Composite coating containing cardanol-based reactive diluent modified graphene oxide filler as well as preparation method and application of composite coating

A reactive diluent and cardanol-based technology, applied in the field of composite coatings and its preparation, can solve problems such as difficult construction operations, poor long-term anti-corrosion performance, and ecological environment crisis, and achieve improved anti-corrosion performance, improved barrier effect, and simple construction and operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

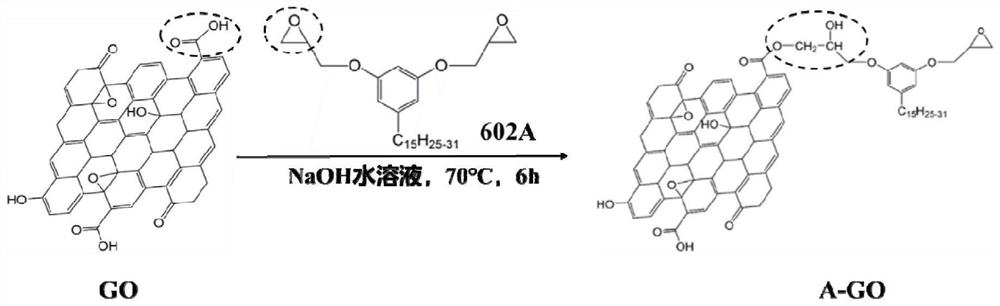

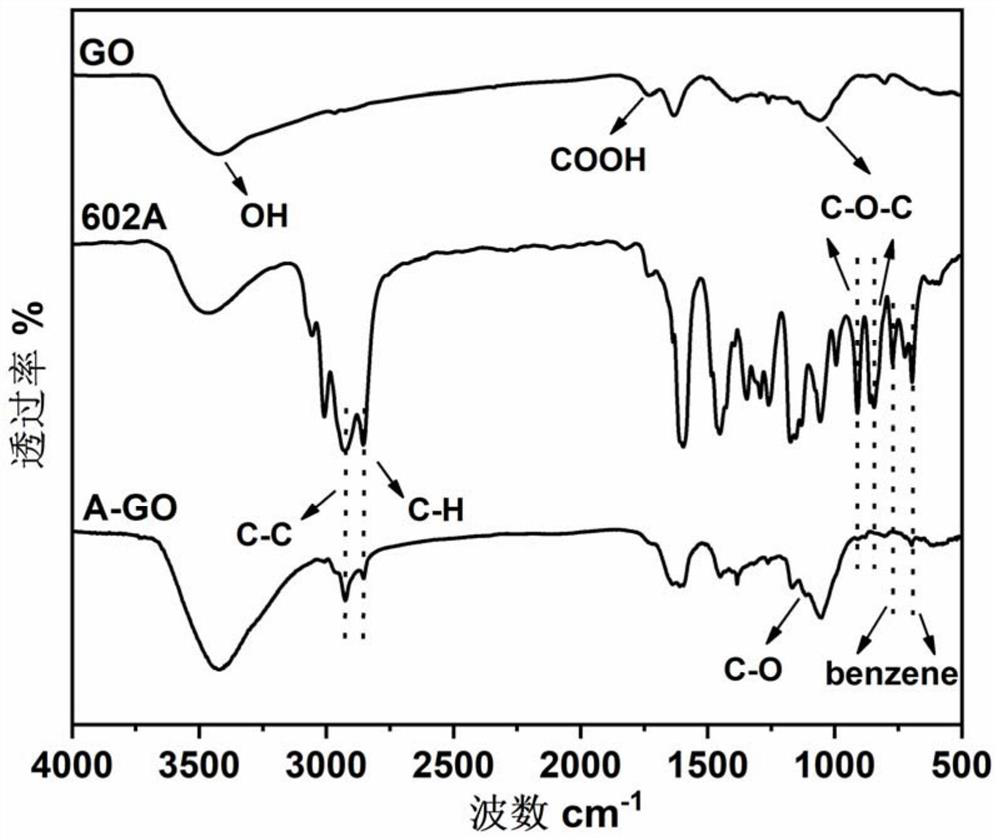

[0037] (1) Utilize the Hummer's method of high-power continuous ultrasonic exfoliation of graphite oxide to obtain a graphene oxide aqueous solution, and then disperse the graphene oxide in absolute ethanol by solvent replacement, ultrasonic and combined with 800r / min mechanical stirring for 30min to obtain a mixture A;

[0038] (2) Add cardanol-based reactive diluent to the mixture A in the three-necked flask, the mass ratio of cardanol-based reactive diluent to graphene oxide in step (1) is 1:1, ultrasonic and combined with 1000r / min mechanical Stir for 30min to obtain mixture B;

[0039] (3) Add 0.1mol / L NaOH aqueous solution dropwise to the mixture B as a reaction catalyst, the amount added dropwise is 1% of the mass of the mixture B, and mechanically stir at a speed of 600r / min in a water bath at 70°C for 7h to obtain a mixture C ;

[0040] (4) The mixture C was centrifuged and washed 5 times with absolute ethanol, the centrifugal speed was 4000r / min, and the centrifugat...

Embodiment 2

[0046] (1) Utilize the Hummer's method of high-power continuous ultrasonic exfoliation of graphite oxide to obtain a graphene oxide aqueous solution, and then disperse the graphene oxide in absolute ethanol by solvent replacement, ultrasonic and combined with 800r / min mechanical stirring for 30min to obtain a mixture A;

[0047] (2) Add cardanol-based reactive diluent to mixture A in a three-necked flask, the mass ratio of cardanol-based reactive diluent to graphene oxide in step (1) is 2:1, ultrasonic and combined with 1000r / min mechanical Stir for 30min to obtain mixture B;

[0048] (3) Add 0.2mol / L NaOH aqueous solution dropwise to the mixture B as a reaction catalyst, the amount added dropwise is 1% of the mass of the mixture B, and mechanically stir at a speed of 600r / min in a water bath at 80°C for 5h to obtain a mixture C ;

[0049] (4) The mixture C was centrifuged and washed 5 times with absolute ethanol, the centrifugal speed was 4000r / min, and the centrifugation ti...

Embodiment 3

[0055] (1) Utilize the Hummer's method of high-power continuous ultrasonic exfoliation of graphite oxide to obtain a graphene oxide aqueous solution, and then disperse the graphene oxide in absolute ethanol by solvent replacement, ultrasonic and combined with 800r / min mechanical stirring for 30min to obtain a mixture A;

[0056] (2) Add cardanol-based reactive diluent to the mixture A in the three-necked flask, the mass ratio of cardanol-based reactive diluent to graphene oxide in step (1) is 10:1, ultrasonic and combined with 1000r / min mechanical Stir for 30min to obtain mixture B;

[0057] (3) Add 0.1mol / L NaOH aqueous solution dropwise to the mixture B as a reaction catalyst, the amount added dropwise is 1% of the mass of the mixture B, and mechanically stir at a speed of 600r / min in a water bath at 70°C for 6h to obtain a mixture C ;

[0058] (4) The mixture C was centrifuged and washed 5 times with absolute ethanol, the centrifugal speed was 4000r / min, and the centrifuga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com