RFID-based coupling capacitor element welding and mounting equipment

A technology for installing equipment and coupling capacitors, applied in the field of RFID applications, can solve problems such as reduced work efficiency, inaccurate positioning, and low work efficiency, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

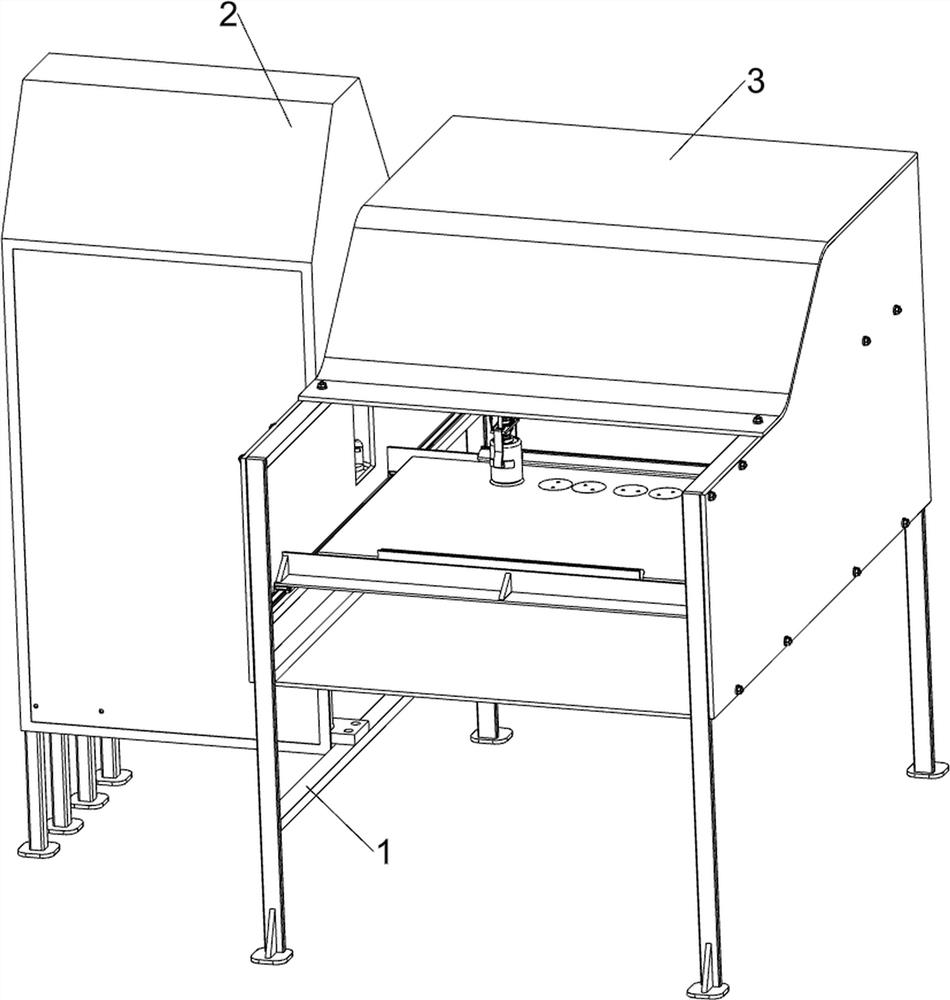

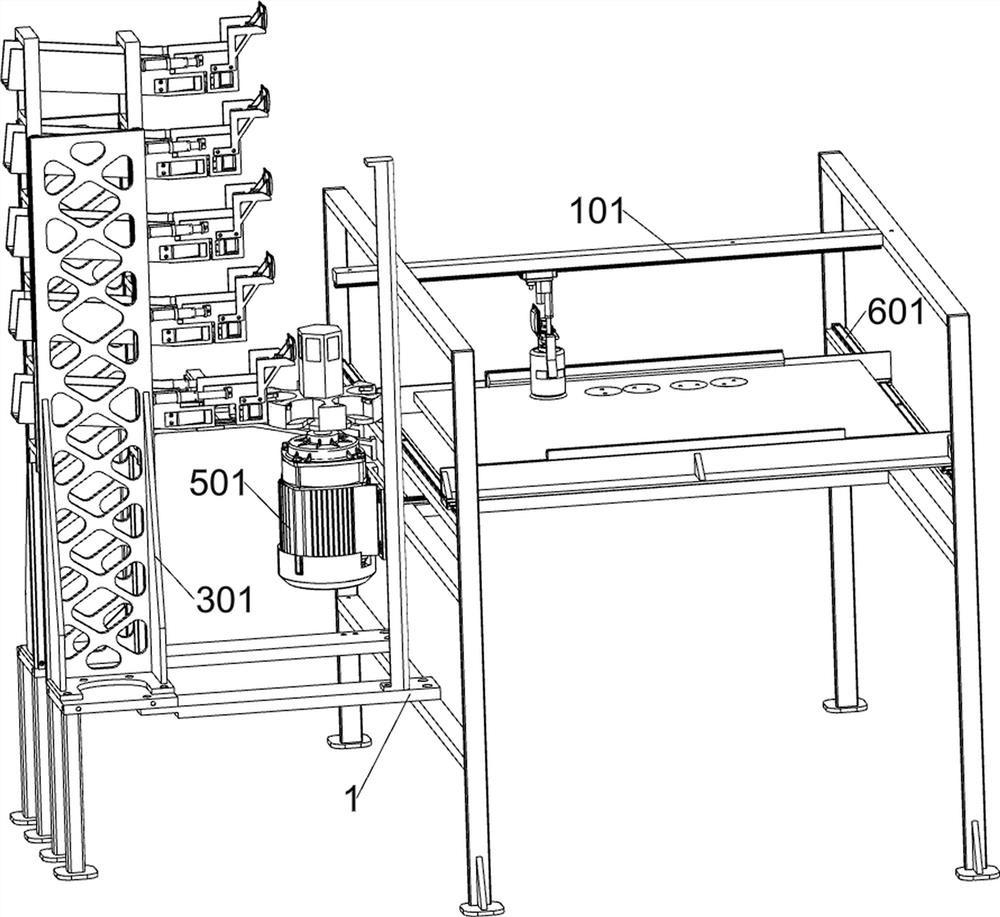

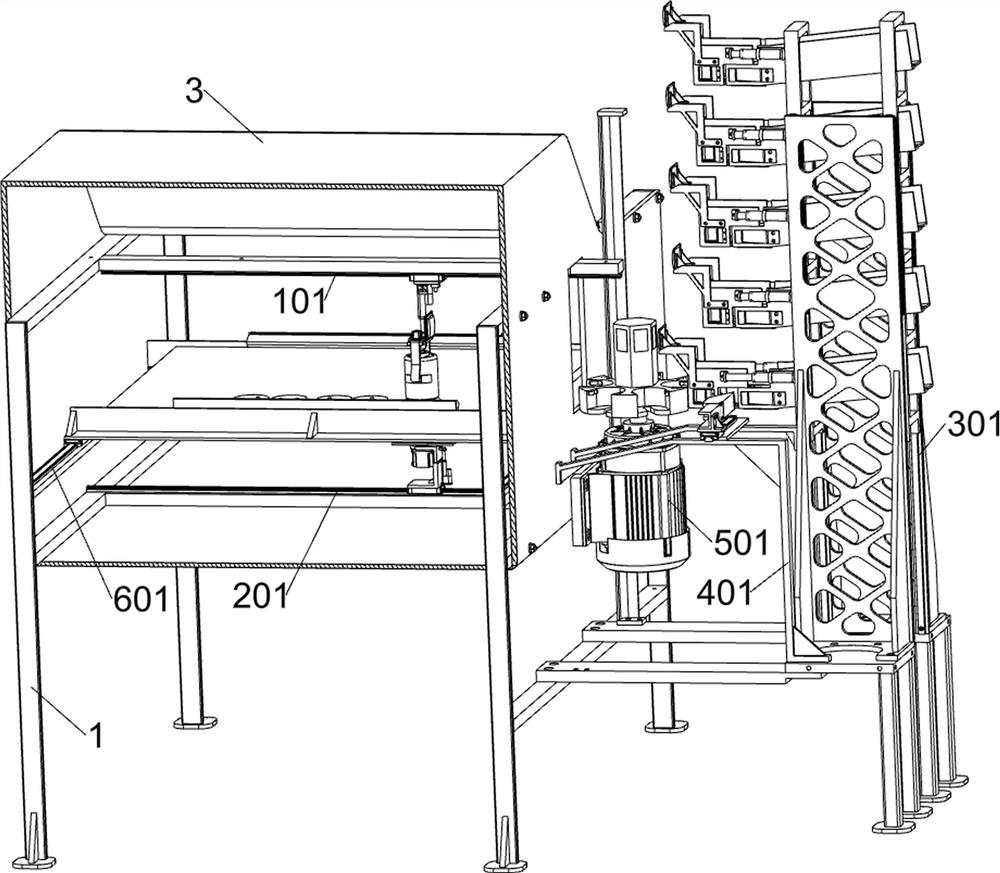

[0039] A kind of welding installation equipment based on RFID coupling capacitive components, such as Figure 1-19 As shown, it includes a frame 1, a feeding shell 2, a welding cover 3, a positioning installation component and a welding assembly; the feeding shell 2 is fixedly connected to the top left side of the frame 1; the welding cover 3 is fixedly connected to the top left side of the frame 1 ; The middle part of the right end of the feeding shell 2 is fixedly connected with the welding cover 3; the right side of the top of the frame 1 is connected with a positioning installation component;

[0040] Working principle: Before using the RFID-based coupling capacitor element welding installation equipment, first fix the RFID-based coupling capacitor element welding installation equipment to the position of use, and then manually place the corresponding type of coupling capacitor element on the positioning installation assembly, At the same time, the circuit board is manuall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com