Plane steel truss node connecting device

A node connection and steel truss technology, which is applied in the field of planar steel truss node connection devices, can solve the problem that the number and angle of the rods that can be installed at the connection node cannot be adjusted on site, so as to avoid quality defects, clear force transmission path, and quick replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

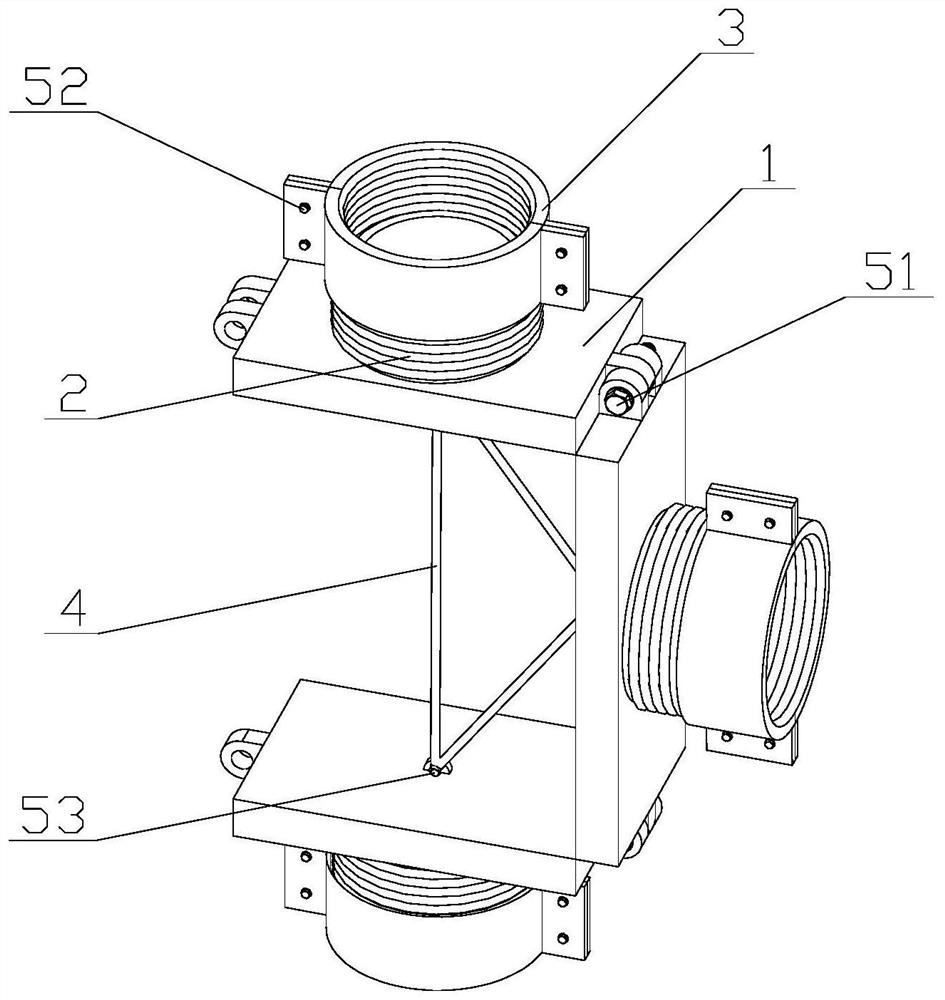

[0039] The planar steel truss node connection device provided by the present invention includes any number of connection units, and one connection unit includes an end plate 1 , a steel sleeve 2 , a detachable round pipe 3 , a flat head brace 4 , and a bolt 5 .

[0040] The end plate 1 includes a base 11 , a pair of circular platform clamping grooves 12 on the left, a single boss 13 on the right and a single anchoring seat 14 at the bottom.

[0041] The base 11 is a cuboid steel block, the length of which can be prefabricated according to the position of the planar rod, the width is slightly larger than the steel sleeve 2, and the thickness needs to be determined according to calculation, so as to ensure that the base will not be damaged by punching and shearing.

[0042] The circular platform clamping groove 12 is composed of two bosses 13, and the bosses 13 are composed of a cuboid and a half cylinder, and the height of the cuboid is consistent with the diameter of the half c...

Embodiment 2

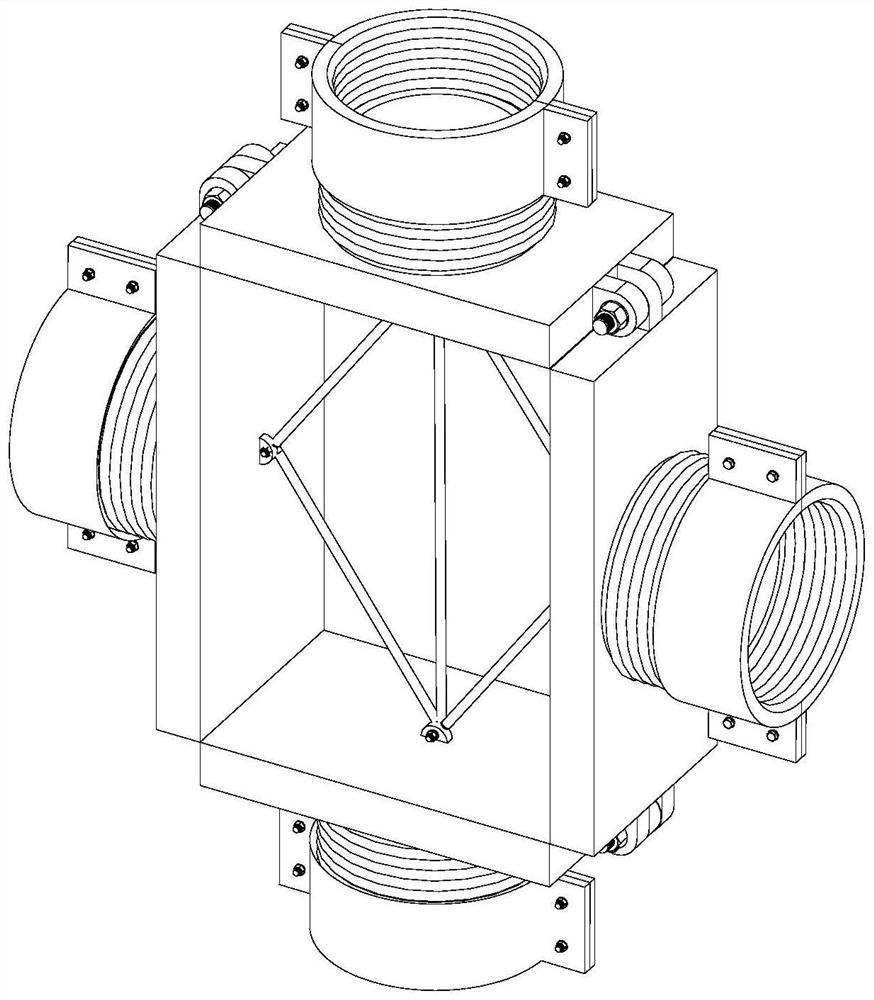

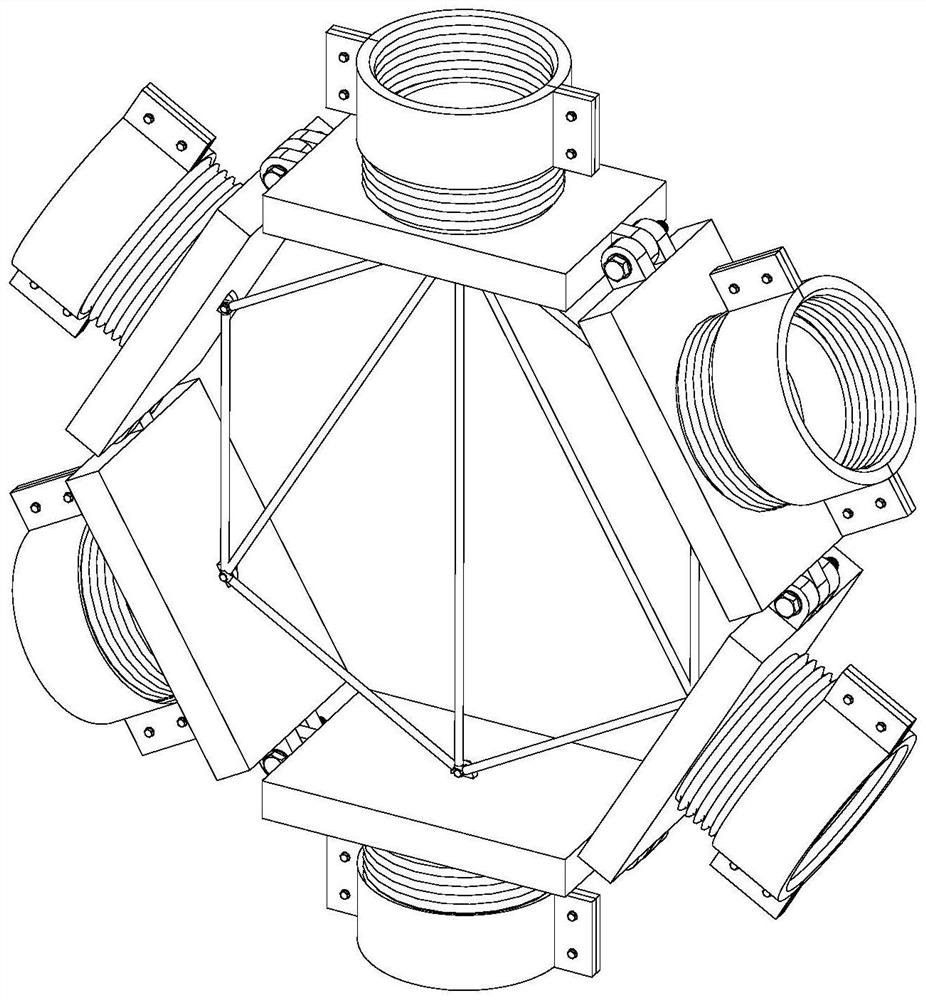

[0049] preferred embodiment, such as figure 1 , figure 2 , image 3 As shown, this embodiment includes an end plate 1, a steel sleeve 2, a detachable round pipe 3, a flat head strut 4, and a bolt 5, and is suitable for connection of any number of round pipes at any angle on the plane.

[0050] Such as figure 1 As shown, the end plate 1 includes a base 11, a circular platform clamping groove 12, a boss 13 and an anchoring platform 14, which can be mass-produced in advance in the factory.

[0051] Such as Figure 4 As shown, the base 11 is a cuboid solid steel plate, its main function is to transmit force, bear the external force transmitted by the steel truss tube, the adjacent end plate 1, and the flat head brace 4, and its length is determined according to the position of the plane steel truss tube. Ensure that all the end plates 1 of the whole device can be hinged into a body, and its width is 2 to 4 cm larger than the outer diameter of the steel sleeve 2, and the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com