Remote management method and system based on virtual reality

A remote management and virtual reality technology, applied in the field of digital twins, can solve problems such as the inability to accurately describe the real-time status of the factory, the inability to achieve transparent production, and the limitation of efficient factory management, so as to improve production efficiency and equipment utilization. The effect of equipment downtime, improved management efficiency and plant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Before carrying out the description of the specific embodiments of the present invention, the overall design of the present invention is described as follows:

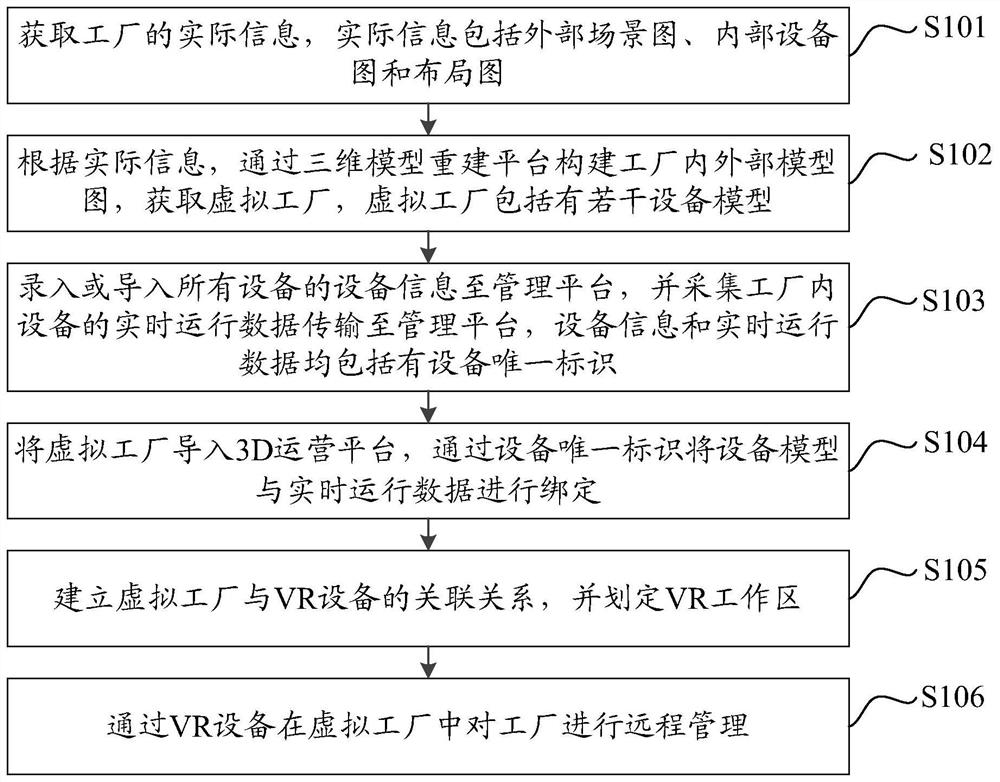

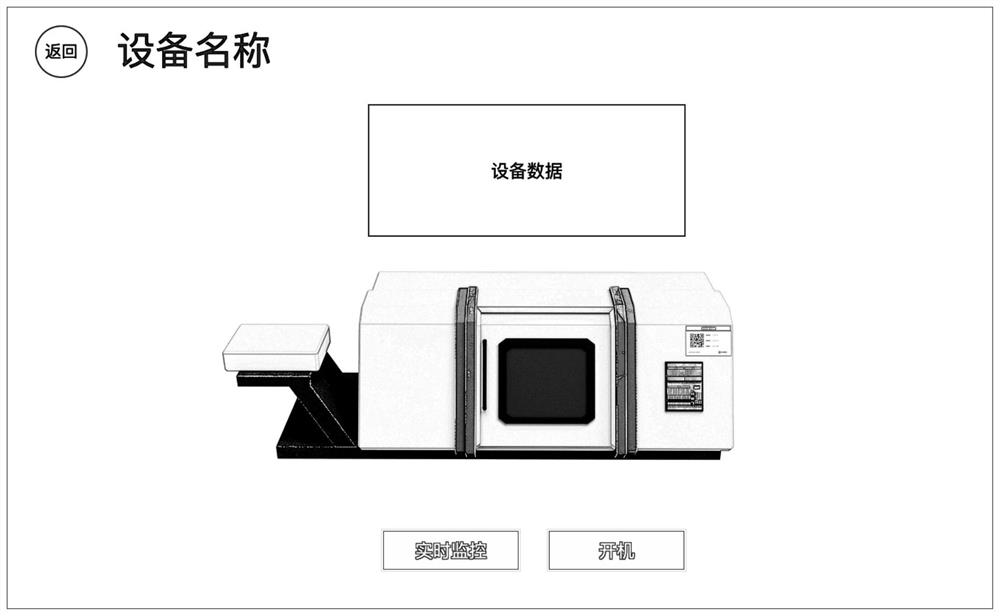

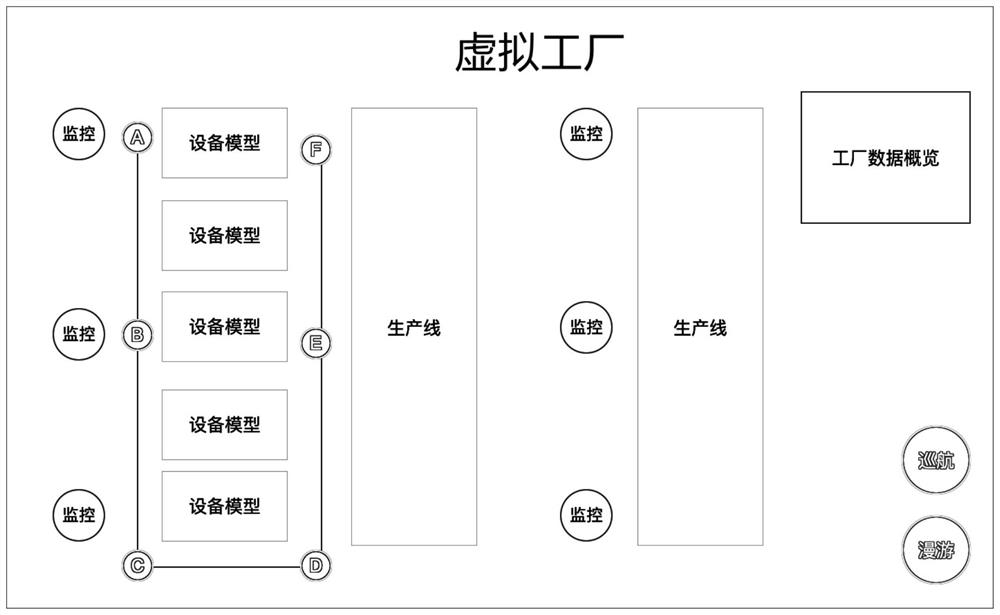

[0022] With the continuous development of digital twin technology, the digital factory system has a huge market demand in the construction of modern manufacturing enterprises. Therefore, the present invention proposes a remote management method based on virtual reality, obtains the actual information of the factory, uses a three-dimensional model reconstruction platform, builds the internal and external models of the factory based on the actual information, obtains the virtual factory, and enters or imports the equipment information of all equipment in the factory To the management platform, collect the real-time operation data of the equipment in the factory, and transmit it to the management platform, import the internal and external models of the factory into the 3D operation platform, and bind the equipment m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com