Cascade utilization battery cell, battery module and disassembly method of cascade utilization battery cell

A battery module and cell technology, which is applied in the manufacture of secondary batteries, battery pack components, circuits, etc., can solve the problem of high maintenance costs when the Pack system is discarded or completely disassembled, and the cells and the shell cannot be quickly separated, and it is not easy to Replacement of batteries and other issues, to achieve the effect of improving comprehensive economic benefits, easy maintenance, quick disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

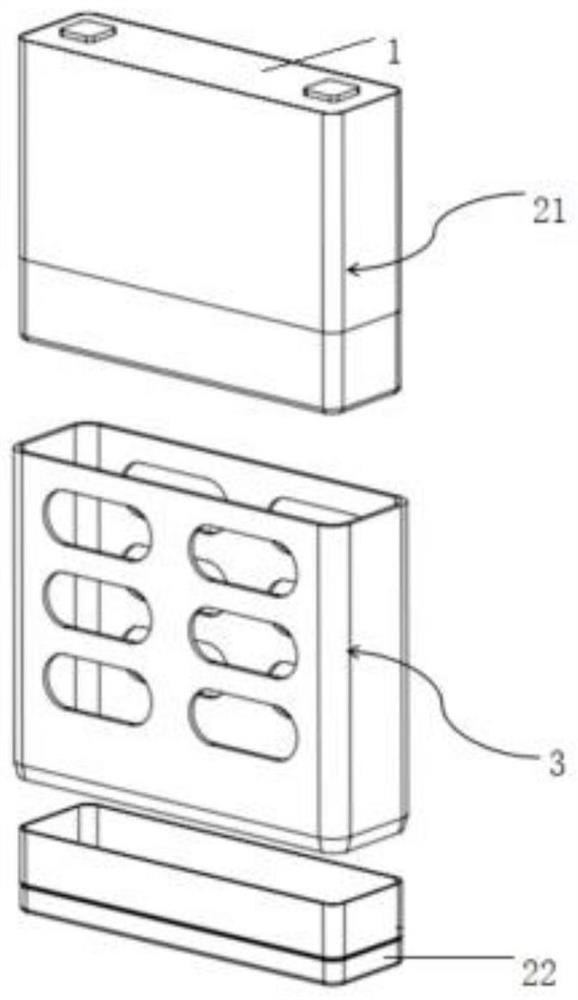

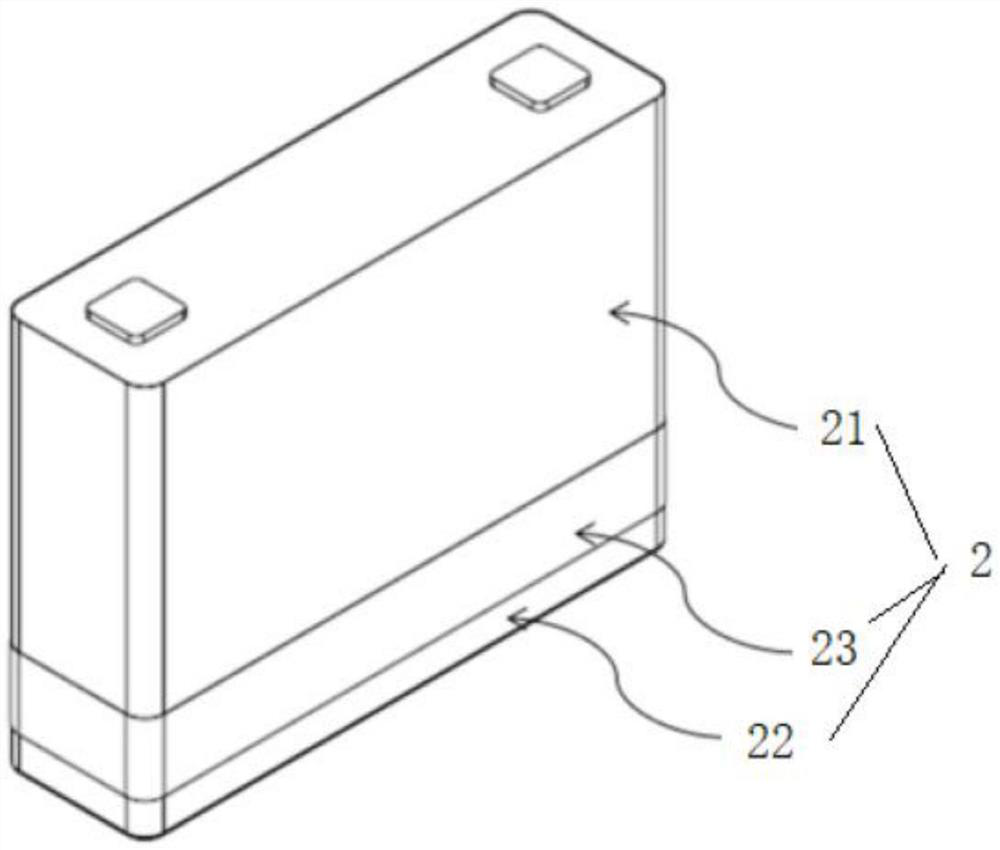

[0034] The invention provides a cascade utilization cell, such as figure 1 with 3 As shown, it includes battery 1 and blue film 2, and blue film 2 is connected to the outer wall of battery 1; blue film 2 includes first blue film 21, second blue film 22 and easy-to-pull blue film 23, first blue film 21 The blue film 23 is connected to the second blue film 22, and the first blue film 21 and the second blue film 22 are respectively connected to both ends of the cell. The integrated blue film 2 is wrapped on the outside of the battery cell 1 .

[0035] More specifically, after the easy-pull blue film 23 is cut by the film cutter 3 , the second blue film 22 is separated from the first blue film 21 , and the battery cell 1 is separated from the second blue film 22 . The film cutter 3 includes a housing 31 and a blade 32 , and the bottom of the housing 31 is connected to the blade 32 . Wherein, the inner diameter of the casing 31 >the outer diameter of the battery cell 1 , and the...

Embodiment 2

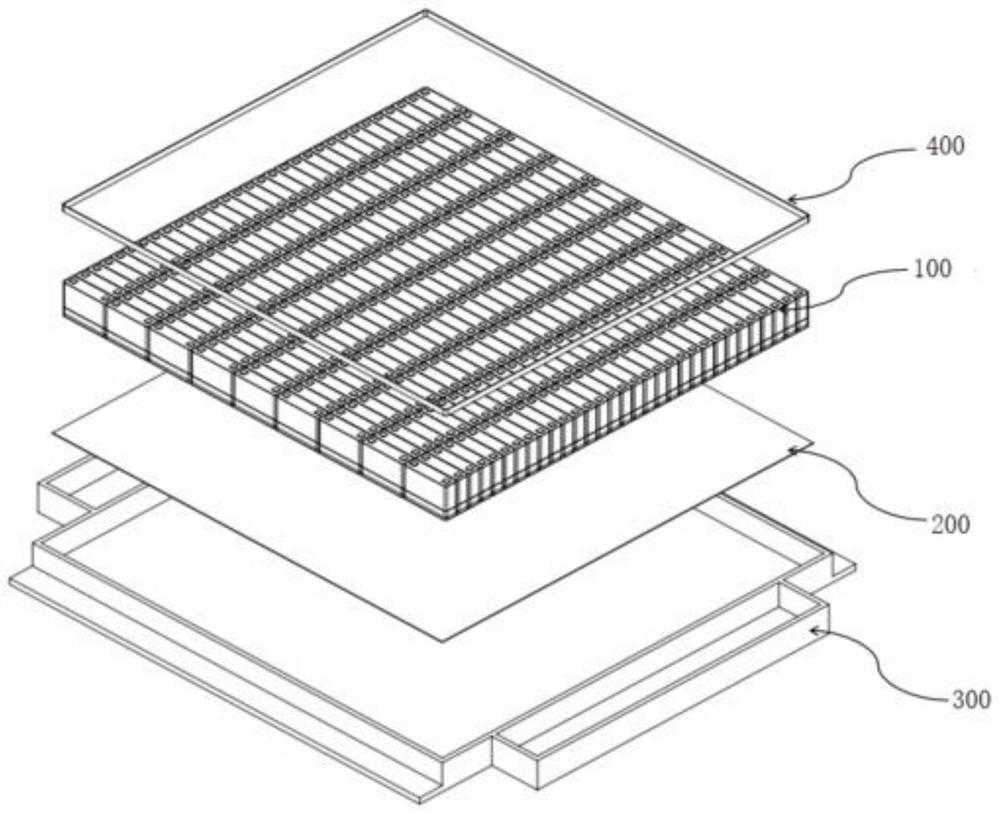

[0037] The present invention also provides a battery module, such as figure 2 As shown, it includes the cascade utilization cell 100 , the adhesive layer 200 , the battery pack case 300 and the connector 400 in Embodiment 1. The bottom of the cascade utilization cell 100 is connected to the battery pack case 300 through the adhesive layer 200 . More specifically, the second blue film 22 is connected to the battery pack case 300 through the adhesive layer 200 . The cascaded battery cells 100 are arranged in an array on the battery pack case 300 , and multiple cascaded battery cells 100 are fixed through the connector 400 . Preferably, the connecting member 400 may be in the form of a strap or a plurality of pieces of material with structural strength welded or bolted. As shown in the figure, in the second embodiment, the connecting member 400 is fixed on the outside of multiple cascaded battery cells 100 by using straps.

Embodiment 3

[0039] This embodiment 3 is completed on the basis of embodiment 2. When a cell 1 fails, it is necessary to remove a single cell 1, such as Figure 4-5 shown, including the following steps:

[0040] S1, snap the film cutter 3 into the outer surface of the battery cell 1, apply force to the easy-pull blue film 23 through the film cutter 3, so that the easy-pull blue film 23 is separated from the first blue film 21 and the second blue film 22;

[0041] S2, the detachment of the easy-to-pull blue film 23, so that the battery cell 1 is separated from the second blue film 22, and the battery cell 1 is taken out;

[0042] S3, removing the second blue film 22 on the battery pack case 300 and the glue layer 200 connected to the second blue film 22;

[0043] S4. Replace with a new battery cell 1 to complete the maintenance.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap