Method and apparatus for sputter deposition

A sputtering target, plasma technology, applied in the field of sputtering deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Reference in the specification to "an example" (or "an embodiment" or similar language) means that a particular feature, structure, or characteristic described in connection with the example is included in at least one example but not necessarily other examples. It should also be noted that certain embodiments are described schematically, with certain features omitted and / or simplified as necessary, in order to facilitate explanation and understanding of the concepts behind the embodiments.

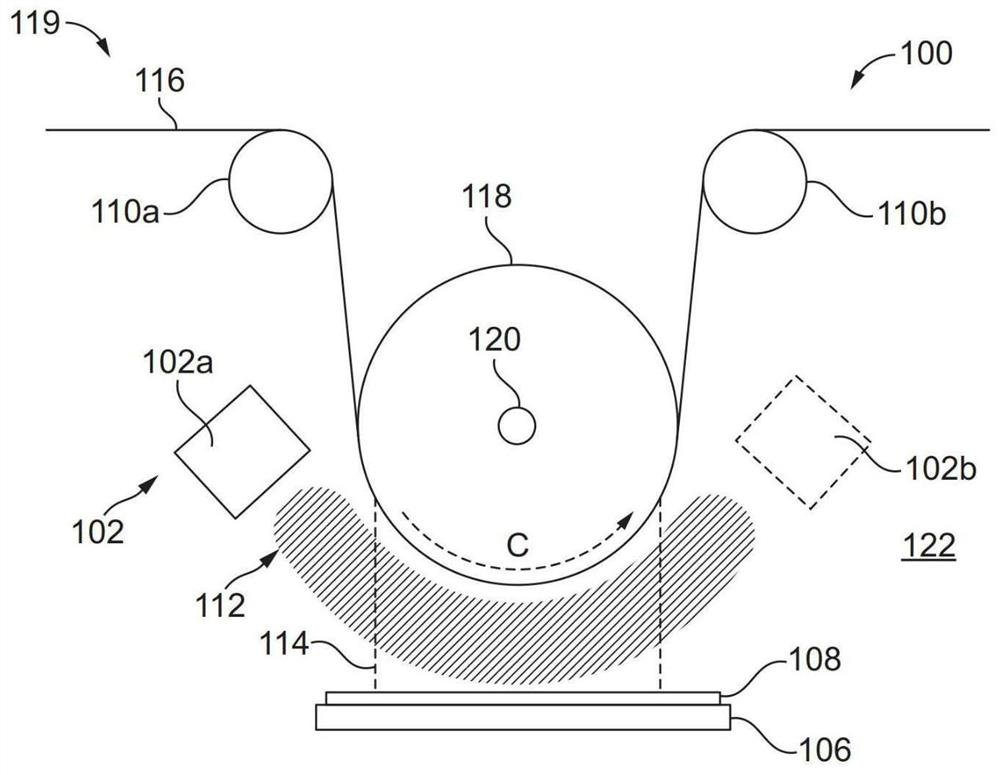

[0051] refer to figure 1 , illustrates an example apparatus 100 for sputter deposition of a target material 108 onto a substrate 116 . Apparatus 100 may be considered an example of a plasma reactor. Apparatus 100 can be used for plasma-based sputter deposition in a variety of industrial applications, such as those that can be used for thin film deposition, for example in optical coatings, magnetic recording media, electronic semiconductor devices, LEDs, thin film solar cells and o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com