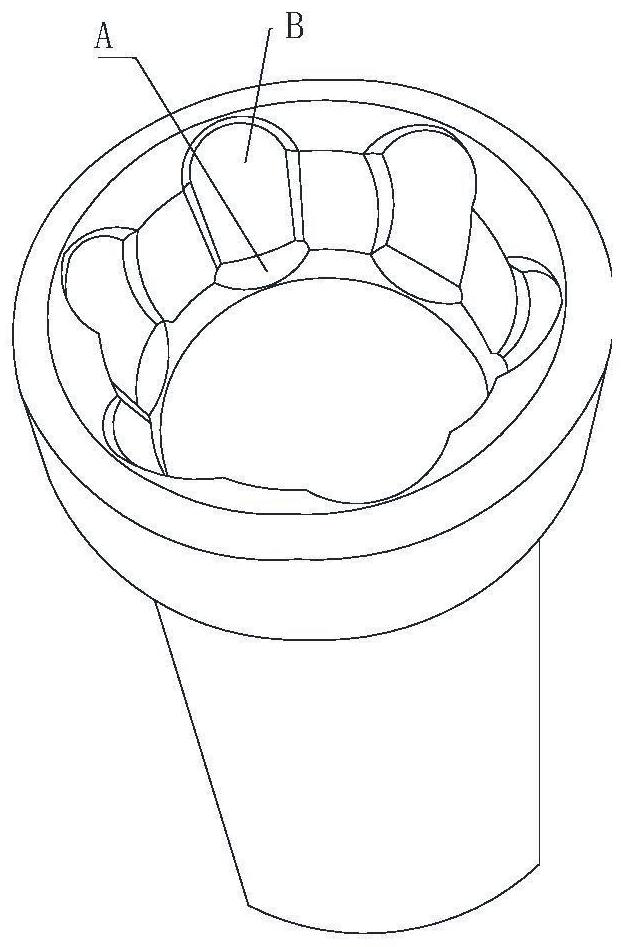

Special high-precision arc channel composite milling machine for bell housing

A high-precision, bell-shaped shell technology, applied in the field of milling machines, can solve problems such as laborious work, affecting machining accuracy, affecting product accuracy, etc., and achieves the effect of good motion stability, arc accuracy, and work stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

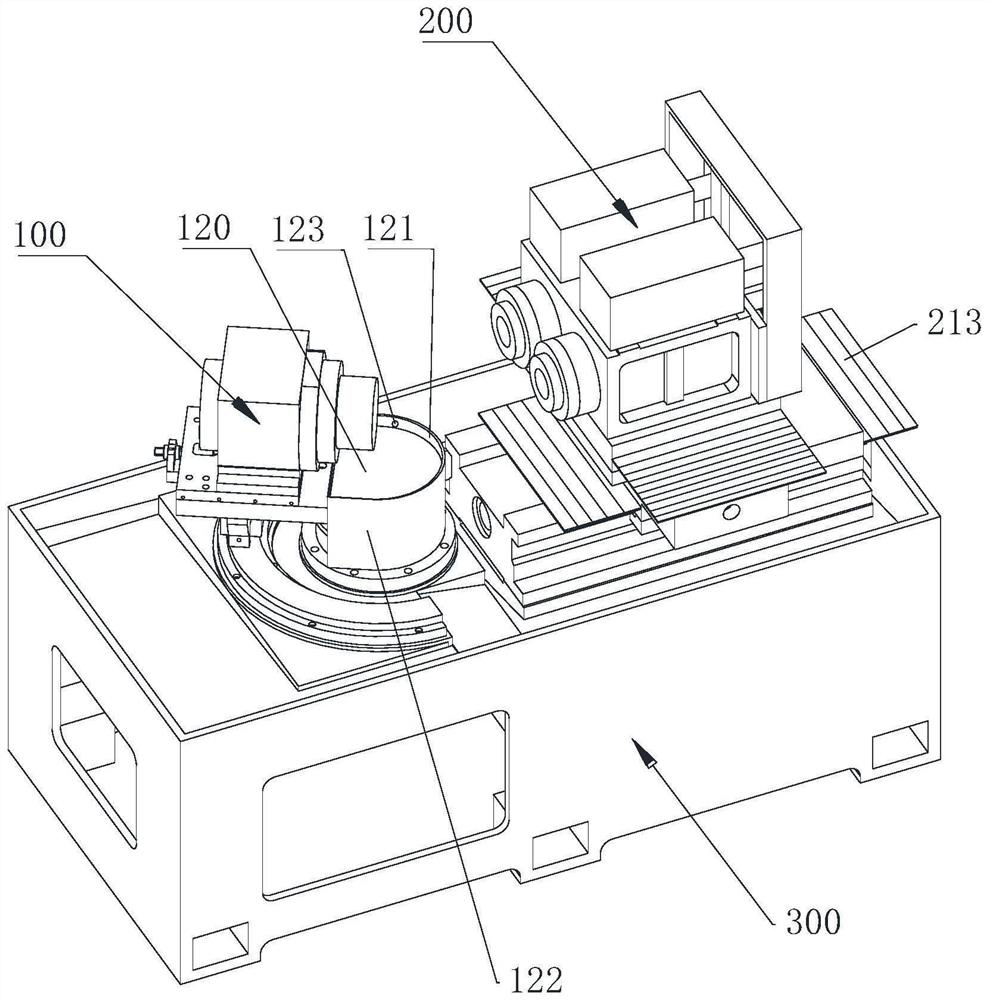

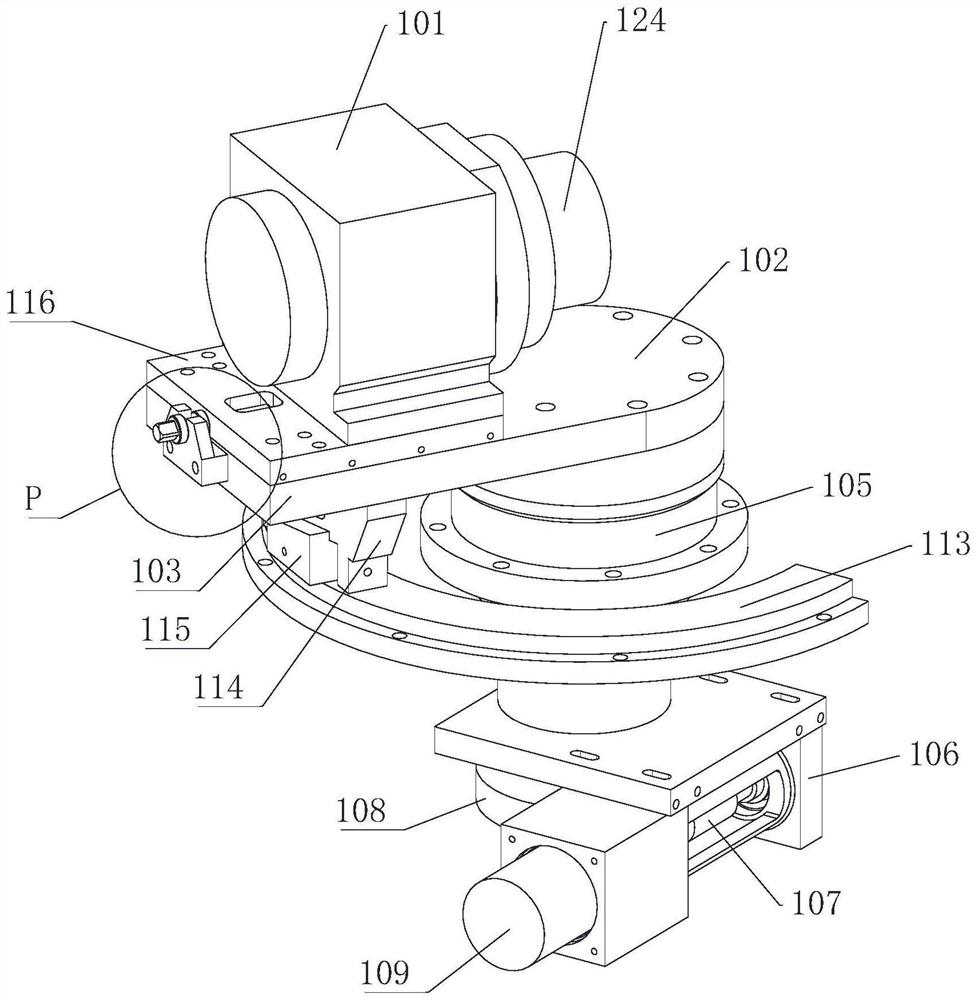

[0027] A high-precision arc groove compound milling machine dedicated to bell-shaped shells, refer to figure 2 , image 3 , Figure 5 and Figure 6 As shown, a high-precision arc groove compound milling machine dedicated to bell-shaped shells of the present invention includes a workbench 300 on which a clamping device 100 and a cutting device 200 are arranged. The clamping device 100 includes a collet 124 , hydraulic indexing turret 101, extension seat 103, turret seat 102, transmission rod 104, arc rotary table 105 and drive mechanism, the circular arc rotary table 105 is fixedly installed on the workbench 300, and the transmission rod 104 is installed on the circular In the arc rotary table 105, the turret base 102 is fixedly installed on the upper end of the transmission rod 104, the extension base 103 is integrally formed on one side of the turret base 102, and the hydraulic indexing turret 101 is fixedly installed on the extension base 103. The indexing turret 101 its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com