Garbage crushing and drying device suitable for garbage incineration power generation project

A garbage crushing and garbage incineration technology, applied in the direction of drying gas arrangement, drying solid materials, non-progressive dryers, etc., can solve the problems of inability to pile up garbage, poor work continuity, and difficult transportation of garbage, etc., to achieve good incineration work, Improve work efficiency, facilitate transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

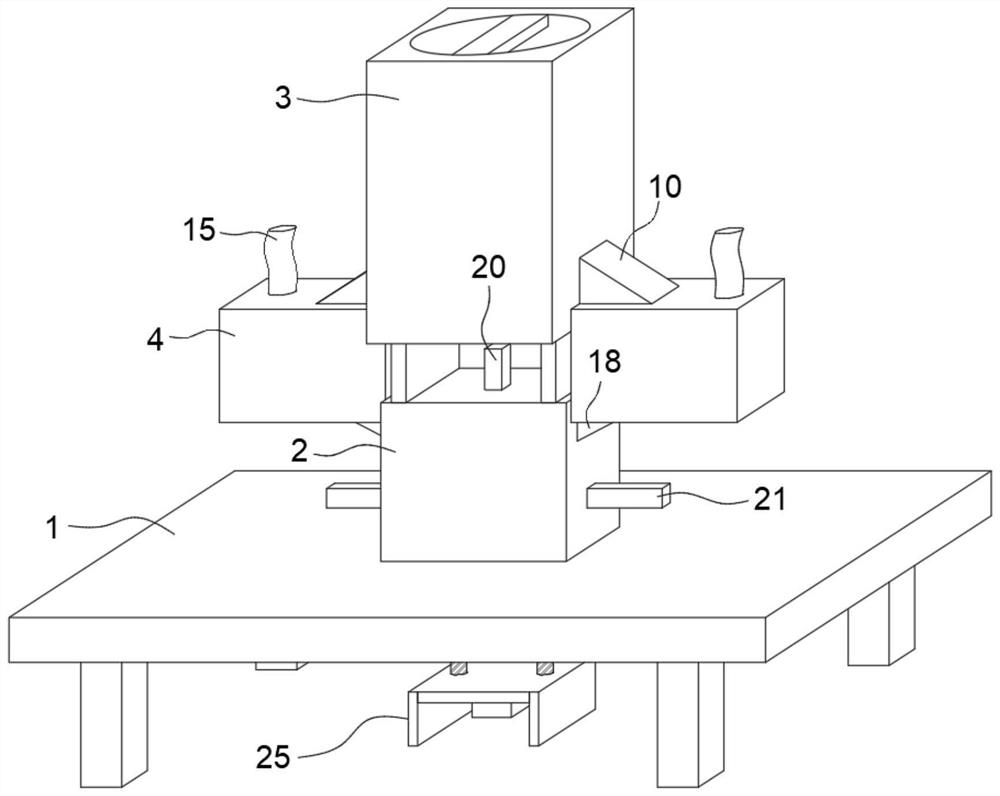

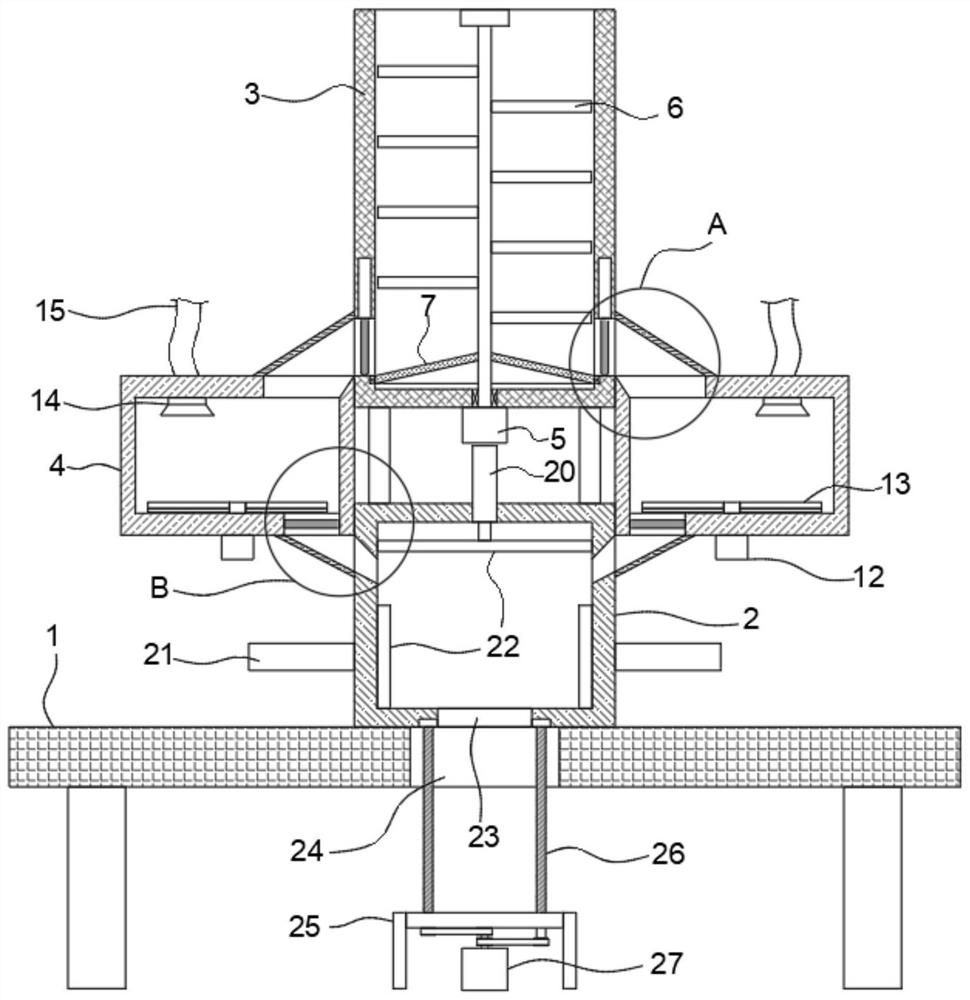

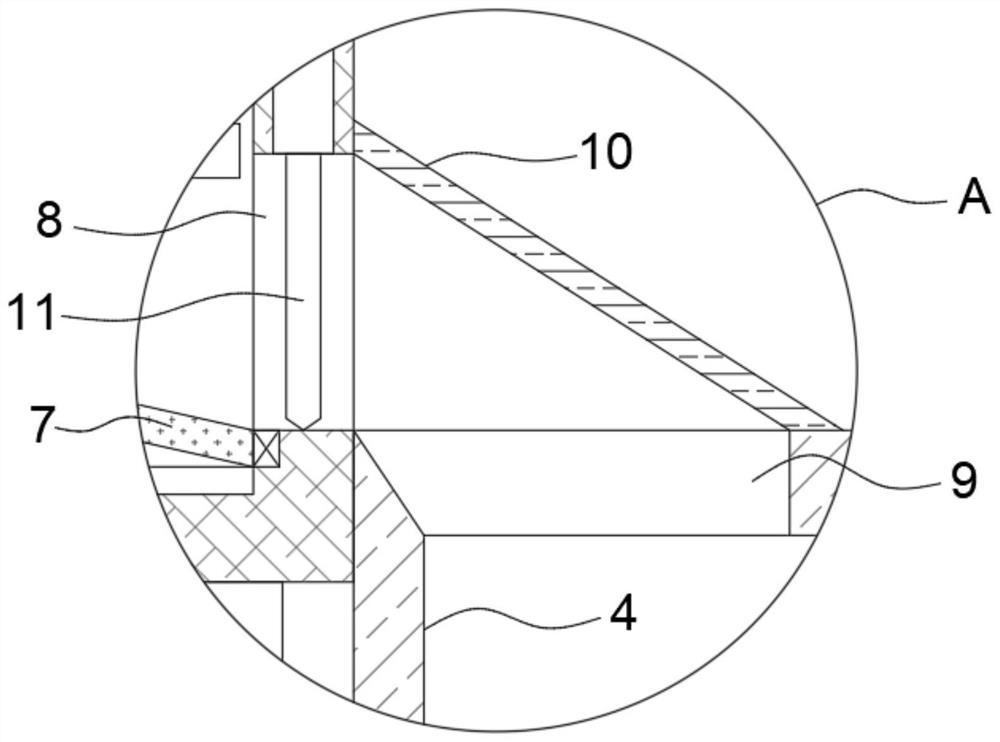

[0027] refer to Figure 1-5 , a waste crushing and drying device suitable for waste incineration power generation projects, comprising a device table 1, a squeeze box 2 is fixedly connected to the upper end of the device table 1, a crush box 3 is arranged above the squeeze box 2, and the crush box 3 and the squeeze box 2 are jointly fixedly connected with two vertical plates for fixing the crushing box 3, and both sides of the crushing box 3 and the extrusion box 2 are jointly fixedly connected with a drying box 4, and a cylindrical crushing box 3 is provided inside the crushing box 3. The upper end of the crushing chamber is provided with an opening, which is convenient for putting crushed and dried garbage into the crushing chamber. The center of the lower end of the crushing box 3 is fixedly installed with a first motor 5, and the output end of the first motor 5 is fixedly connected with a rotating rod. The rotating rod runs through the bottom wall of the crushing chamber a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com