Industrial robot positioning precision reliability analysis method based on evidence theory

A technology for industrial robots and positioning accuracy, applied in electrical digital data processing, instruments, complex mathematical operations, etc., can solve problems such as the inability to reasonably quantify the cognitive uncertainty of robot modeling parameters, and ignore the correlation of connecting rod size parameters. Achieve the effects of reducing over-conservative estimates, reducing solution costs, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principle of the present invention.

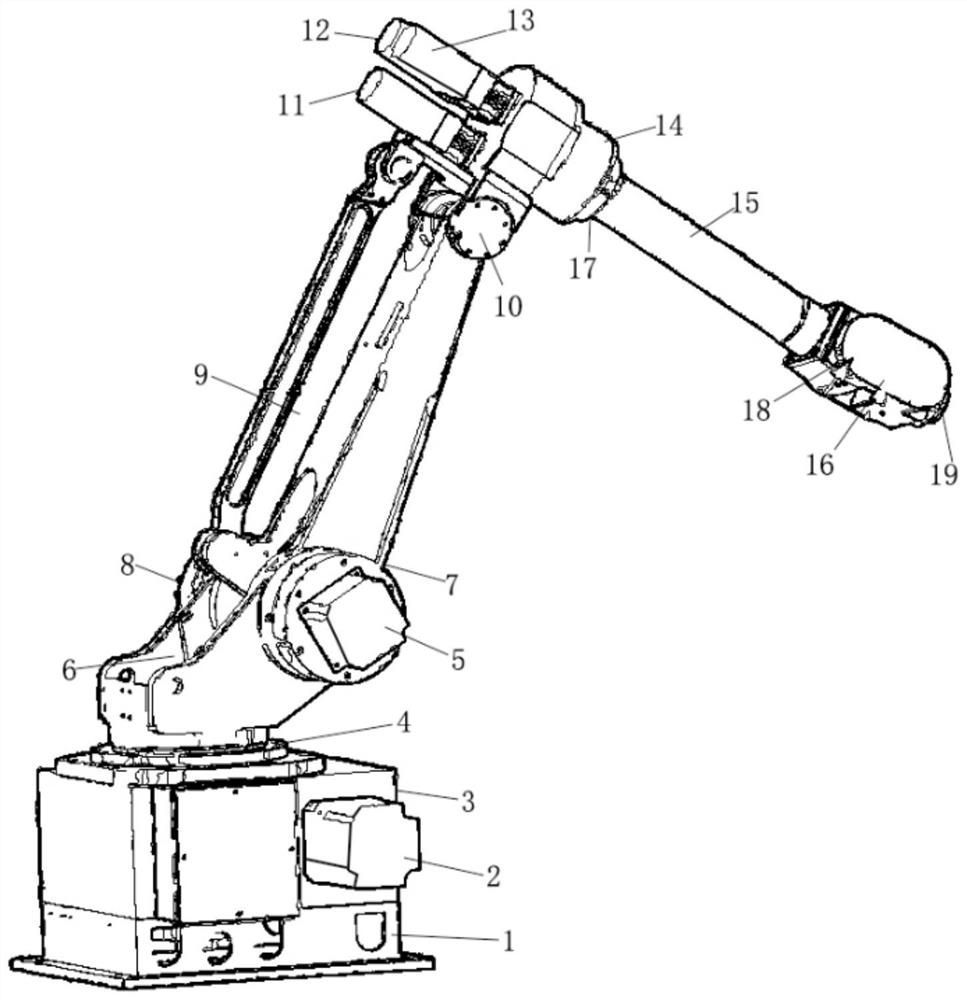

[0038] The present invention can be used for reliability analysis of positioning accuracy of all types of industrial robots. In order to describe the technical solution of the present invention in more detail, a six-degree-of-freedom serial industrial robot is used as an example for description.

[0039] The reliability analysis method of industrial robot positioning accuracy based on evidence theory specifically includes the following steps:

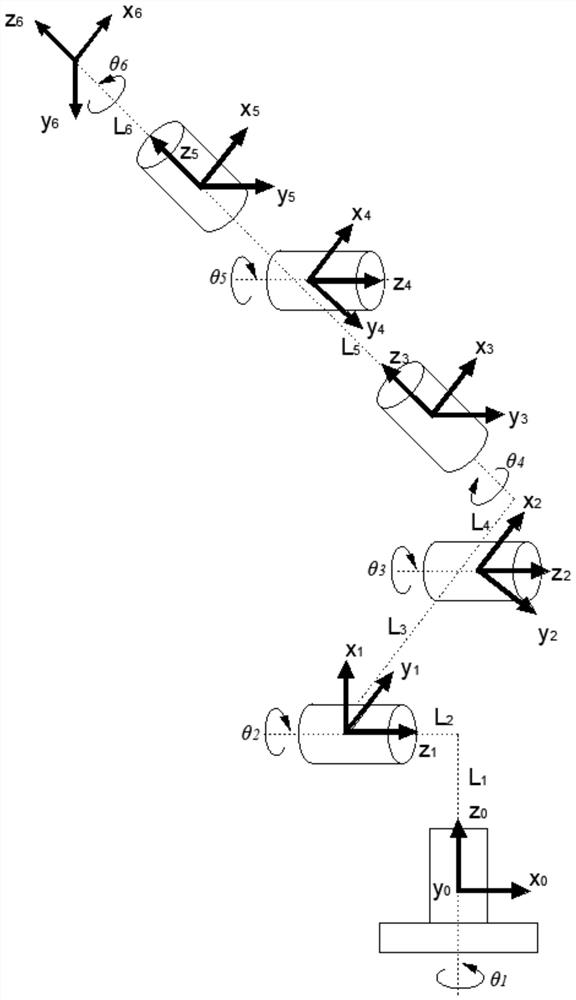

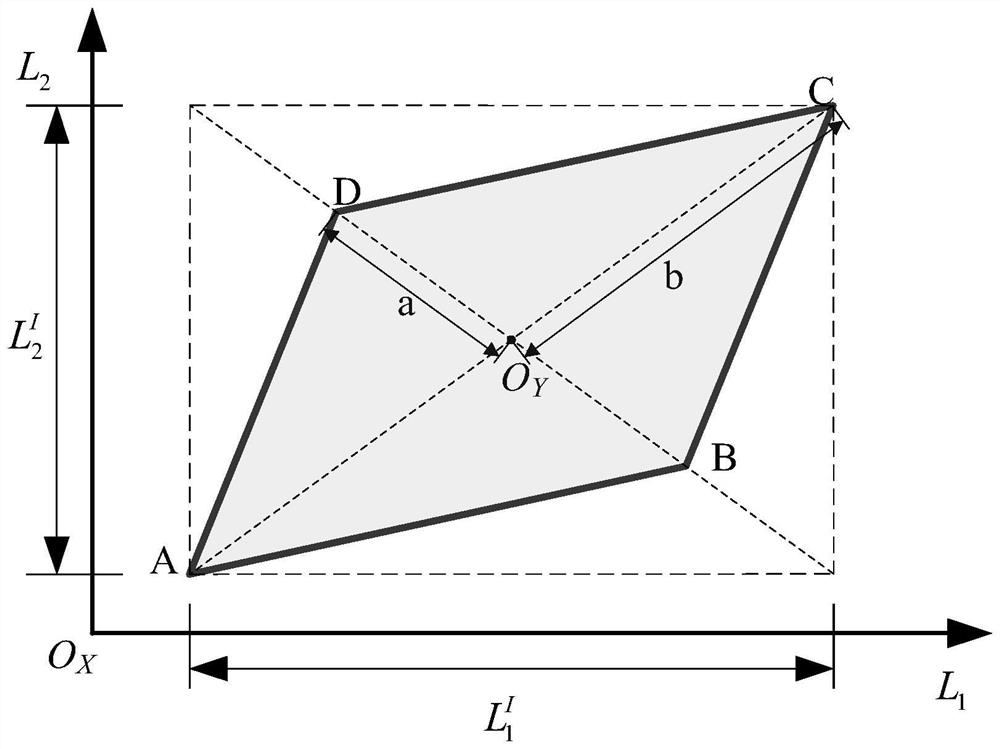

[0040] Step 1: Establish a reference coordinate system at each link joint of the industrial robot, establish a homogeneous transformation matrix between adjacent reference coordinate systems, and derive the link len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com