Efficient ball mill for powder metallurgy

A technology of powder metallurgy and ball mill, which is applied in the field of powder metallurgy, can solve the problems of low grinding efficiency, falling or rolling off the inner wall of the cylinder, and difficulty in further improving the fineness of the output, so as to improve the grinding efficiency and the fineness of the output. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

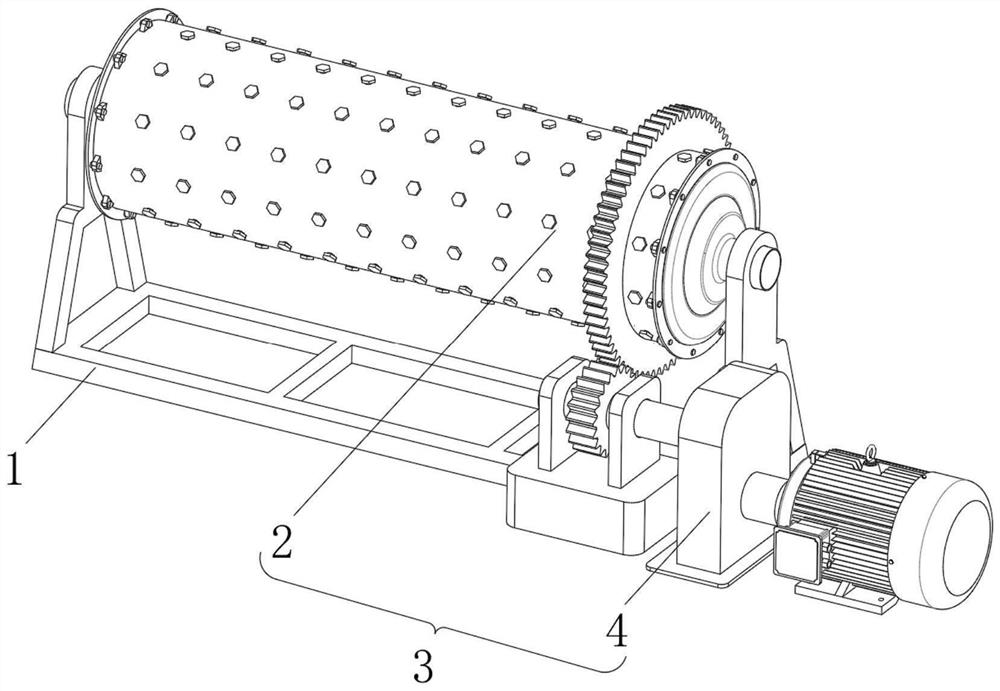

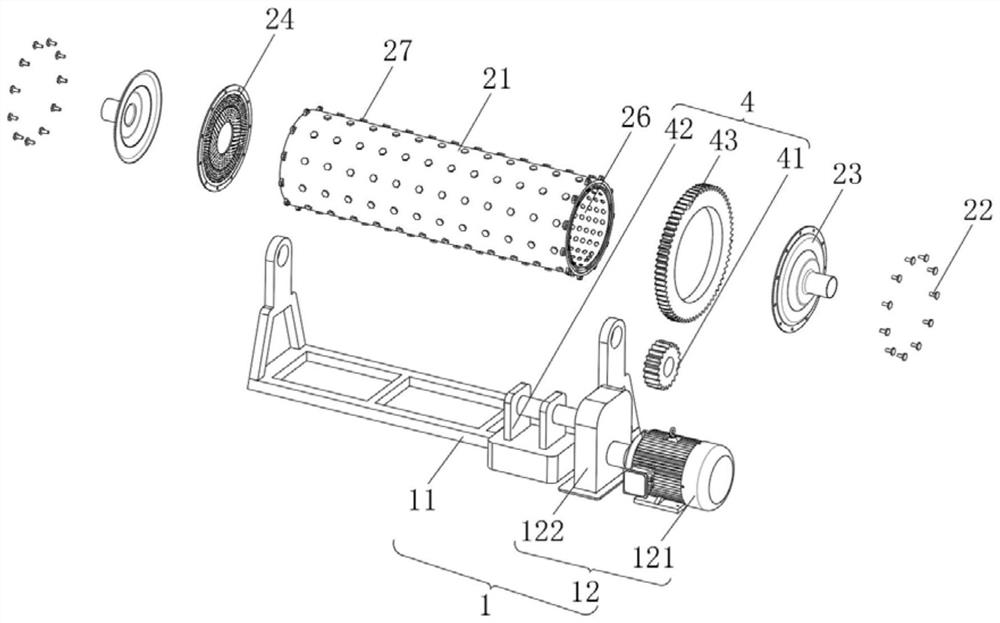

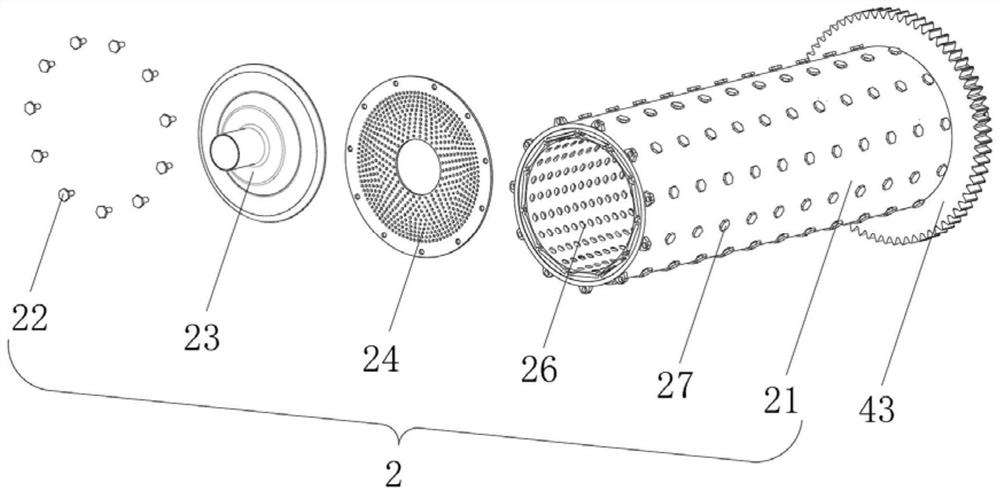

[0040] see Figure 1-9 , the present invention provides a technical solution: a high-efficiency ball mill for powder metallurgy, comprising:

[0041] An operating body 1, the operating body 1 includes a connecting support 11, and a drive assembly 12 arranged outside the connecting support 11;

[0042] The ball mill assembly 3 arranged inside the connection support 11, the ball mill assembly 3 includes:

[0043]The barrel mechanism 2 is arranged inside the connecting support 11 and is used for crushing and grinding materials;

[0044] The transmission mechanism 4 connected with the barrel mechanism 2, the transmission mechanism 4 is used to drive the rotation direction of the barrel mechanism 2.

[0045] The driving assembly 12 includes a driving motor 121, and the drive motor 121 is connected with a reducer 122 on the outer side. The transmission mechanism 4 includes a pinion 41, and the pinion 41 is rotated on the outer side. , the inside of the reducer 122 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com