine and life prediction technology, applied in the field of aero-engine, can solve the problem of high complexity of feature extraction model, achieve the effect of strong generalization ability and feasibility, reduce complexity, and improve the effect of life prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

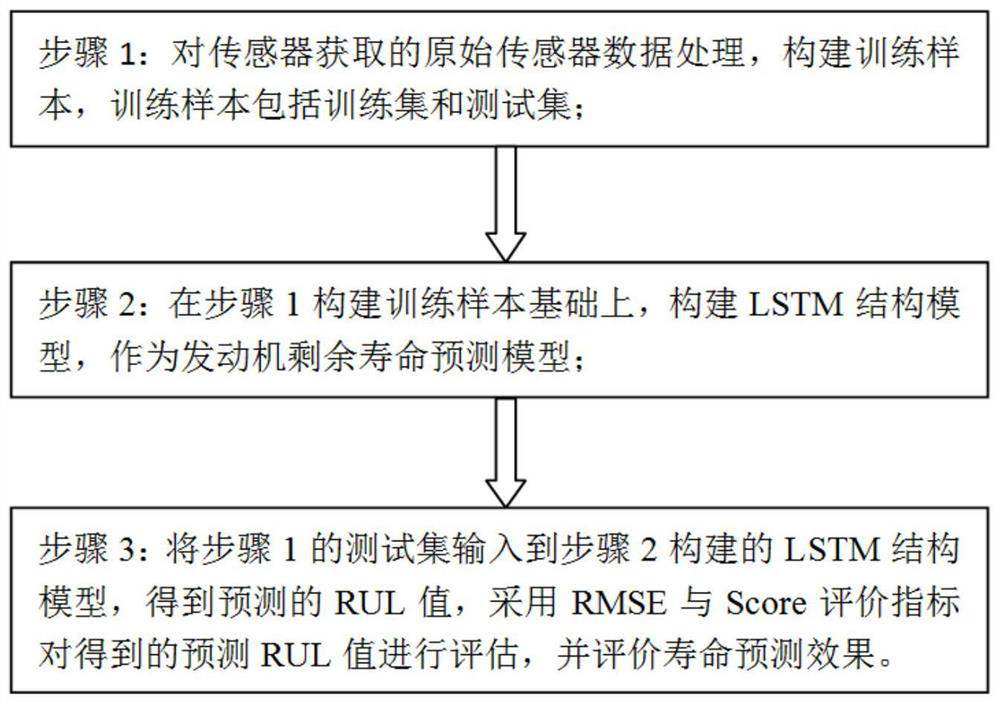

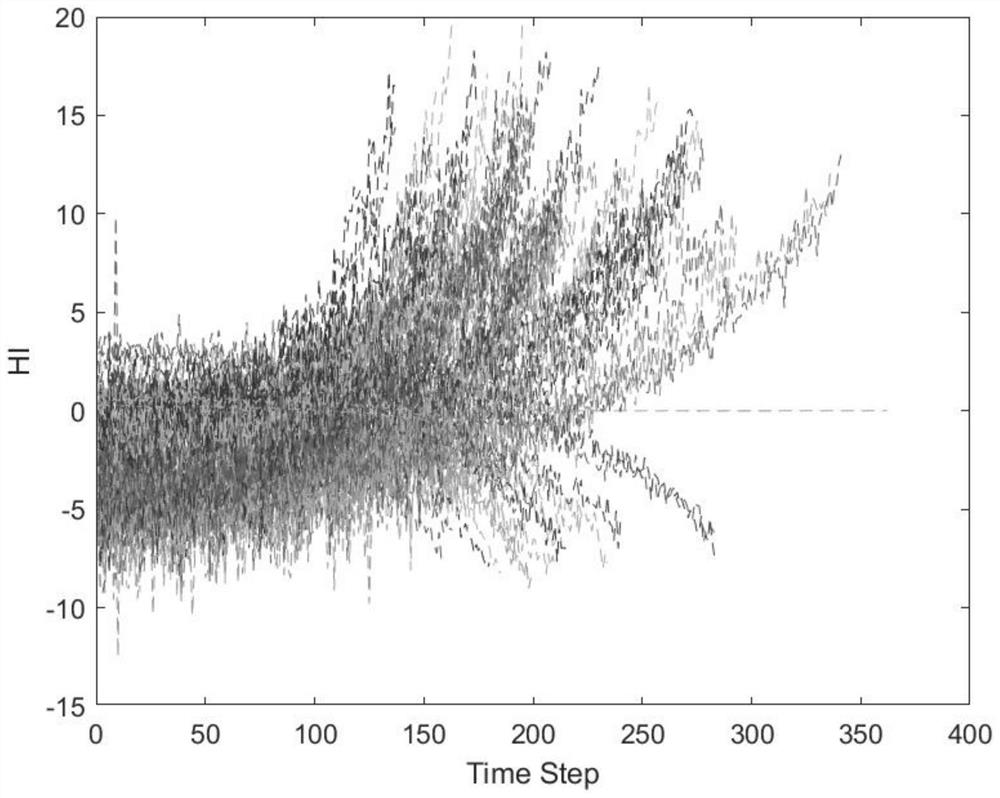

[0073] Refer to attached Figure 1-6 As shown, an aero-engine life prediction method based on improved LSTM includes the following steps:

[0074] Step 1: Process the raw sensor data acquired by the sensor and construct a training sample. The training sample includes a training set and a test set. The specific steps include:

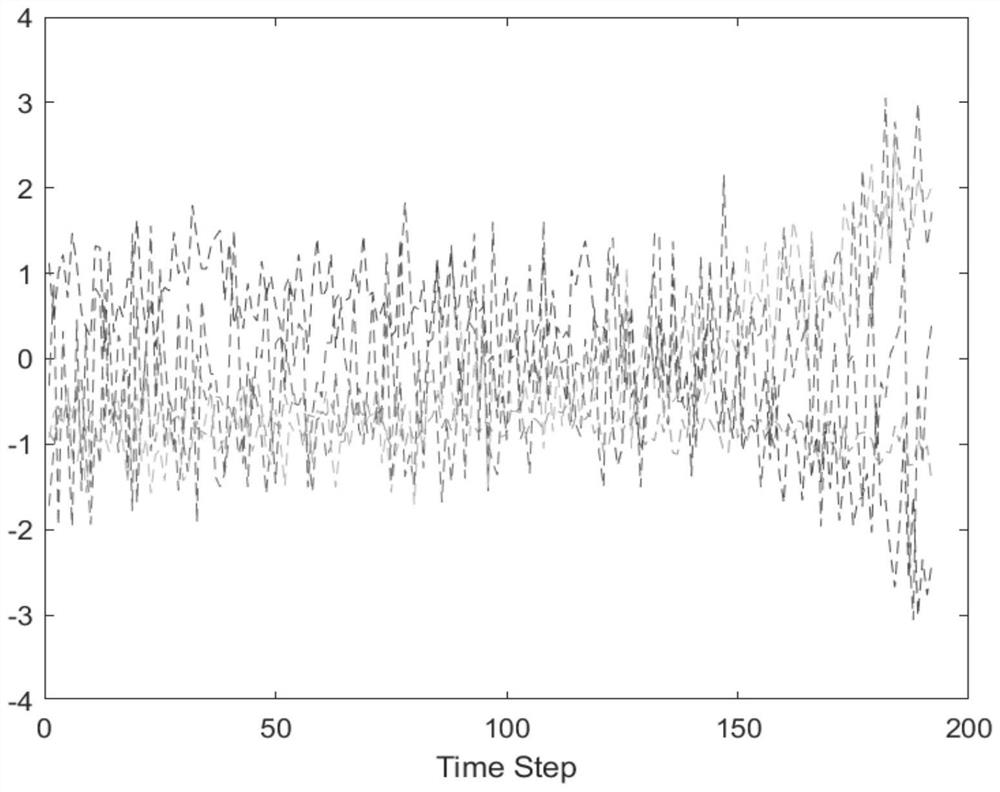

[0075] Step 1.1: Normalize and standardize the raw sensor data acquired by the sensor. The specific method is to use the Min-Max model for normalization, as shown in formula (1), and convert the normalized data to the mean value is 0 and a distribution with a standard deviation of 1;

[0076]

[0077] Data standardization, as shown in formula (2):

[0078]

[0079] In formula (1), (2), x' i,j (t) represents the dimensionless sample, x i,j (t) represents the original sample, max(x :,j ) represents the maximum value of the same dimension sample, min(x :,j ) represents the minimum value of the same dimension; represents the sample mean; s repr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com