High-quality imaging method and system for bolt ultrasonic detection

A technology of ultrasonic detection and imaging method, which is applied in processing the response signal of detection, using sonic/ultrasonic/infrasonic waves to analyze solids, etc., which can solve the problem that imaging resolution and signal-to-noise ratio are difficult to meet detection requirements, identify and analyze interference, defect leakage, etc. It can solve problems such as detection and misjudgment, and achieve good promotion and application prospects, improve defect detection capabilities, and suppress deformation wave echoes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

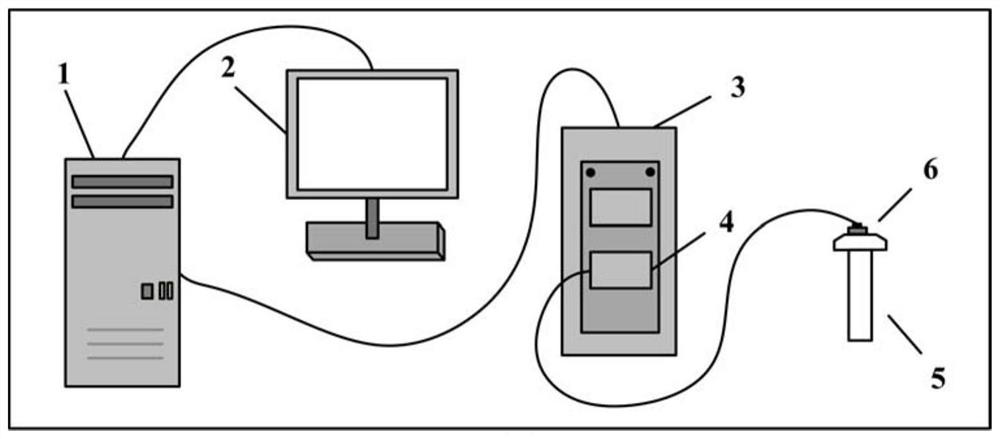

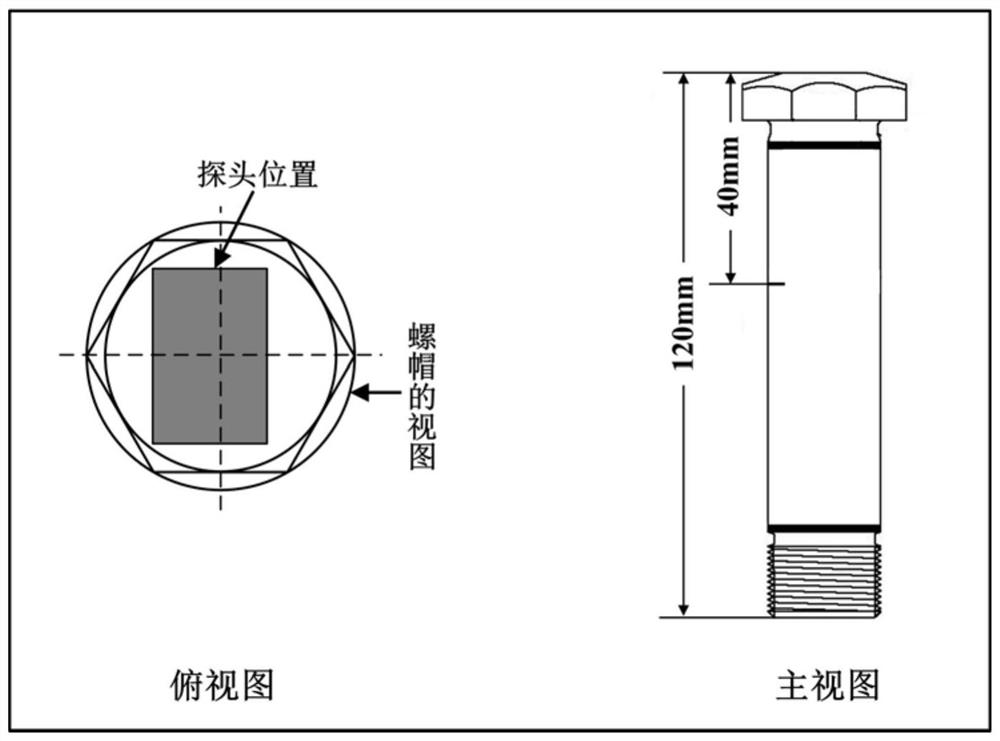

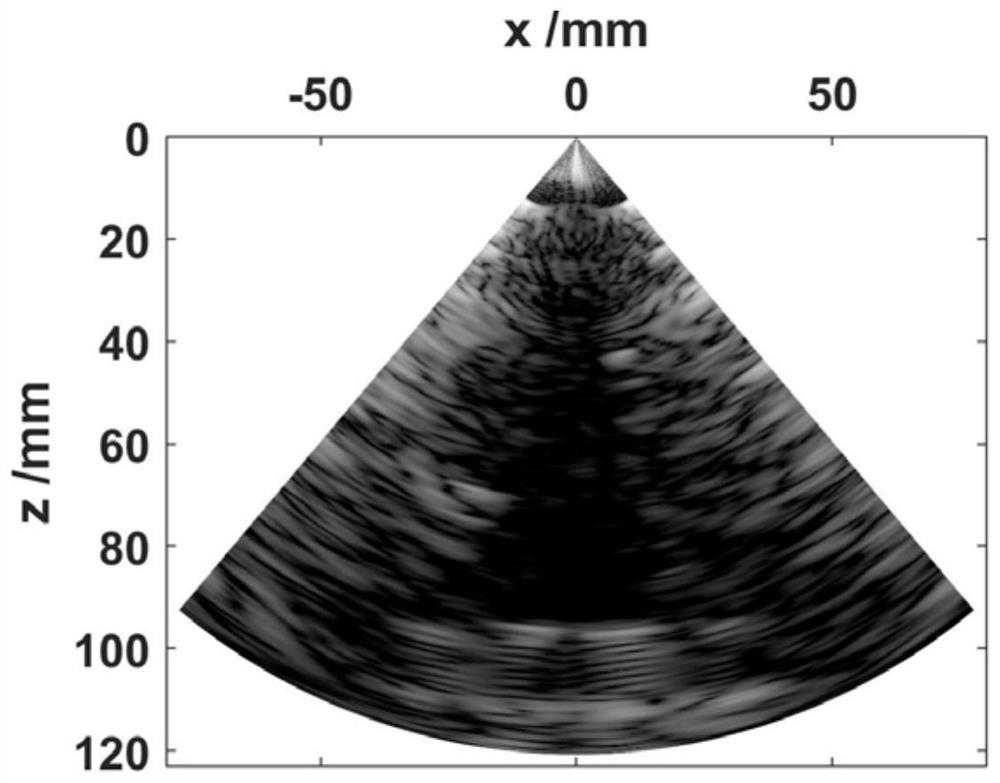

[0021] In this embodiment, taking the ultrasonic phased array detection of a steel bolt test block as an example, a high-quality imaging method for ultrasonic detection of bolts proposed by the present invention is further described. Such as figure 1 As shown, this scheme uses an ultrasonic detection system to image the specimen. The ultrasonic detection system includes a computer host 1, a display 2, a data acquisition system 3, a transducer connection panel 4 and a linear array transducer 5, wherein the linear array transducer The transducer is connected to the connection panel, and the connection panel is an ultrasonic transmitting / receiving 32-channel interface. The model of the linear array transducer 5 used in this scheme is L5L64-0.6×10-C77, the center frequency of the probe is 5MHz, and the length of the array element is 10mm , the distance between adjacent elements is 0.6mm. The data acquisition system is connected with the host computer and the display via PCI-E, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com