Method for testing fatigue crack growth rate of three-point bending sample in T-shaped wave load holding test

A technology of fatigue crack growth and crack growth rate, which is applied in the direction of testing the strength of materials by applying a stable bending force, which can solve the problem that the fatigue crack growth rate of materials cannot be directly measured, and achieve the effect of accurate data support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The present embodiment is the test method of the fatigue crack growth rate of the T-type wave load test three-point bending (SEB) sample, specifically as follows:

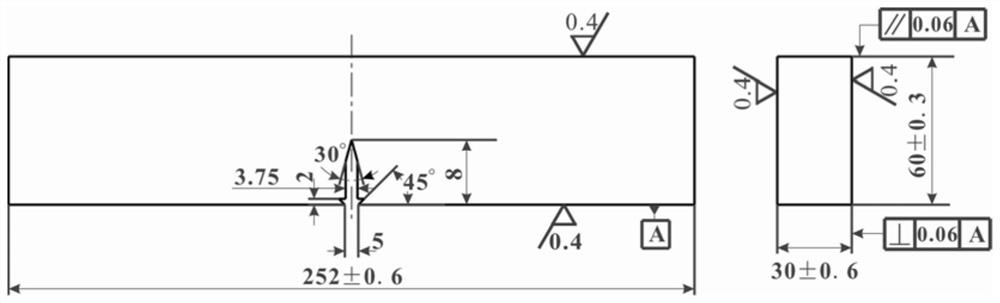

[0043] (1) Process the three-point bending (SEB) sample to be tested, and the sample size is as follows figure 1 Shown; measure and record B (sample thickness), W (sample width) and other dimensional information.

[0044] (2) Determine the stress intensity factor range △K corresponding to the crack propagation of the material, and calculate the required test load range △F according to the stress intensity factor range △K and formula (1);

[0045]

[0046] In the formula (1), △F is the test load range; B is the thickness of the sample; S is the span; W is the distance from the loading hole of the sample to the root of the sample; f(a / W) is the calculation parameter;

[0047]

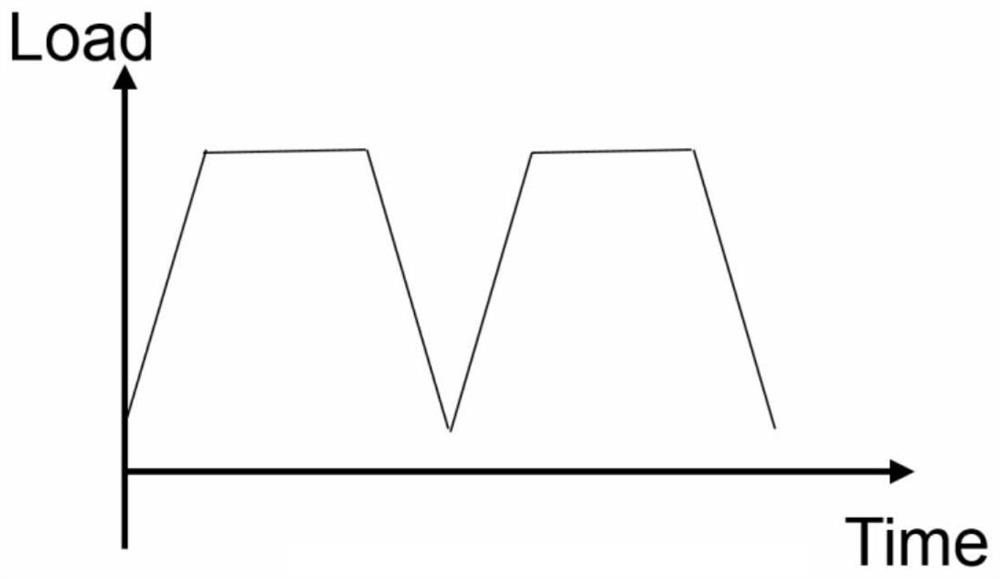

[0048] (3) Use the software on the electro-hydraulic servo fatigue testing machine to edit the test loading program, use the T-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com