Ultra-light high-resilience shoe sole and preparation method thereof

A high-resilience, ultra-light technology, applied in soles, footwear, footwear, etc., can solve the problems of increasing the weight of soles, easy to corrode soles, and difficult to achieve lightweight and high resilience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments according to the present invention will now be described in detail with reference to the accompanying drawings.

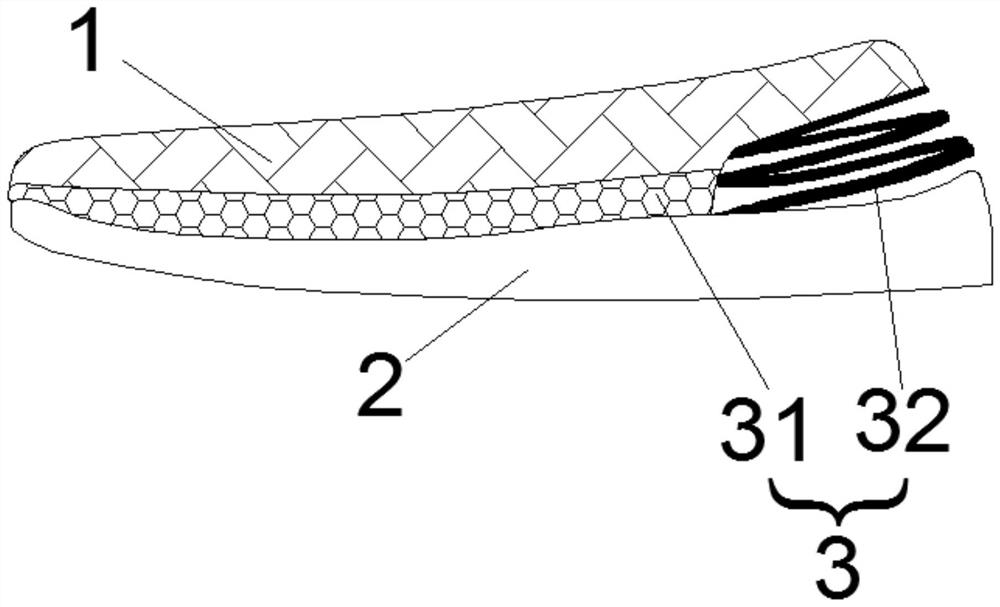

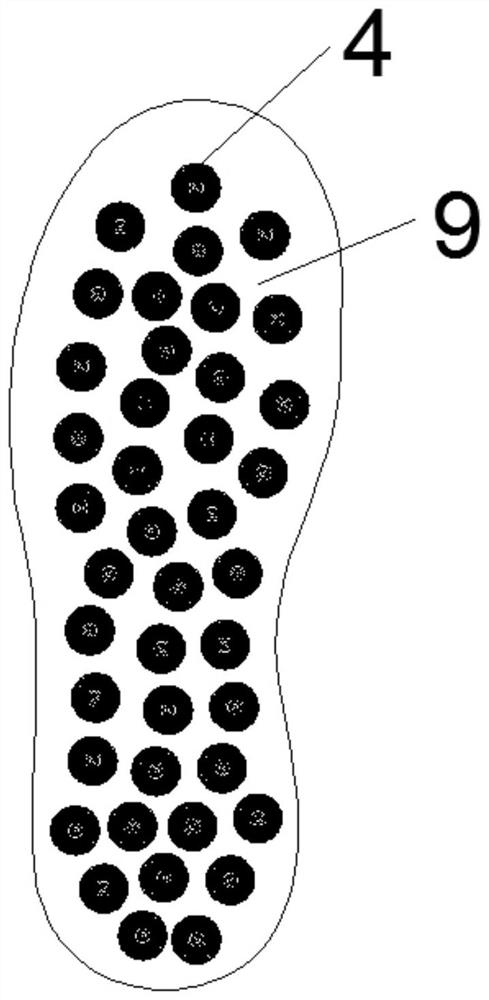

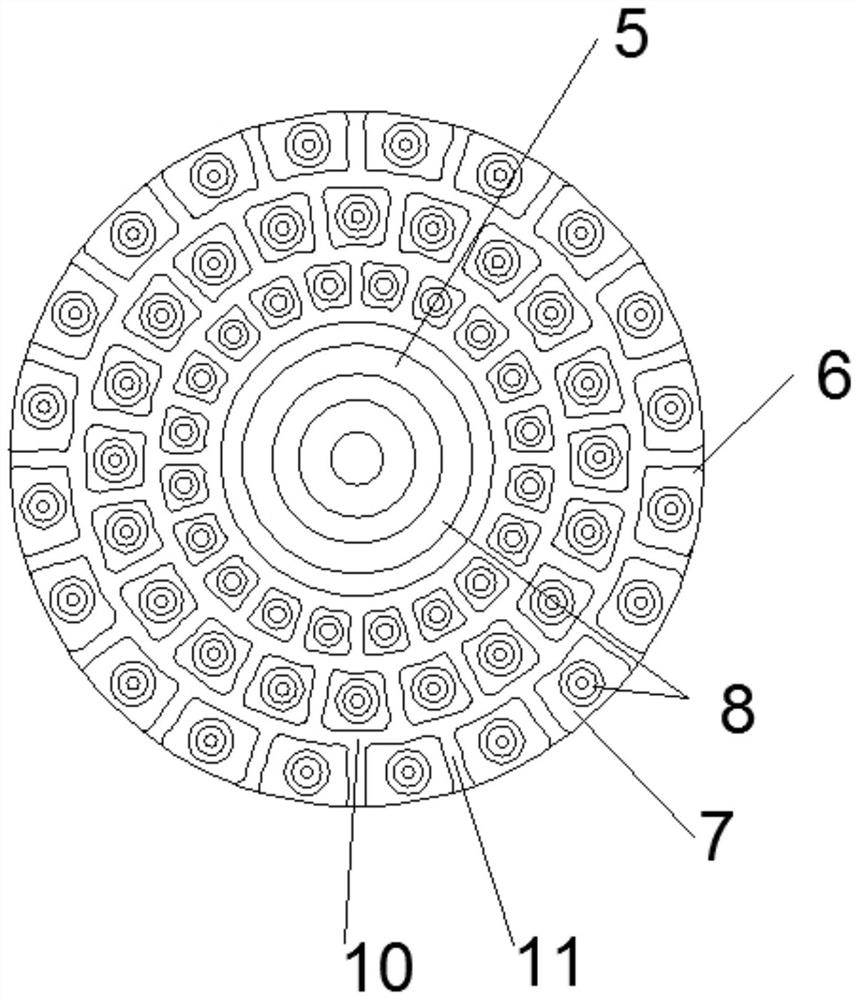

[0027] As a first aspect of the present invention, with reference to Figure 1-3 , according to an embodiment of the present invention, an ultra-light high-resilience shoe sole includes a midsole 2, an outsole 1, and a connection layer 3 connected between the outsole 1 and the midsole 2; the outsole 1 is evenly distributed with The anti-skid structure 4 of the outsole 1 is integrally formed. The connecting layer 3 includes a first elastic body 31 connected as a whole by a plurality of inflatable balloons and a second elastic body 32 folded into multiple layers arranged at the heel position. The elastic body 31 is connected to both sides of the second elastic body 32. The number of folded layers of the second elastic body 32 gradually increases from the side to the heel, and the thickness of each folded layer is from the outsole 1 to the midsole 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com