Anti-scorching rapid fixation equipment for green tea processing

A greening equipment and anti-scorch technology, which is applied in tea processing before extraction, conveyor objects, transportation and packaging, etc., can solve the problems of wasting time, low work efficiency, and difficulty in turning tea, so as to achieve uniform greening of tea leaves and reduce labor costs , stimulate the effect of fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

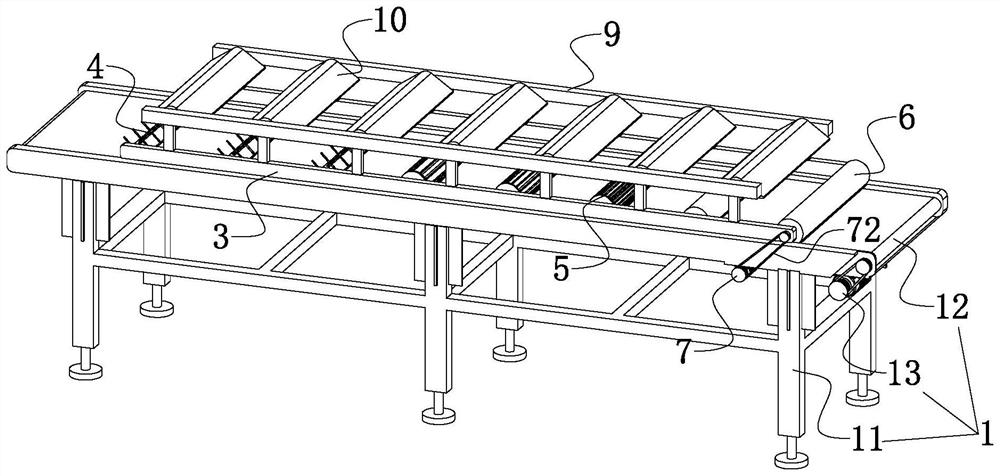

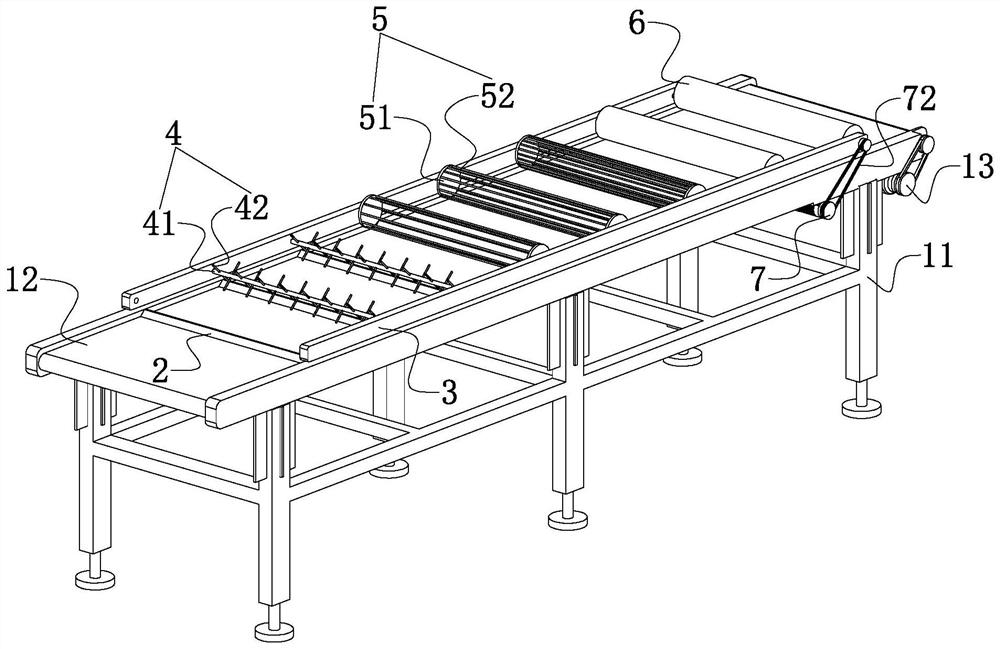

[0025] Examples, see Figure 1-3 , a green tea processing anti-scorch fast greening equipment, including a conveyor 1, the conveyor 1 includes a frame 11, a conveyor belt 12, a first drive motor 13 that drives the conveyor belt 12 to move, and the frame 11 is above the conveyor belt 12 Eight inclined scraping strips 2 inclined towards the same direction are horizontally arranged, and the lower end of each inclined scraping strip 2 is in contact with the conveyor belt 12, which is convenient for scraping the tea leaves moving with the conveyor belt 12 to turn the tea.

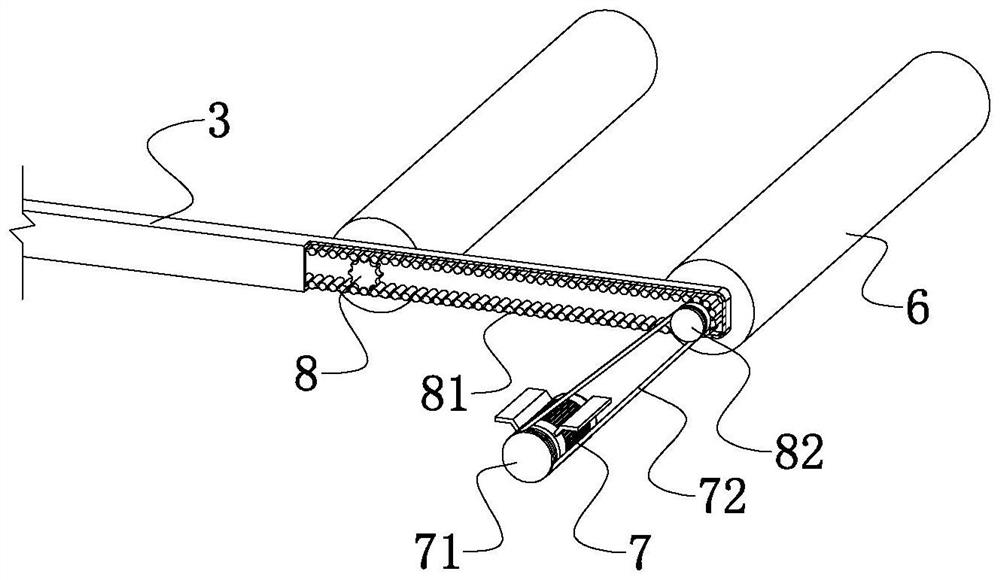

[0026] The upper ends on both sides of the frame 11 are provided with a strip-shaped installation shell 3, and eight rolling tea turners corresponding to the inclined scraping bars 2 are rotatably connected between the two strip-shaped installation shells 3. The lower end of each rolling tea tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com