Grabbing, loading and unloading mechanism for industrial robot and using method of grabbing, loading and unloading mechanism

A technology of industrial robots and loading and unloading mechanisms, which is applied in the field of robots, can solve problems such as items slipping, and achieve the effect of avoiding loosening and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

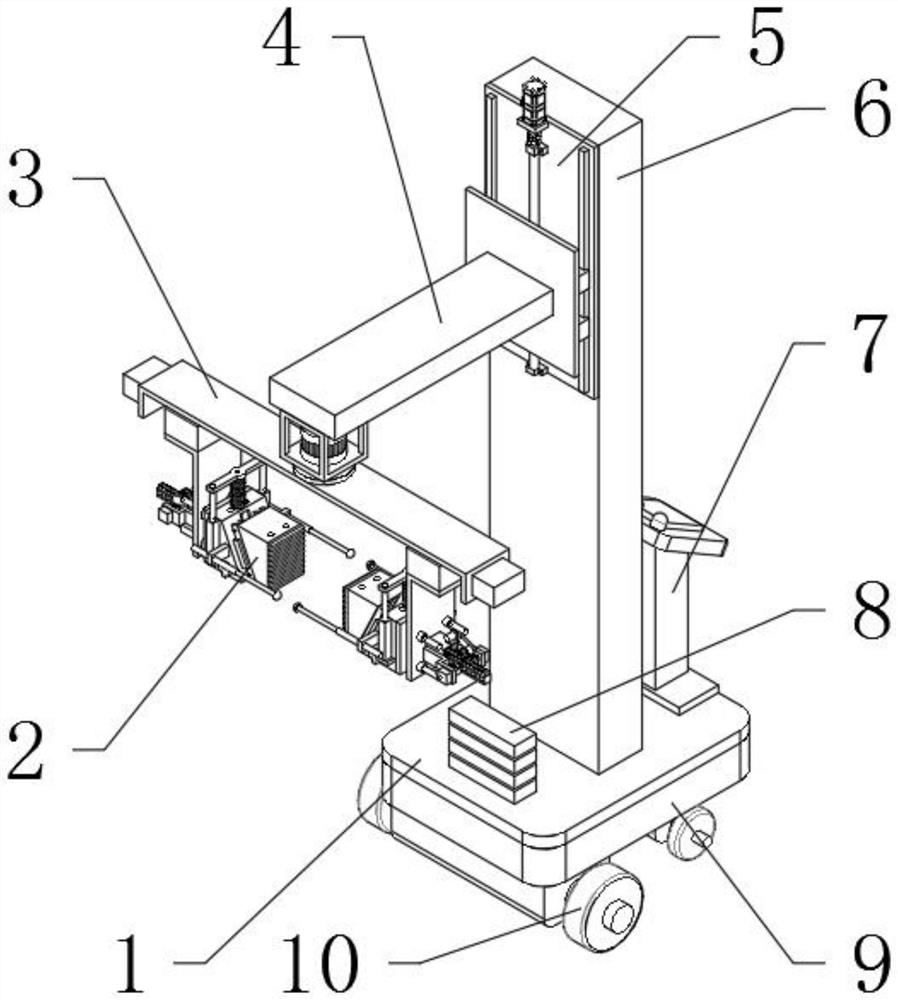

[0061] A grabbing and unloading mechanism for industrial robots, such as Figure 1-8 As shown, it includes a bottom plate 1 and two clamping arm mechanisms 2. The clamping arm mechanism 2 includes a fixed block assembly, an engaging assembly and a moving block assembly. The moving block assembly includes a wedge 14 and a friction plate 15. One side of the friction plate 15 The outer wall is fixedly connected to the outer wall on one side of wedge block 14, and the outer wall on one side of friction plate 15 is provided with sawtooth. The fixed block assembly includes wedge block two 21 and horizontal plate 11, and the top and bottom inner walls of wedge block two 21 are fixedly connected with inner shaft one 23 , inner shaft one 23 outer wall slidingly connected with lock block one 24, wedge one 14 top and bottom inner wall fixedly connected with inner shaft two 26, inner shaft two 26 outer wall slidingly connected with lock block two 27, wedge two 21 sides outer walls The cyl...

Embodiment 2

[0066] A grabbing and unloading mechanism for industrial robots, such as Figure 9 , Figure 10 As shown, in order to prevent the articles from falling out, a one-way locking mechanism is provided in the wedge two 21, and the one-way locking mechanism includes:

[0067] Guide bracket one 53, guide bracket one 53 is fixed on the inner wall of one side of wedge block two 21;

[0068] Movable rod one 46, movable rod one 46 is slidably connected to the inner wall of guide bracket one 53, one end of movable rod one 46 is integrally provided with extruding block one 50, and movable rod one 46 outer wall is integrally provided with convex plate one 51, convex plate one Between 51 and the guide bracket 1 53, the same convex plate spring 1 52 is fixed;

[0069] Weight-increasing block one 54, weight-increasing block one 54 is fixed on the bottom end of movable rod one 46;

[0070] Guide bracket two 48, guide bracket two 48 is fixed on the inner wall of wedge two 21 sides;

[0071] ...

Embodiment 3

[0075] A grabbing and unloading mechanism for industrial robots, such as Figure 10 , Figure 11 As shown, in order to prevent items from coming out, the one-way locking mechanism includes:

[0076] Guide bracket three 60, the guide bracket three 60 is fixed on the inner wall of one side of wedge two 21;

[0077] Movable rod 3 61, movable rod 3 61 is slidably connected to the inner wall of guide bracket 3 60, and the side wall of movable rod 3 61 is fixed with convex plate 2 58, and the same convex plate spring 2 is fixed between convex plate 2 58 and guide bracket 3 60 59, the two ends of the movable rod three 61 are fixed with a weight-increasing block two 62;

[0078] Sliding rheostat, the sliding rheostat is installed on the inner wall of the side of the wedge block 21, the sliding rheostat includes a sliding rheostat main body 63 and a sliding piece 64 used in conjunction with the sliding rheostat main body 63, the sliding piece 64 is fixed to the movable rod 3 61 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com