Fillet welding machine

A fillet knife and welding machine technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of poor surface finish, inaccurate positioning of feeding materials, limited space for blade grooves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

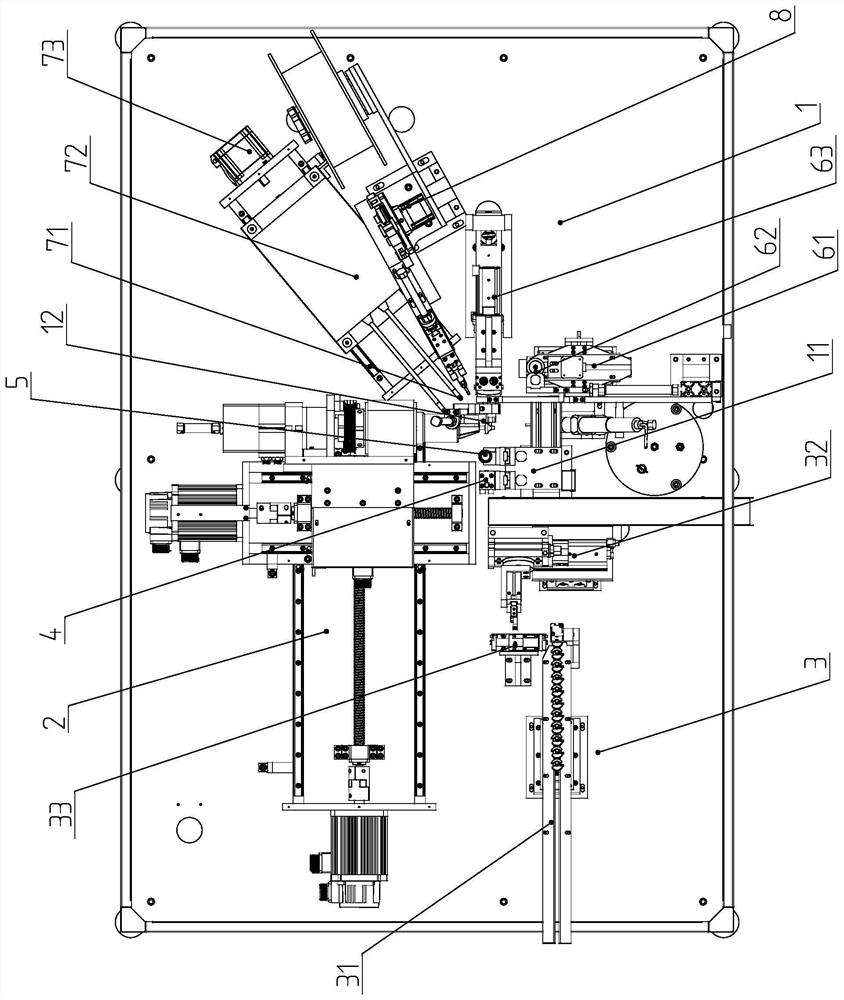

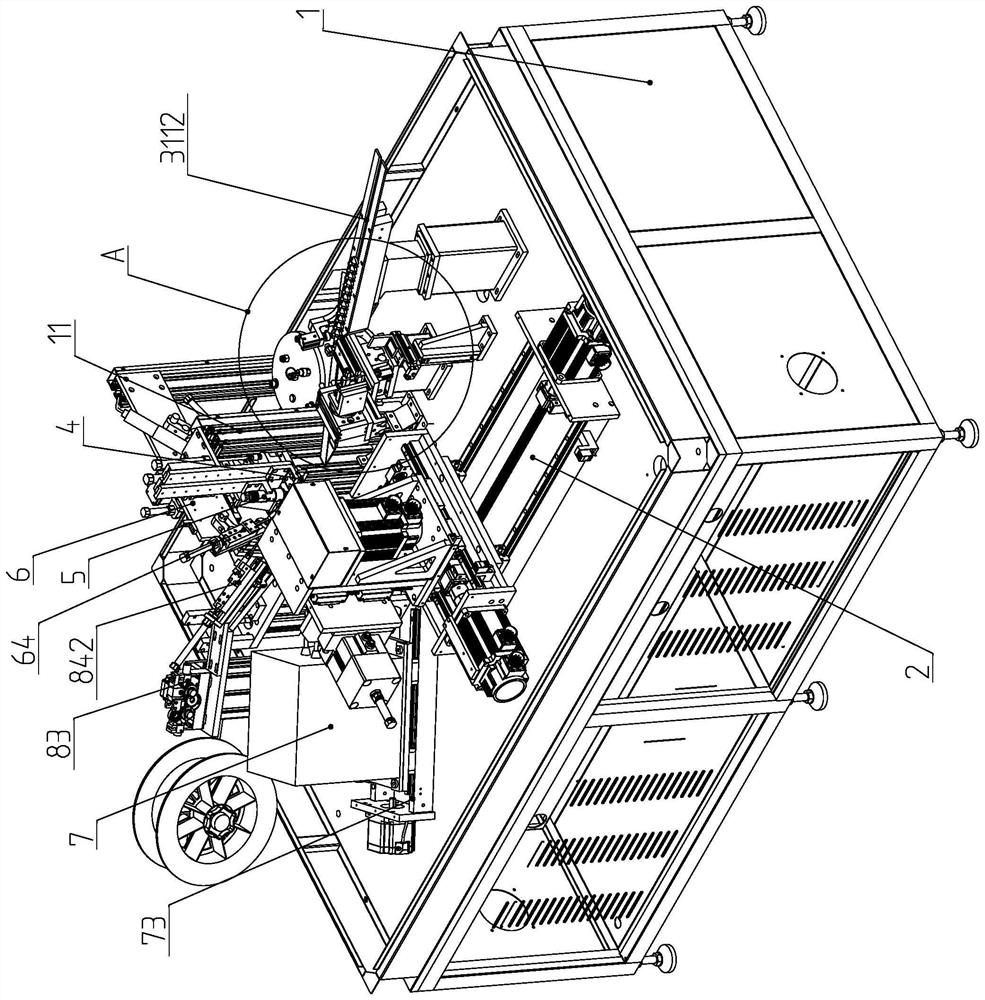

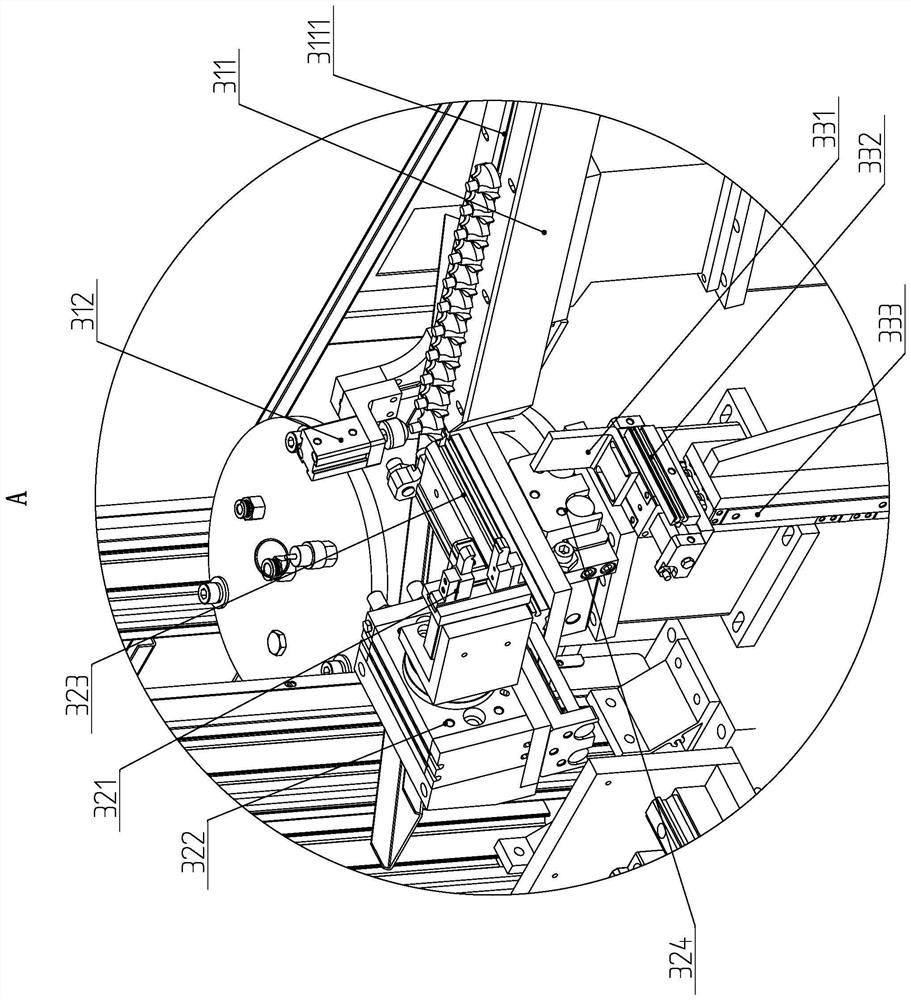

[0035] See attached Figure 1-8 , a fillet knife welding machine disclosed in this embodiment includes a machine platform 1, and the machine platform 1 is provided with a material transfer device 2 for controlling the movement of the fillet knife workpiece, and the material transfer device 2 includes a fixed The shell 21 of the fillet cutter workpiece and the three-axis moving mechanism 22 used to control the movement of the shell 21, the shell 21 is arranged on the three-axis moving mechanism 22, and one end of the shell 21 is provided with a The fastening mechanism 211 of the corner knife workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com