Vibrating water pump with upper water inlet and lower water inlet

A double water inlet and water pump technology, applied in the direction of pumps, pump components, non-variable pumps, etc., can solve problems such as limited water inlet, difficulty in realizing fast water outlet operations with large displacement, and water pumps that cannot work normally. Simple, improve water inlet efficiency and quality, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

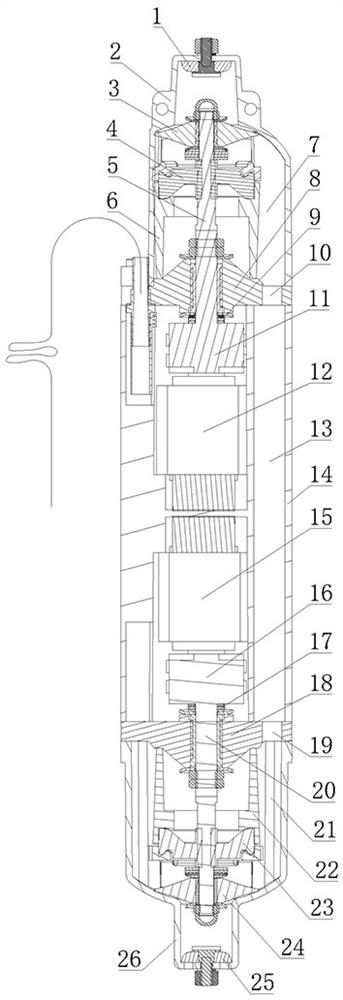

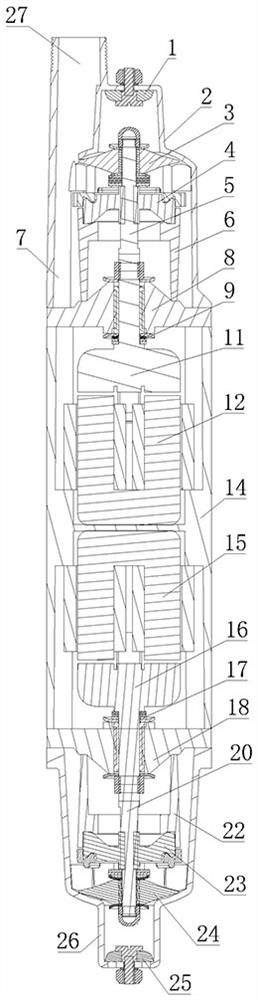

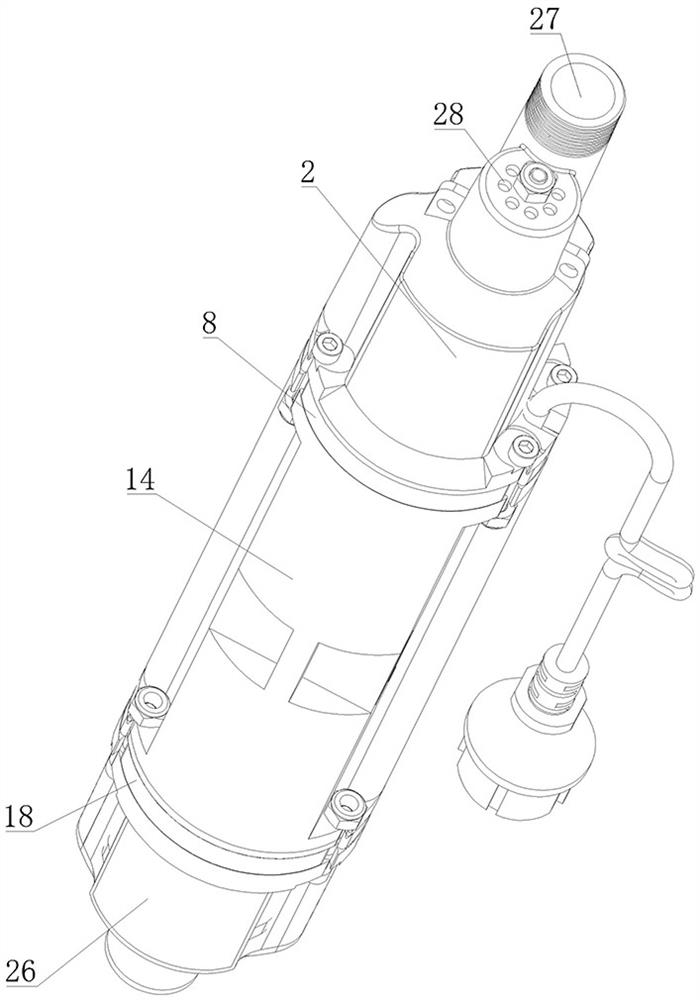

[0018] As shown in the figure, a vibrating water pump with upper and lower water inlets disclosed by the present invention includes an outer casing, the outer casing includes an upper cover 2, a barrel 14 and a lower cover 26, and the upper cover 2 is provided with an upper water inlet hole 28 and an outlet. The water outlet 27, the lower cover 26 is provided with a lower water inlet 29, the upper cover 2 is provided with a first one-way valve at the upper water inlet 28, and the lower cover 26 is provided with a second one-way valve at the lower water inlet 29 Specifically, the first one-way valve is a first rubber flap 1, and the first rubber flap 1 is installed inside the upper cover 2. The first rubber flap 1 can block the upper water inlet hole 28, and the second rubber flap 1 can block the upper water inlet hole 28. The one-way valve is a second rubber baffle 25, and the second rubber baffle 25 is installed inside the lower cover 26, and the second rubber baffle 25 can bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com