Implant with titanium plate retention structure, preparation method and application

An implant and retention technology, applied in the field of tooth restoration, can solve the problems of excessive alveolar bone absorption, long treatment process, inability to effectively prepare the initial stability of the implant socket, etc., to achieve the effect of expanding indications and increasing the treatment cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

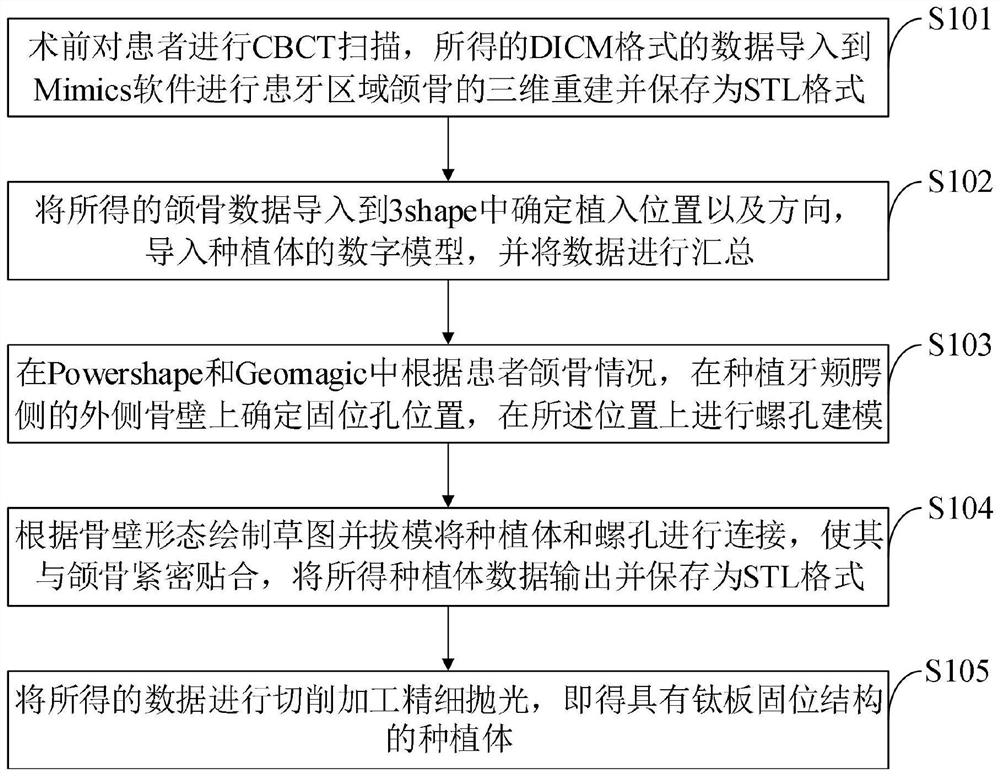

[0043] like figure 1 As shown, the preparation method of the implant with titanium plate retention structure provided by the embodiment of the present invention comprises the following steps:

[0044] S101, CBCT scanning is performed on the patient before operation, and the obtained data in DICM format is imported into Mimics software for three-dimensional reconstruction of the jawbone in the affected tooth area and saved in STL format;

[0045] S102, import the obtained jaw bone data into 3shape to determine the implant position and direction, import the digital model of the implant, and summarize the data;

[0046] S103, according to the condition of the patient's jaw in Powershape and Geomagic, determine the position of the retention hole on the outer bone wall of the buccal and palatal side of the implant, and perform screw hole modeling on the position;

[0047] S104, draw a sketch according to the shape of the bone wall and draw the mold to connect the implant with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com