Pipeline carbon black removing device for recycling waste tires

A technology for waste tires and removal devices, which is applied in the fields of cleaning hollow objects, cleaning methods and utensils, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of time-consuming and laborious cleaning, easy blockage of pipes, etc., and achieves reduction of disassembly, easy falling off, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

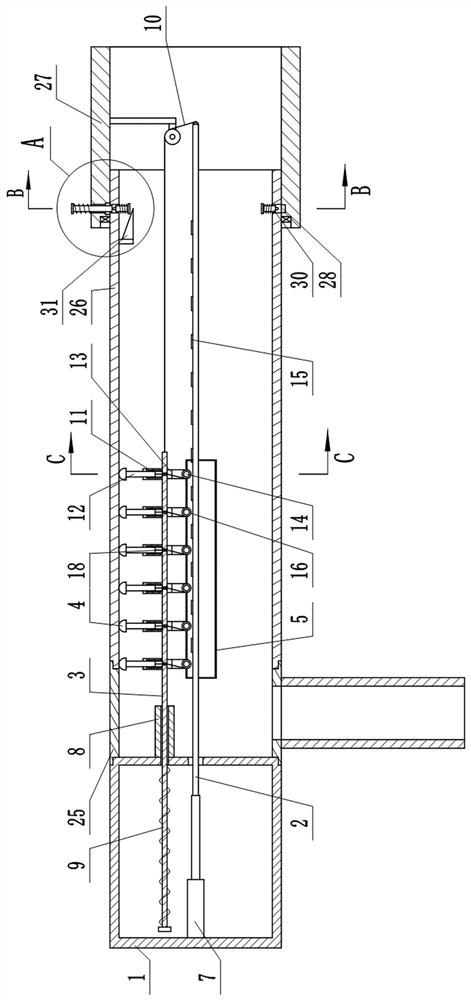

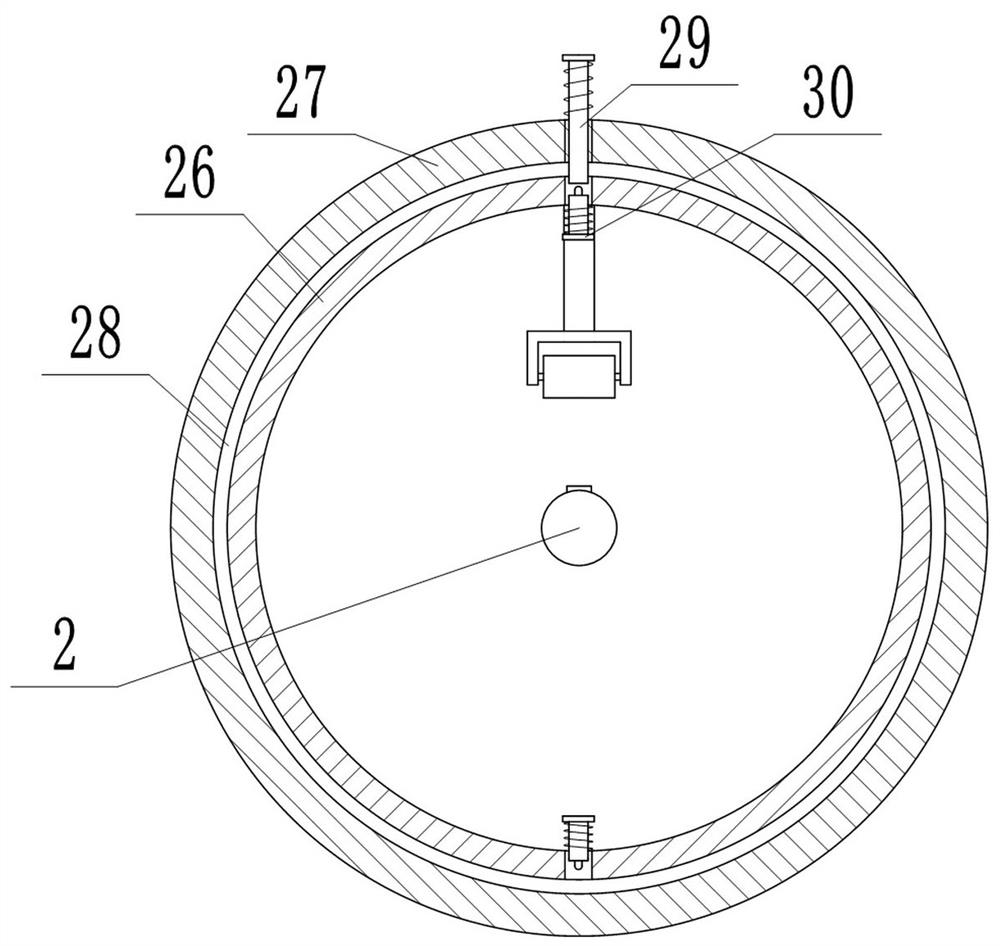

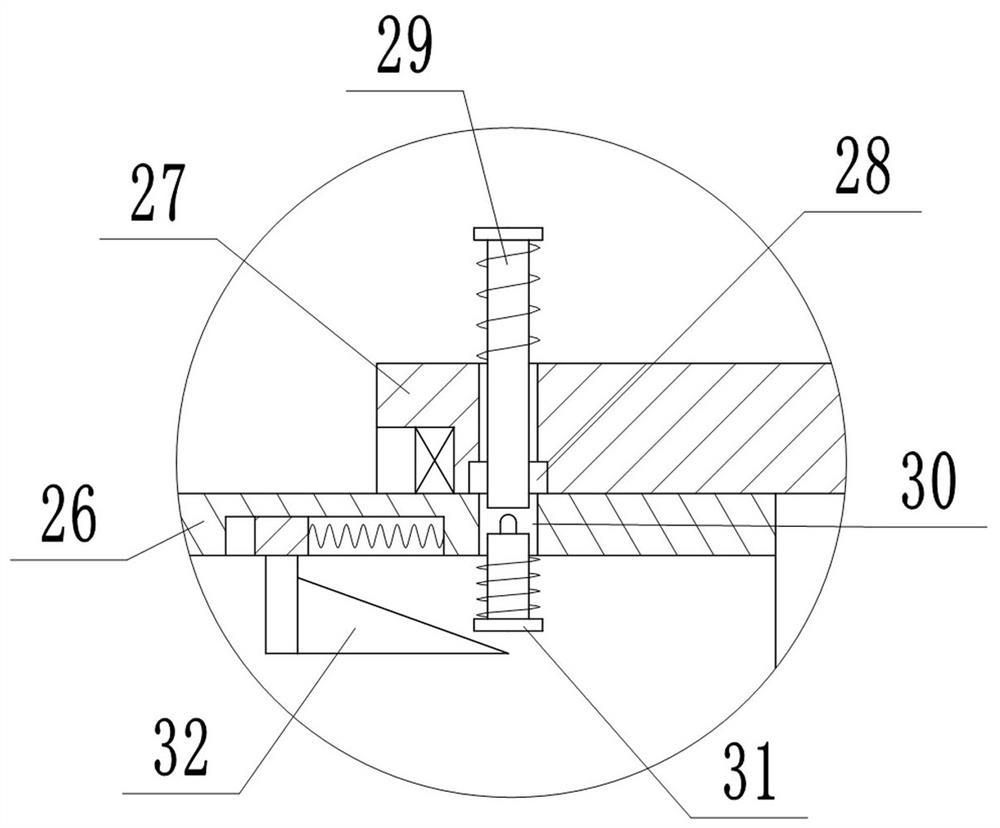

[0024] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] Depend on Figure 1 to Figure 8 Given, the present invention includes a horizontal horizontal tube 1 in the left and right directions. A horizontally placed horizontal shaft 2 is installed in the horizontal tube 1. The horizontal shaft 2 is coaxial with the horizontal tube 1 and can be moved along the horizontal axis. The horizontal tube 1 moves left and right, and a support plate 3 parallel to the horizontal axis 2 is installed above the horizontal axis 2, and the horizontal axis 2 can drive the support plate 3 to move in the opposite direction. There are a plurality of fan-shaped scrapers 4 evenly distributed on the left and right sides of the board 3. The fan-shaped scrapers 4 are coaxial with the horizontal tube 1, and the lateral movement of the horizontal axis 2 can make the fan-shaped scrapers 4 move up and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com