Rice polishing equipment

A kind of equipment and rice technology, which is applied in the direction of grain finishing, dust removal, grain processing, etc., can solve the problems of slow efficiency and damage to the integrity of rice, and achieve the effect of improving polishing efficiency and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

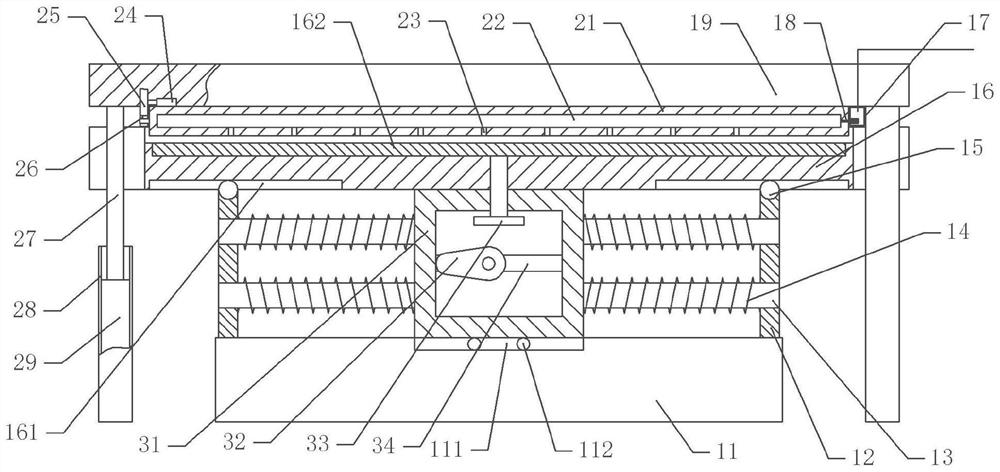

[0034] A kind of rice polishing equipment, as attached figure 1 As shown, it includes a base 11 and support plates 12 arranged on both sides of the base 11 , the support plate 12 is fixedly connected with the base 11 by bolts, and a swing mechanism is arranged between the two support plates 12 .

[0035] In this embodiment, the swing mechanism includes a swing box 31, the bottom of the swing box 31 is rotatably connected with a roller 112, the base 11 is provided with a chute 111, the roller 112 is located in the chute 111, and the swing box 31 passes through the chute 111 and the roller 112 Slidingly cooperate with the base 11 horizontally. Both sides of the swing box 31 are bolt-fixed with a guide shaft 13, the guide shaft 13 is horizontally slidably connected with the support plate 12 and the guide shaft 13 runs through the support plate 12, the guide shaft 13 is sleeved with an elastic member, the elastic member is a spring 14, the spring One end of 14 is welded and fixed...

Embodiment 2

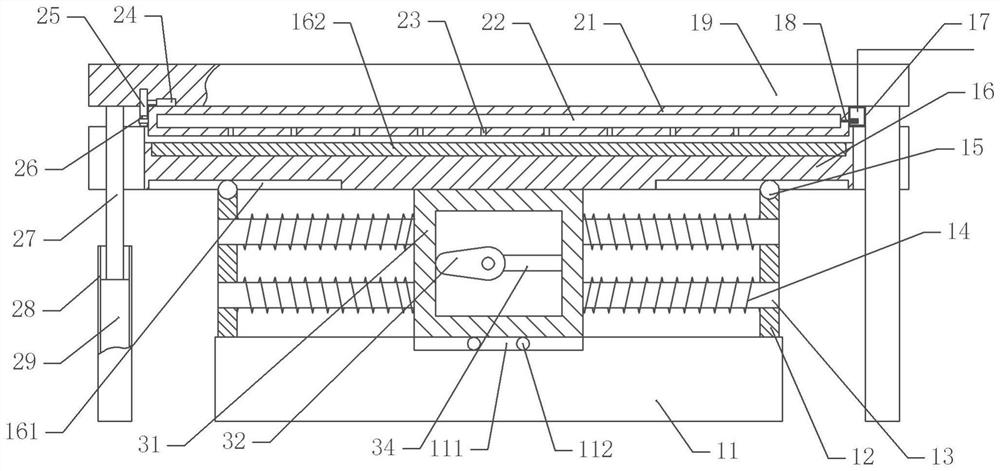

[0046] The difference between embodiment two and embodiment one is that, as attached figure 2 As shown, vertically slidingly connected with a push shaft 33 in the swing box 31, the push shaft 33 is vertically slidably connected with the lower polishing plate 16, and vertically slidably connected with a vibrating plate 162 in the polishing tank, and the vibrating plate 162 is offset against the pushing shaft 33.

[0047] In this embodiment, when the cam 32 rotates, the cam 32 will be against the push shaft 33, so that the push shaft 33 moves upward. When the push shaft 33 moves upward, the vibrating plate 162 and the rice are pushed to slide upward. The cam 32 and the push shaft 33 When disengaging, the vibrating plate 162 and the pushing shaft 33 will move downward under the action of gravity, and the pushing plate will drive the rice to move downward, so that the rice will vibrate so that the rice will be turned over as far as possible, then through the method of embodiment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com