Shell, preparation method thereof and electronic equipment

A technology of shell and composite structure, applied in the direction of opto-mechanical equipment, telephone structure, photo-engraving process of pattern surface, etc., can solve the problems of monotonous appearance and inability to meet user needs, achieve rich appearance effects and improve product competition The effect of force, preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

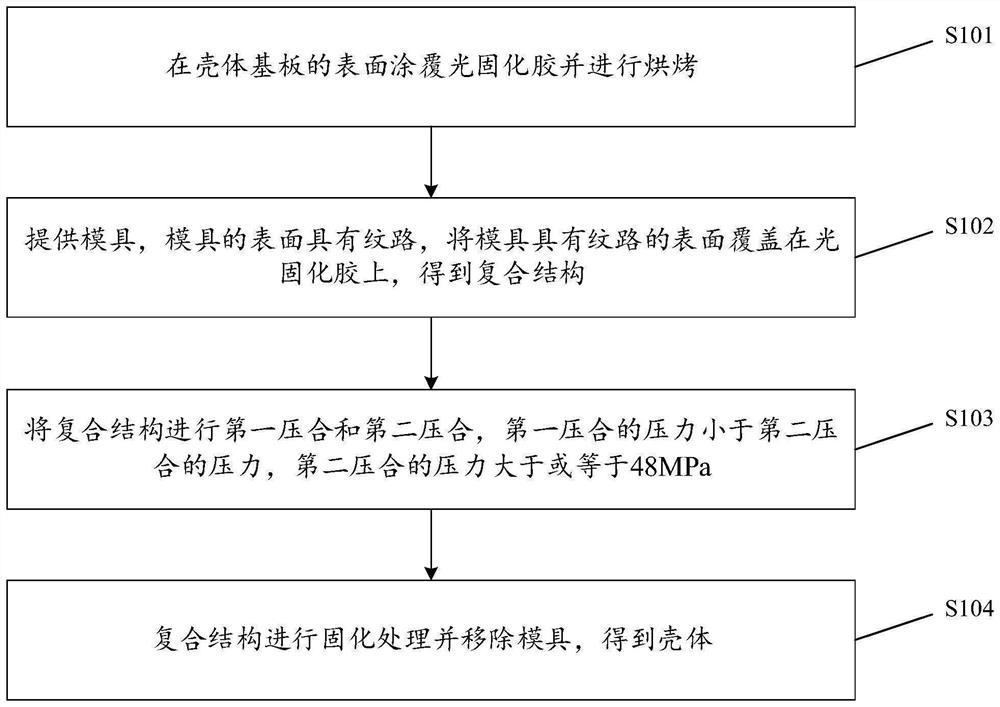

[0027] see figure 1 , is a flow chart of the preparation method of the housing provided in an embodiment of the present application, including:

[0028] S101: Coating and baking a photocurable glue on the surface of the housing substrate.

[0029] S102: Provide a mold, the surface of the mold has lines, and cover the surface of the mold with lines on the light-curing adhesive to obtain a composite structure.

[0030] S103: Perform the first pressing and the second pressing of the composite structure, the pressure of the first pressing is lower than the pressure of the second pressing, and the pressure of the second pressing is greater than or equal to 48 MPa.

[0031] S104: The composite structure is cured and the mold is removed to obtain a shell.

[0032] In order to improve the appearance effect of the shell substrate, a textured layer structure can be formed on the shell substrate by means of transfer printing. When the existing transfer printing process is used for tran...

Embodiment 1

[0082] The photocurable adhesive includes 10% of 2-functional urethane acrylic resin, 8% of 6-functional urethane acrylic resin, 19% of 9-functional urethane acrylic resin, 1.5% of photoinitiator (TPO and photoinitiator 184), 1% of auxiliary agent And the balance of organic solvents (isobutanol, butyl acetate and propylene glycol methyl ether acetate). The light-curable glue is spray-coated on the surface of the polymethyl methacrylate plate with 3D structure, hung in the baking device, and baked at 65°C for 5 minutes, so that the solid content of the light-curable glue is about 38%.

[0083] Cover the surface of the light-curing adhesive with a textured mold, and place a silicone pad on the surface of the mold to obtain a composite structure; seal the composite structure with a polyethylene film and vacuumize it to 9.8Pa. After pressing for 30 seconds, place the composite structure under water pressure. The tank is pressed at 50Mpa for 50s.

[0084] The composite structure i...

Embodiment 2

[0087] It is roughly the same as Example 1, except that different templates are used, and the pressure of the first pressing is 15Pa, the pressing time is 25s, the pressure of the second pressing is 48MPa, and the pressing time is 55s, and the shell is obtained body. see Figure 12 , is a schematic diagram of the surface texture of the shell prepared in Example 2. It can be seen that the shell prepared in Example 2 has a snowflake texture through observation with a 200-fold optical magnification lens, which enriches the appearance of the shell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com