Grease injection equipment for rubber bushing

A rubber bushing and equipment technology, applied in the field of auto parts processing equipment, can solve the problems of increasing manufacturing costs, wasting manpower, and low efficiency, and achieve the effects of improving production efficiency, realizing semi-automation, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

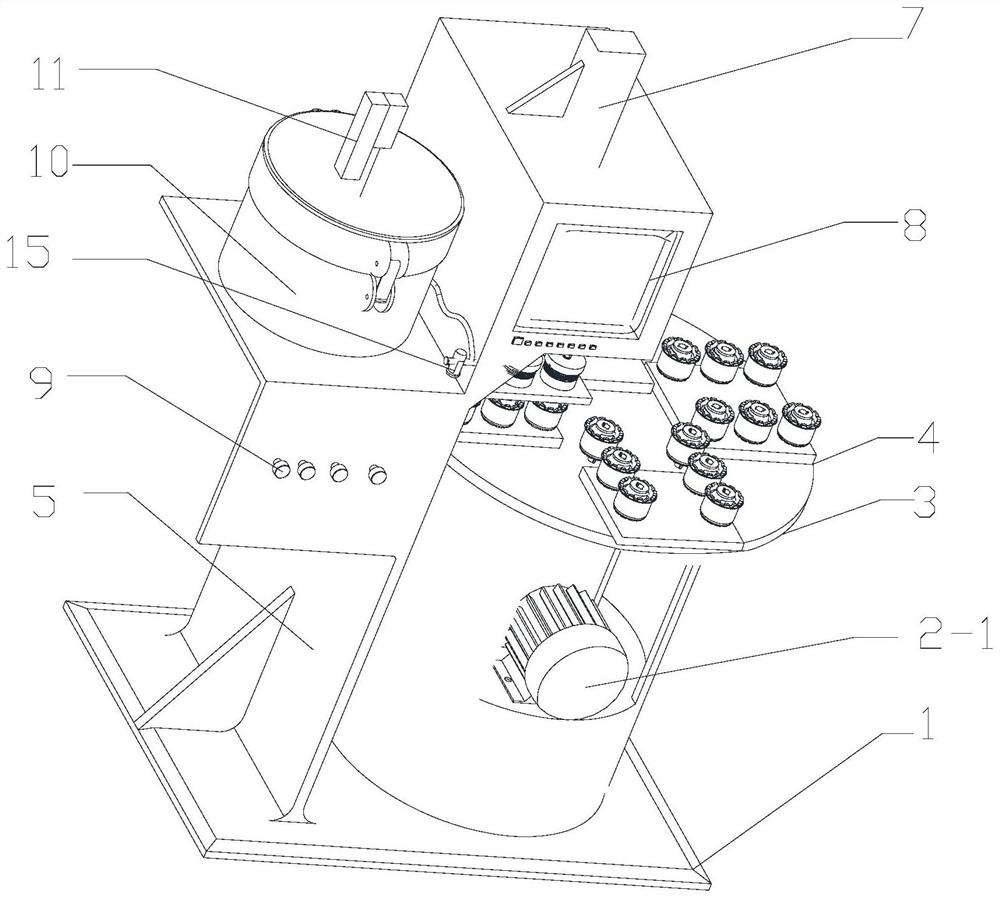

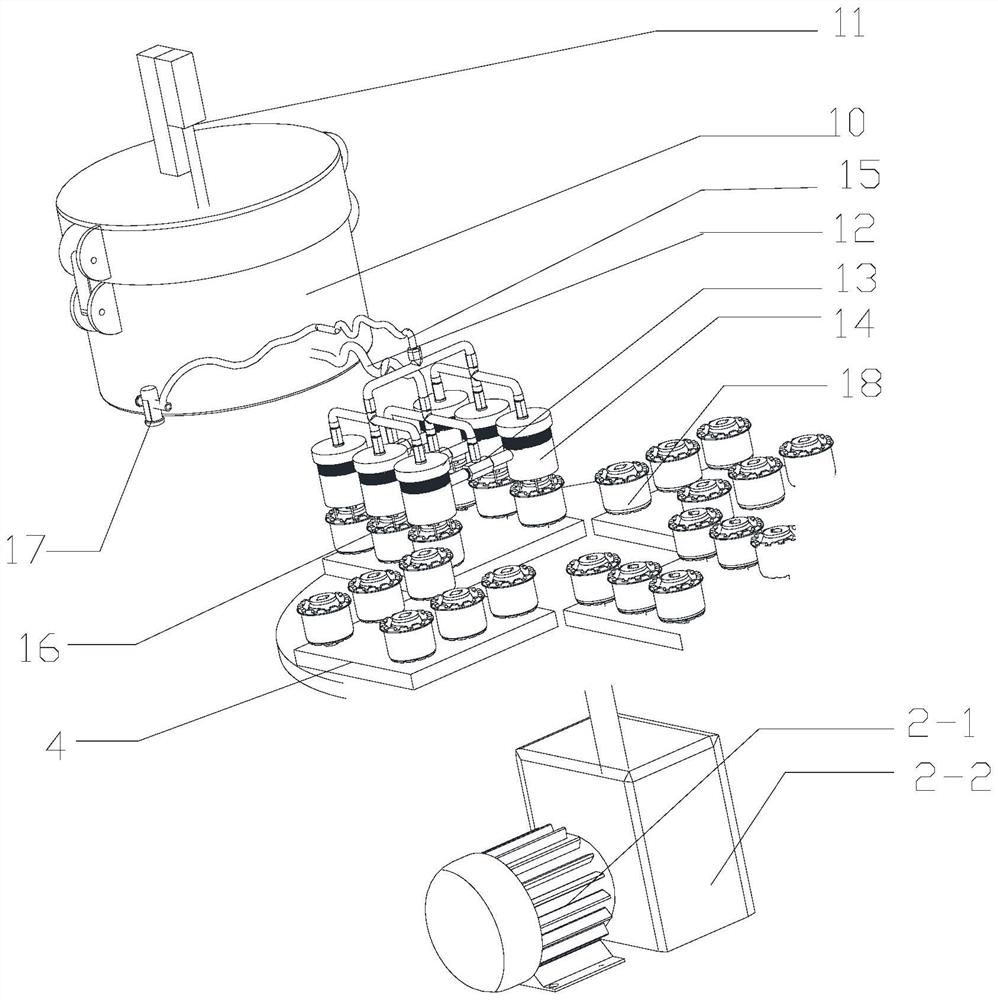

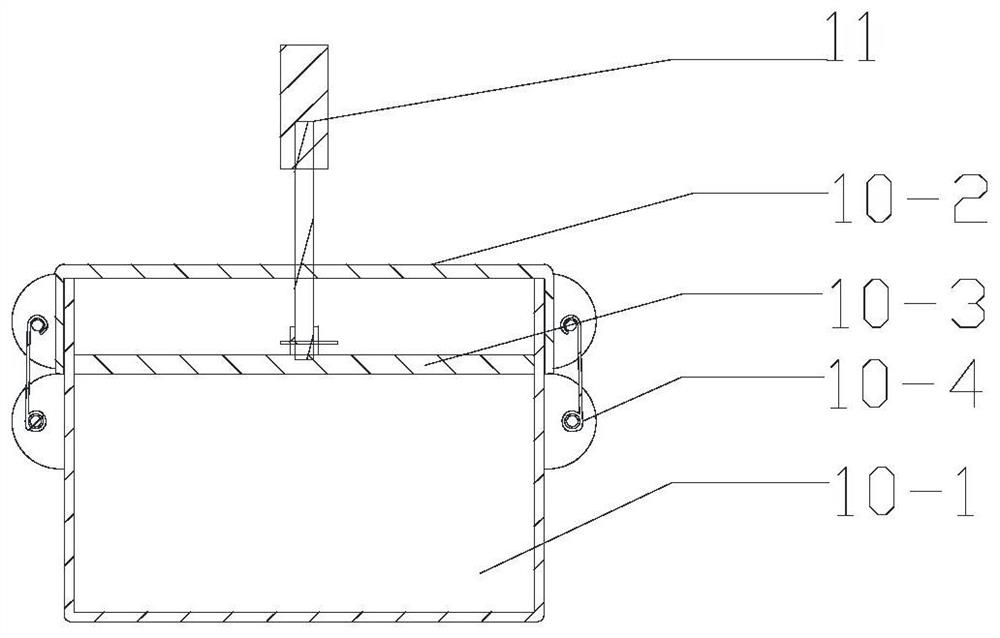

[0021] The invention provides a rubber bushing grease injection device, which is used when injecting grease into rubber bushes of automobiles, such as figure 1 , Figure 5 As shown, it includes equipment base 1, turntable motor 2-1, motor reducer 2-2, turntable 3, fixture 4, mounting frame 5, lifting track 6, lifting motor 7, parameter adjustment screen 8, equipment operation switch 9, Butter storage tank 10, gas compression pump 11, butter delivery pipeline 12, delivery pipeline tap 13, equipment oil storage tank 14, air pipe 15, injection head 16, air pressure regulating valve 17, oil injection bushing 18.

[0022] The turntable motor 2-1 is connected to the turntable 3 through the motor reducer 2-2. The turntable 3 is provided with a plurality of clamps 4, and each clamp 4 is provided with a plurality of placement positions fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com