Aircraft structural part drilling and riveting quality control method based on digital twinning

A quality control method and technology for aircraft structural parts, applied in electrical digital data processing, instruments, design optimization/simulation, etc., can solve problems such as uneven stress distribution of riveting joints, error accumulation, and inability to monitor and warn the surface state, so as to avoid The effect of accumulating riveting errors, avoiding monitoring lag, and improving hole making and riveting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

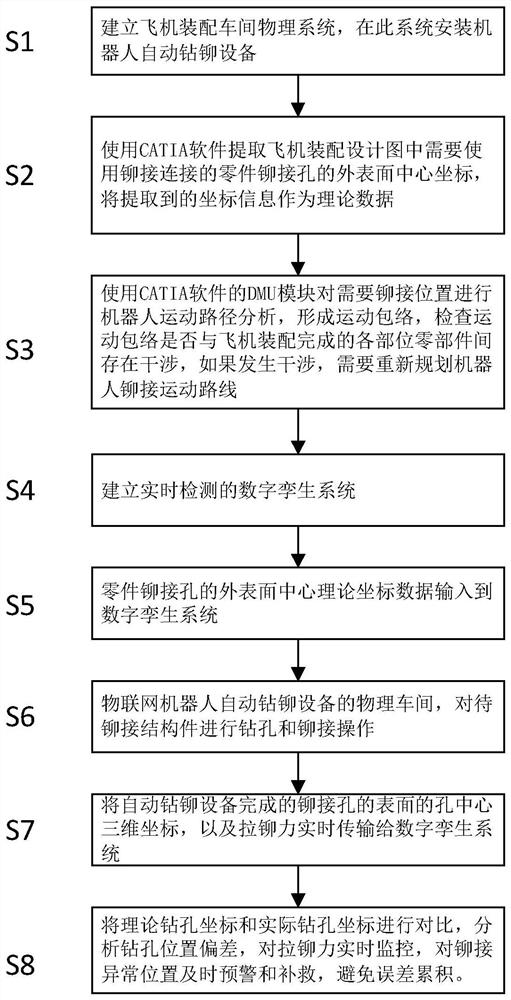

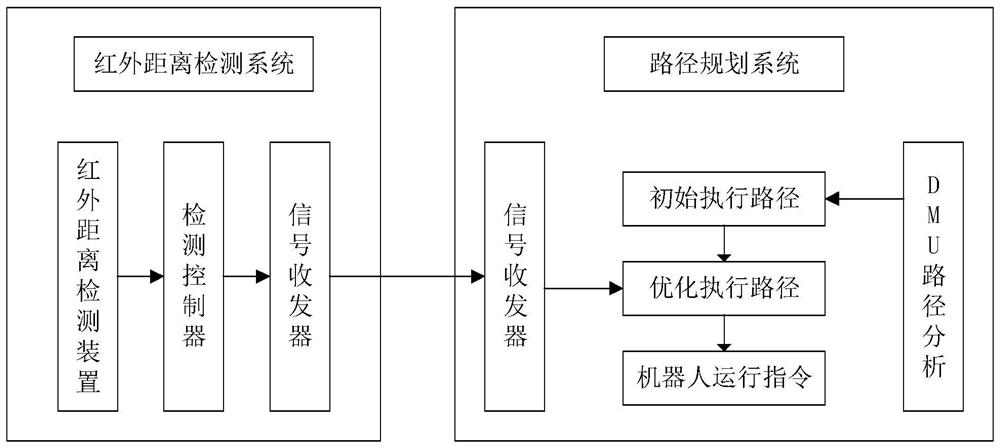

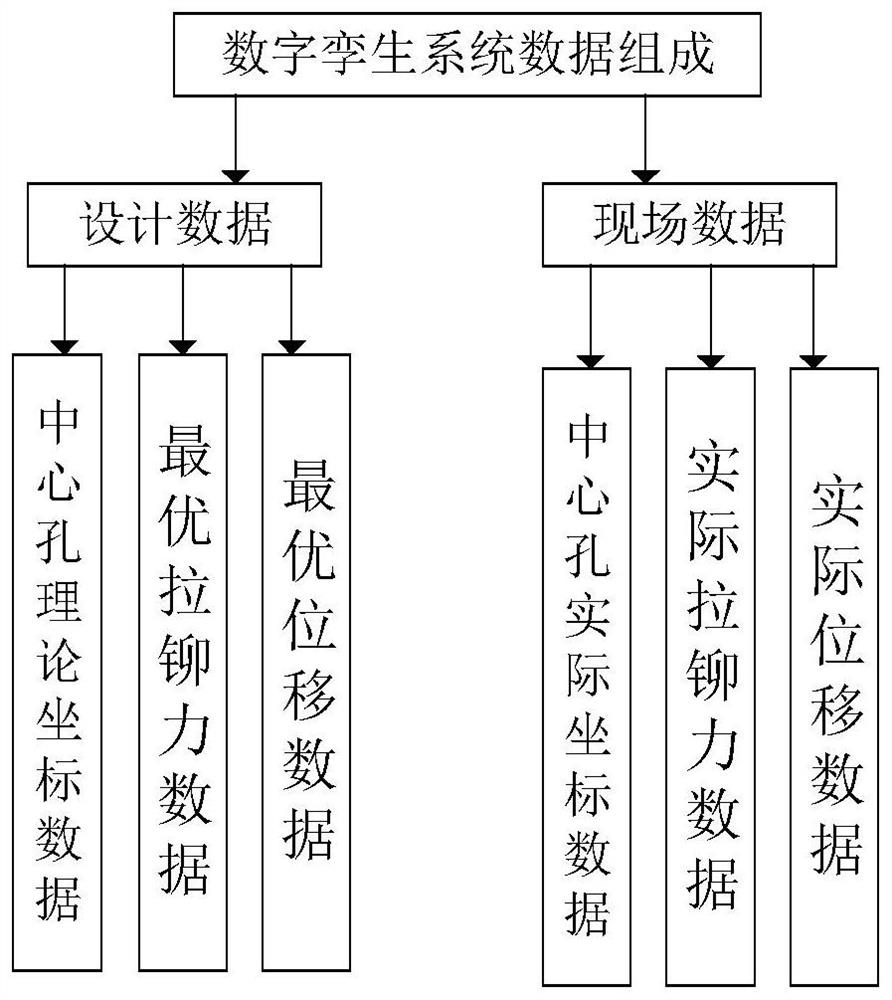

[0025] see figure 1 , the embodiment of the present invention discloses a digital twin-based method of hole making and riveting quality control of aircraft structural parts, establishes a physical system of an aircraft assembly workshop, and installs an automatic drilling and riveting device for an Internet of Things robot in this system. The riveting gun integrated with this device can Collect the riveting force and displacement data during the riveting process, monitor each riveting process, and transmit the actual coordinates of the drilled hole position and the riveting force and displacement of each rivet to the digital twin in real time through the LAN and TCP / I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com