Power distribution cabinet for power transmission

A technology for power transmission and power distribution cabinets, which is applied in substation/power distribution device housings, electrical components, substation/switch layout details, etc., and can solve problems such as unfavorable power distribution cabinets, burnout of electronic components, and inconvenience to operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the present invention is further illustrated in connection with the specific embodiments.

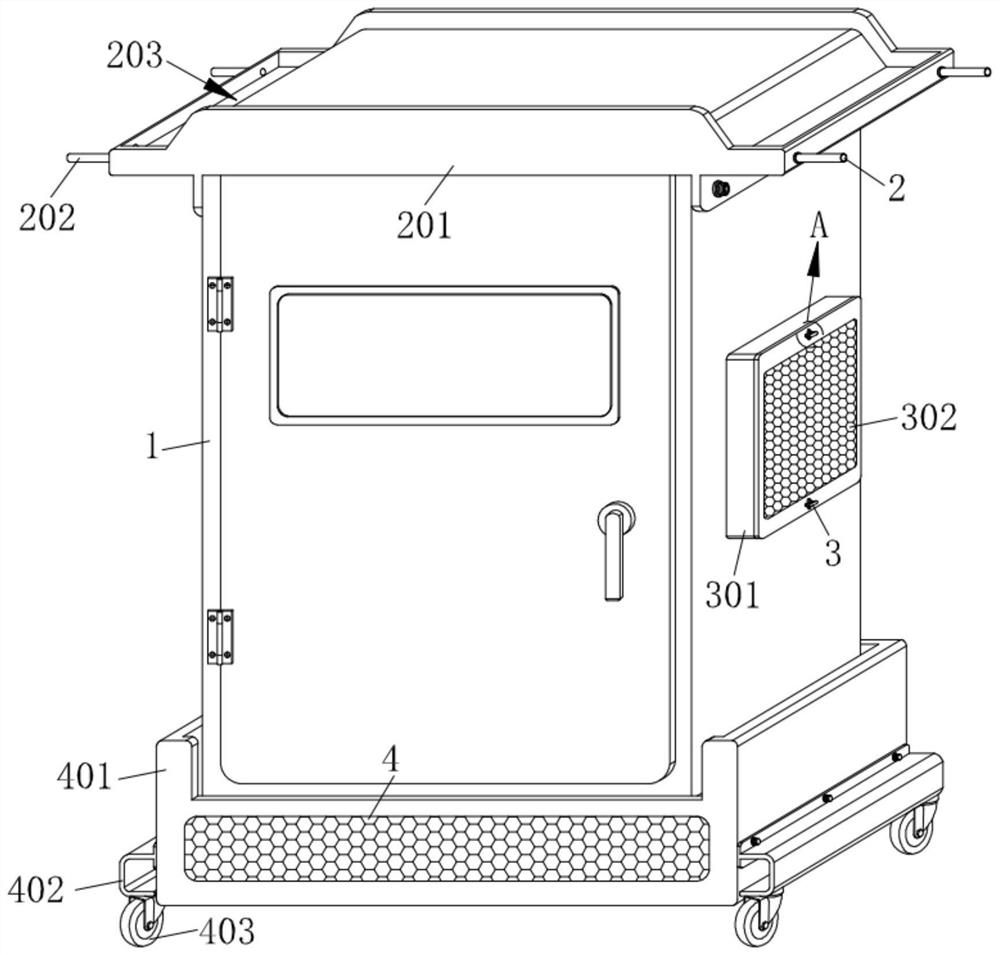

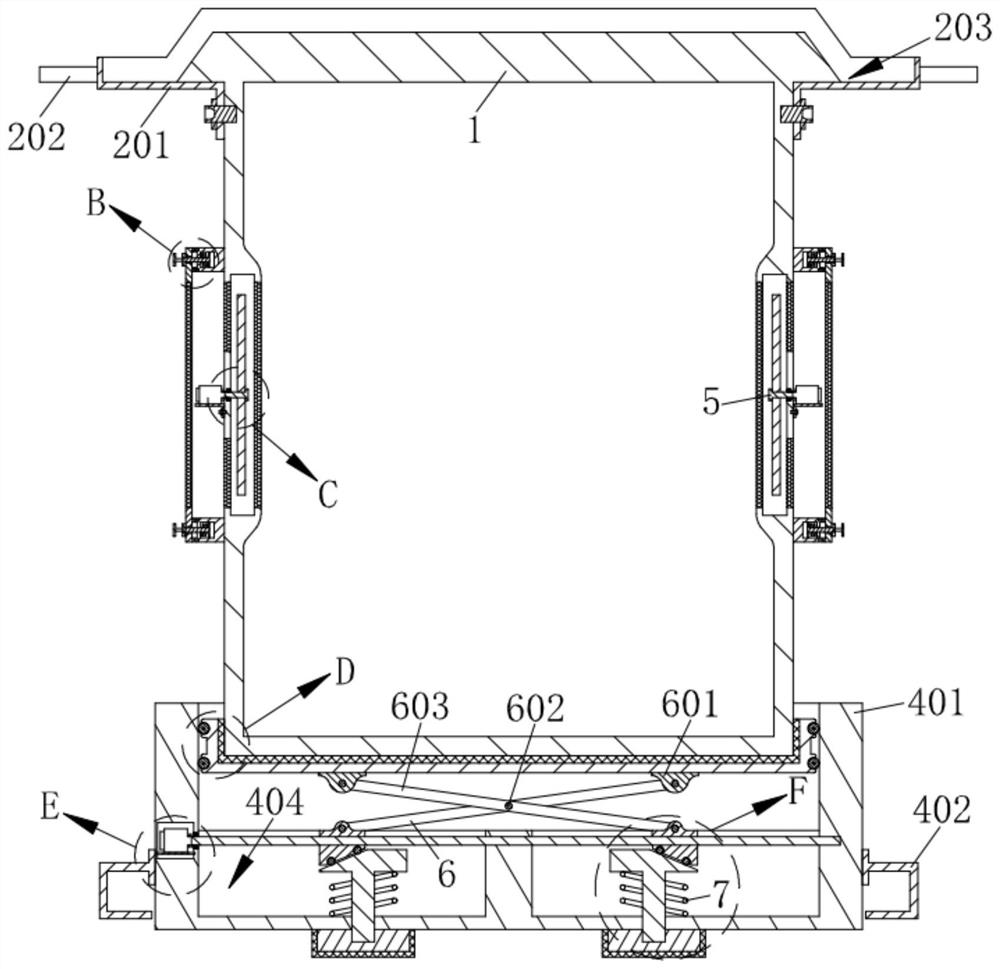

[0027] Such as Figure 1 - Figure 8 As shown, a power conveying cabinet of the present invention includes a cabinet 1, and a fixing mechanism 2 is mounted on the cabinet 1; the cabinet 1 is rotated with a heat dissipation mechanism 5; the cabinet The body 1 is fixed to a dust collecting mechanism 3; a support mechanism 4 is attached to the support mechanism 4; the support mechanism 4 is connected to the sliding mechanism 6 against the finite mechanism 7;

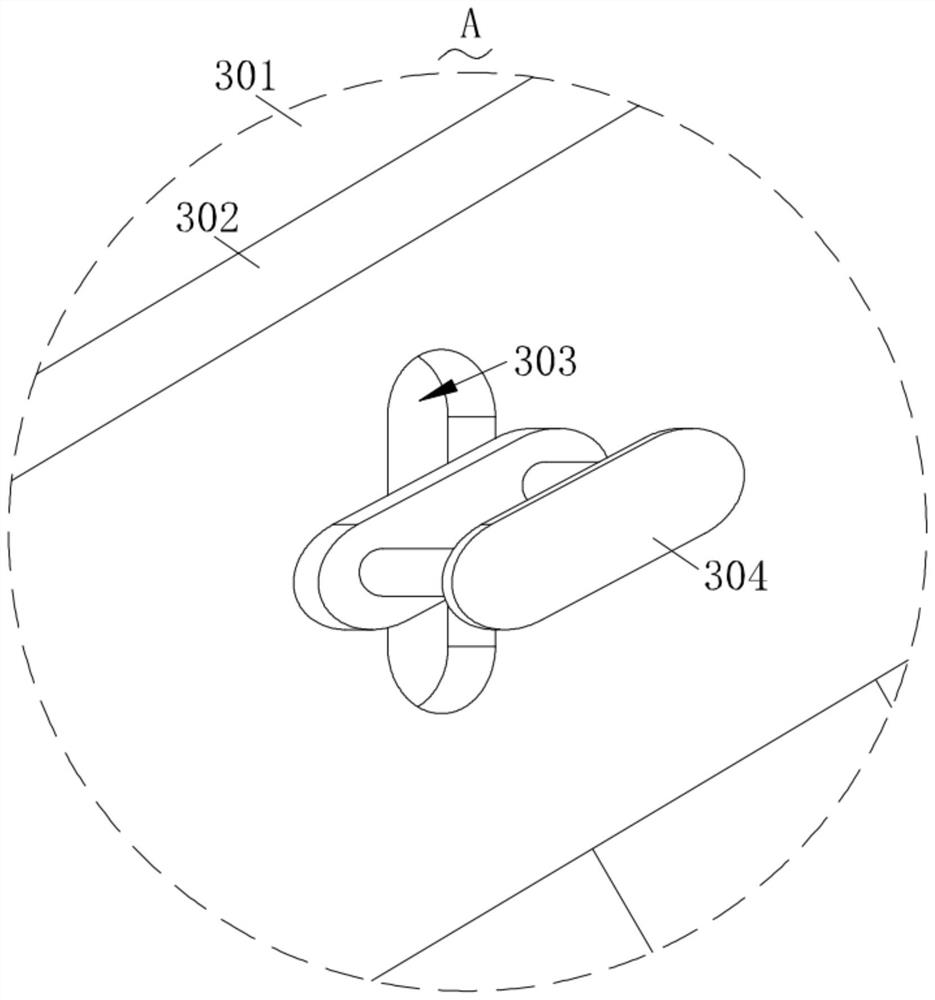

[0028] The dustproof mechanism 3 includes a fixing plate 301 that is fixed to the fixing plate 301, and the fastening plate 301 is engaged with a dustproof mesh 302, and a card slot is provided on the dust-proof mesh 302. 303. The card slot 303 is fitted with a slider 305, and the slider 305 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com