Device for laser cutting of low-temperature co-fired ceramic

A technology of low-temperature co-fired ceramics and laser cutting, applied in auxiliary devices, laser welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low-temperature co-fired ceramic plate bursting, reduced processing efficiency, and low practicability, and achieves guarantee Stable progress, improved processing efficiency, and high practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

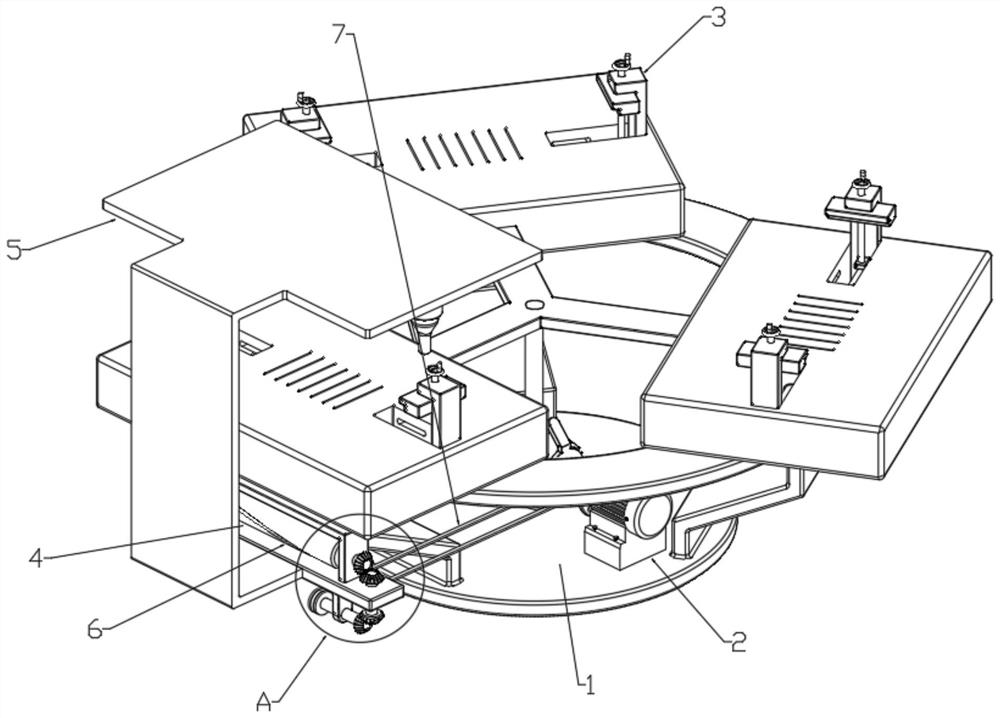

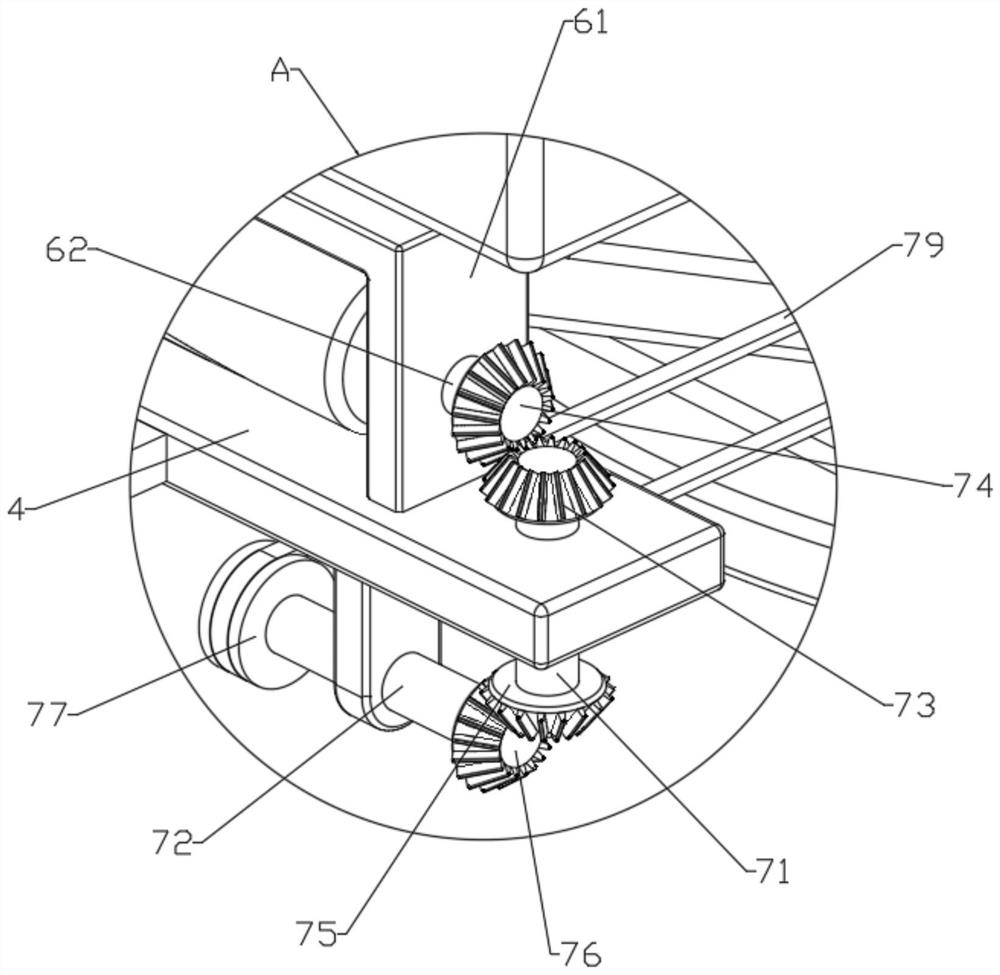

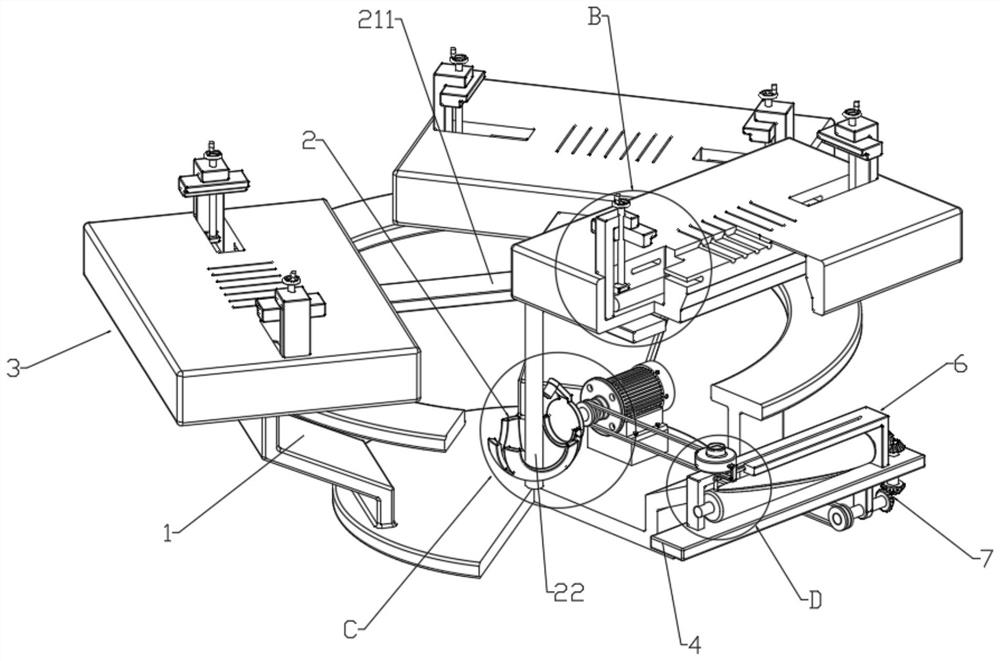

[0031] Example: such as Figure 1-8 As shown, the present invention provides a device for laser cutting low-temperature co-fired ceramics, including a mounting frame 1, an intermittent driving mechanism 2 is provided on the inner side of the mounting frame 1, and the top end of the intermittent driving mechanism 2 is fixedly connected with a Clamping mechanism 3 distributed in an array, T-shaped plate 4 is fixedly connected to the mounting frame 1, and a laser cutting mechanism 5 used in conjunction with the clamping mechanism 3 is fixedly installed on one side of the T-shaped plate 4. The laser cutting mechanism 5 It is possible to cut any shape of the low temperature co-fired ceramic plate, which is the prior art, and will not be repeated here, and the T-shaped plate 4 is provided with a heat dissipation mechanism 6 used in conjunction with the laser cutting mechanism 5, said One end of the T-shaped plate 4 is provided with a connection mechanism 7 used in conjunction with t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap