Carbon dioxide waste gas pollution abatement purification tower convenient for cleaning particle impurities

A carbon dioxide and pollution control technology, applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of dust collection tank, poor purification effect, increased strength, etc., to ensure cleanliness and effect. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

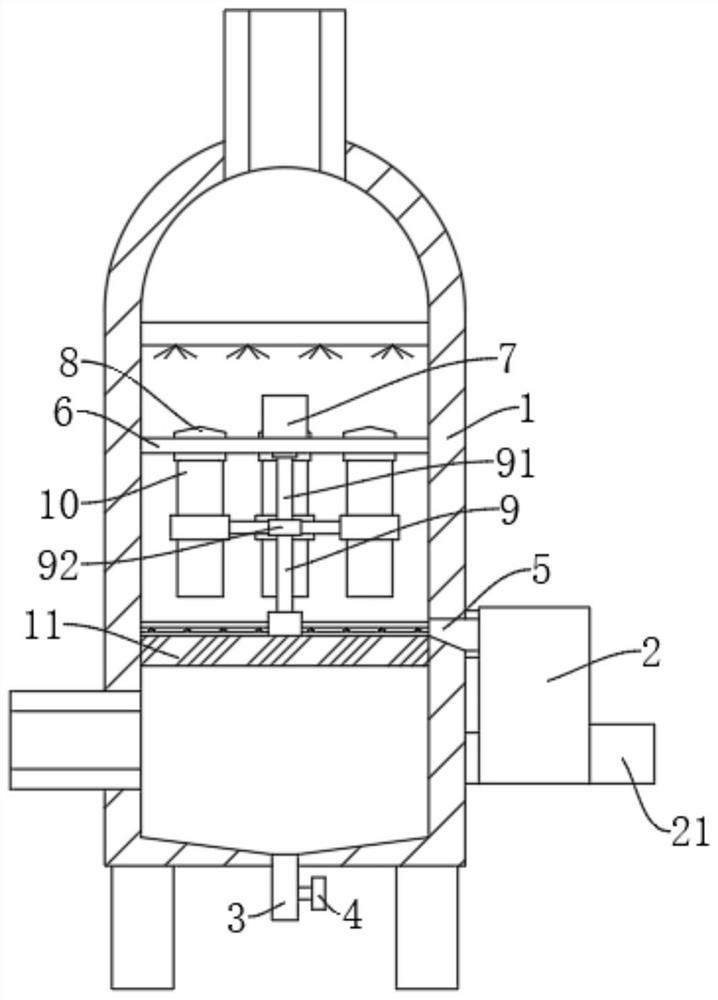

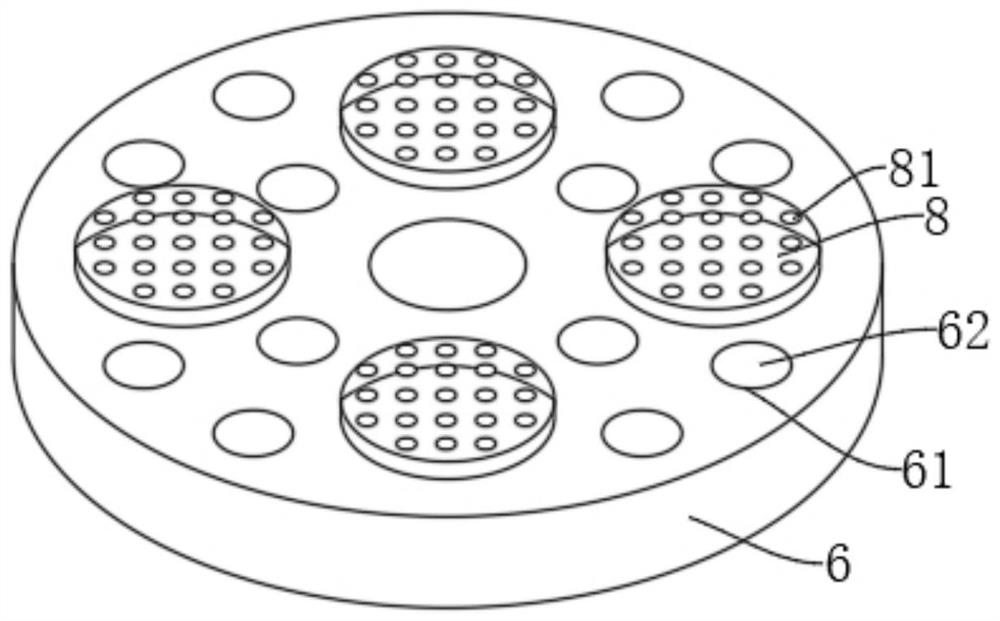

[0024] see Figure 1-2 , the present invention provides a technical solution: a carbon dioxide waste gas pollution treatment and purification tower that is convenient for cleaning particulate impurities, including a tower body 1, a filter plate 11 is fixedly connected to the inner wall of the lower section of the tower body 1, and the top of the filter plate 11 is in frictional contact with cleaning. Part 9, the top of the cleaning part 9 is fixedly connected with the output shaft of the waterproof motor 7, the waterproof motor 7 is coaxially fixed on the fixed plate 6, the fixed plate 6 is fixedly installed on the upper section inner wall of the tower body 1, and the fixed plate 6 runs through the set There are some drain holes 61, and the anti-reverse valve disc 62 is fixedly connected in the drain holes 61, and the center of the fixed plate 6 is provided with a through hole that rotates through the output shaft of the waterproof motor 7.

[0025] Such as figure 1 and fig...

Embodiment 2

[0027] refer to Figure 1-5 , is the second embodiment of the present invention, which is based on the previous embodiment, specifically,

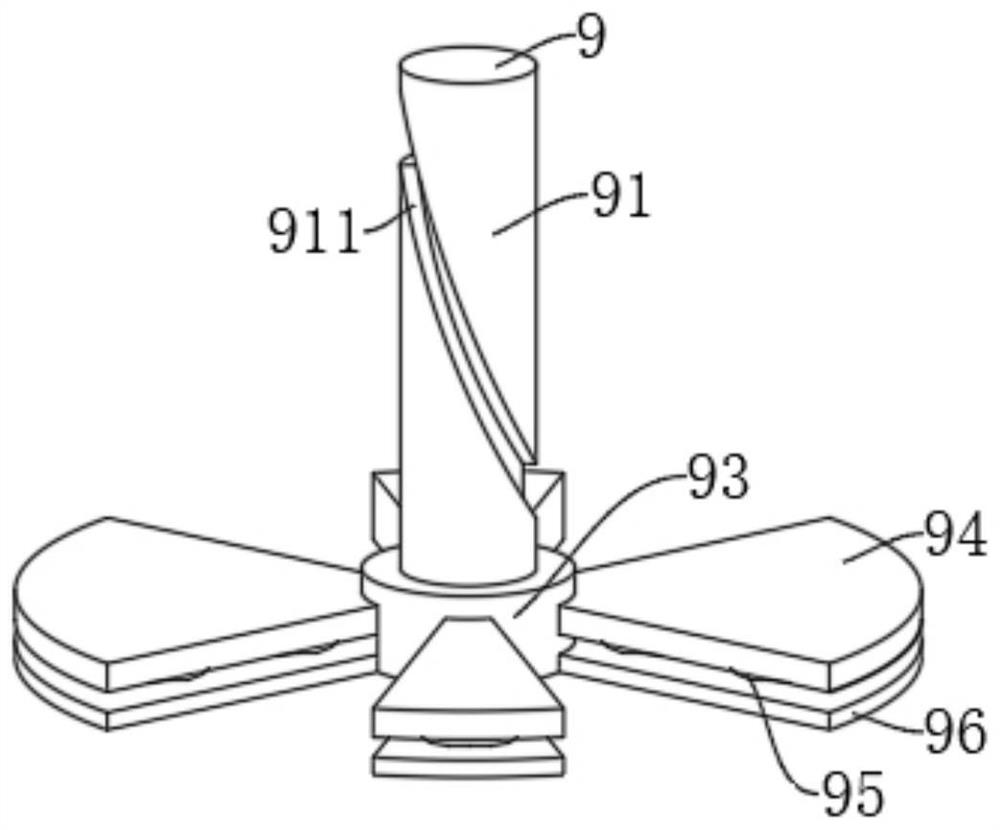

[0028] Such as Figure 1-4 As shown, the cleaning part 9 includes a transmission shaft 91, the top of the transmission shaft 91 is coaxially fixed on the output shaft of the waterproof motor 7, the transmission shaft 91 is slidably covered with a sliding cylinder 92, and the outer wall of the sliding cylinder 92 is fixedly connected with several connecting rods 97, the end of the connecting rod 97 away from the sliding cylinder 92 is fixedly connected with a collar 98, the inner wall of the collar 98 is fixedly connected with an annular brush 99, and the annular brush 99 frictionally contacts the outer wall of the filter core tube 10, and the bottom end of the transmission shaft 91 is coaxially fixed. Be connected with fixed column 93, and the outer wall of fixed column 93 is fixedly connected with some supporting plates 94, and the botto...

Embodiment 3

[0032] refer to Figure 1-5 , which is the third embodiment of the present invention. This embodiment is based on the above two embodiments. When in use, the carbon dioxide waste gas is input through the inlet pipe on the bottom side of the tower body 1. The carbon dioxide waste gas is first filtered and purified by the filter plate 11, and absorbed The large particulate matter in the gas passes through the filter plate 11 and is adsorbed and filtered by the filter core tube 10 to filter and purify the fine particles and harmful gases in the waste. The fine particles adhere to the outer wall of the filter core tube 10, and the purified waste passes through The top of the filter tube 10 passes through the threaded end cap 8, and then it is discharged through the exhaust hole 81 on the end cap 8. The discharged exhaust gas is neutralized under the spraying liquid of the spray head at the top, and then passes through the exhaust pipe at the top after neutralization. discharge; wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com