Double-station double-sucker feeding machine

A dual-station, sucker mechanism technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity, large errors, and poor coordination of subsequent processes in manual feeding, so as to shorten the loading time. The effect of reducing the material cycle, improving production efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

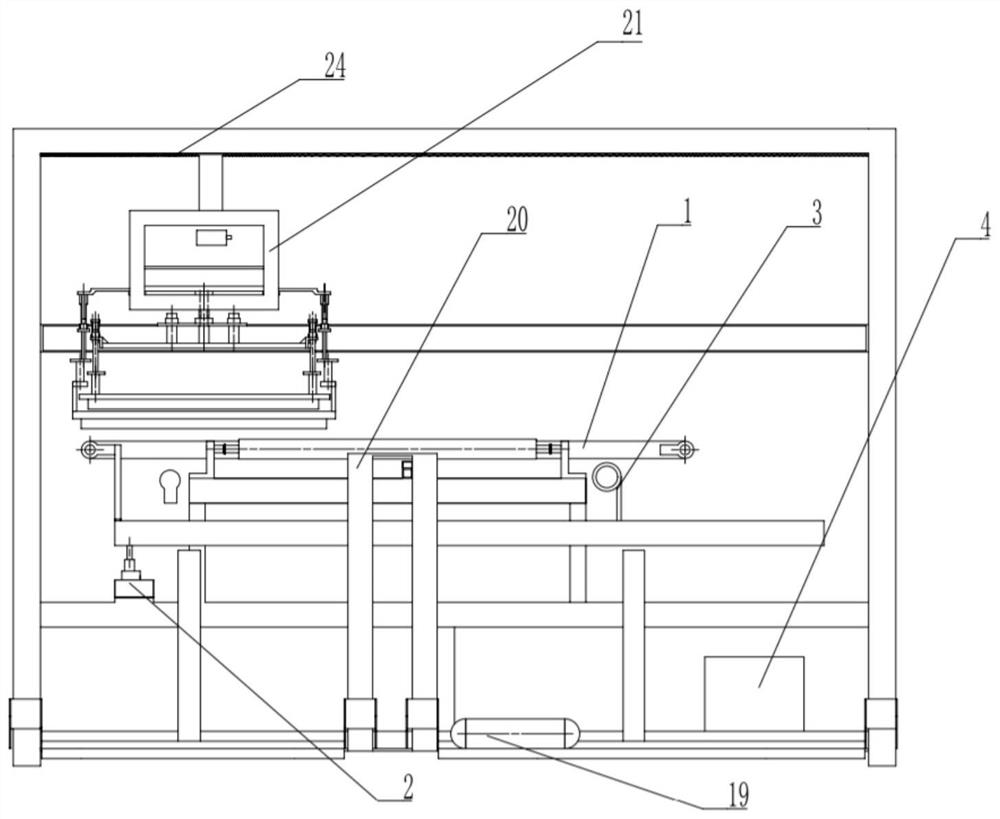

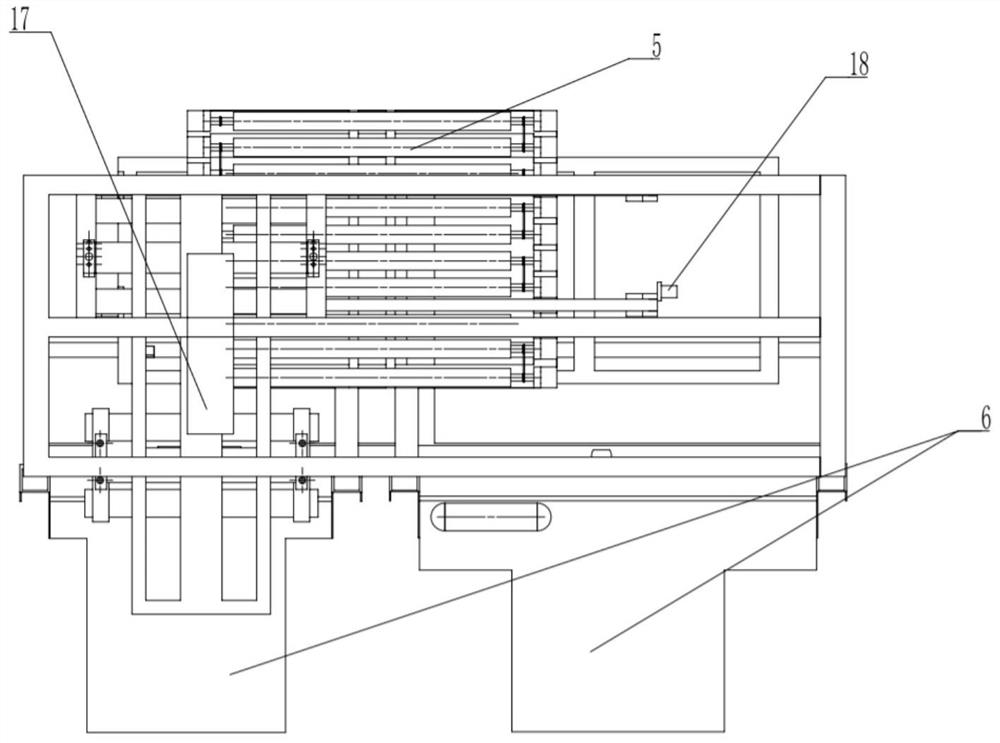

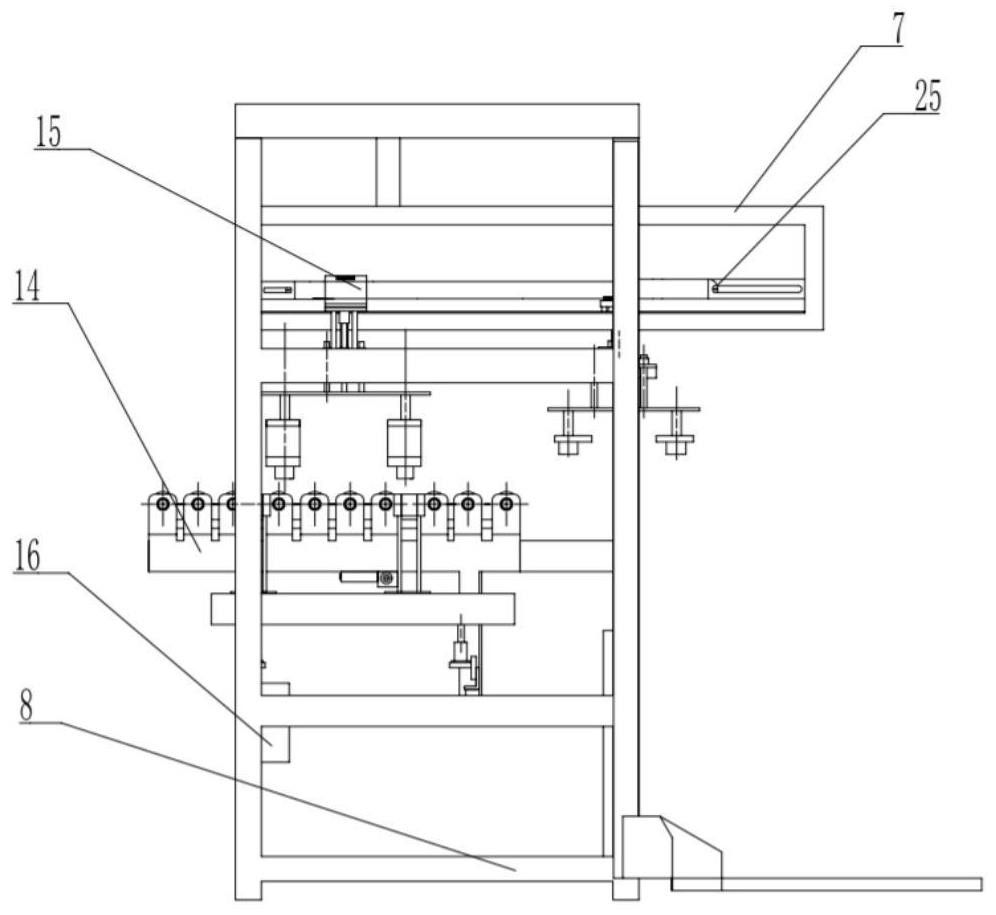

[0019] In the figure: 1-conveyor belt, 2-lifting mechanism, 3-motor, 4-electric system, 5-roller conveying mechanism, 6-hydraulic lifting platform, 7-double suction cup mechanism frame, 8-integral frame, 9-guiding Mechanism, 10-suction cup, 11-cylinder, 12-synchronous wheel, 13-suction cup mechanism, 14-roller mechanism bracket, 15-suction cup mechanism slider, 16-motor, 17-double suction cup moving mechanism, 18-motor, 19- Hydraulic mechanism, 20-hydraulic platform moving mechanism, 21-double suction cup mechanism, 22-buffer mechanism, 24-conveyor belt, 25-synchronous belt, 26-linear guide rail, 27-fixing device.

[0020] The present invention comprises frame 8, double sucker mechanism 21, double sucker moving mechanism 17, conveyor belt 24, conveyer belt 1, roller conveying mechanism 5, hydraulic lifting platform 6, lifting mechanism 2. The hydraulic lifting platform 6 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap