Air heating smoking set capable of fully heating periphery of cigarette core section

A technology of air heating and hot air, which is applied in the field of tobacco, can solve the problems of affecting the feeling of smoking, wasting tobacco raw materials, and poor smoking experience, and achieve the effect of improving heating efficiency, increasing release rate, and good smoking experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a further understanding and understanding of the structural features and the achieved effects of the present invention, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

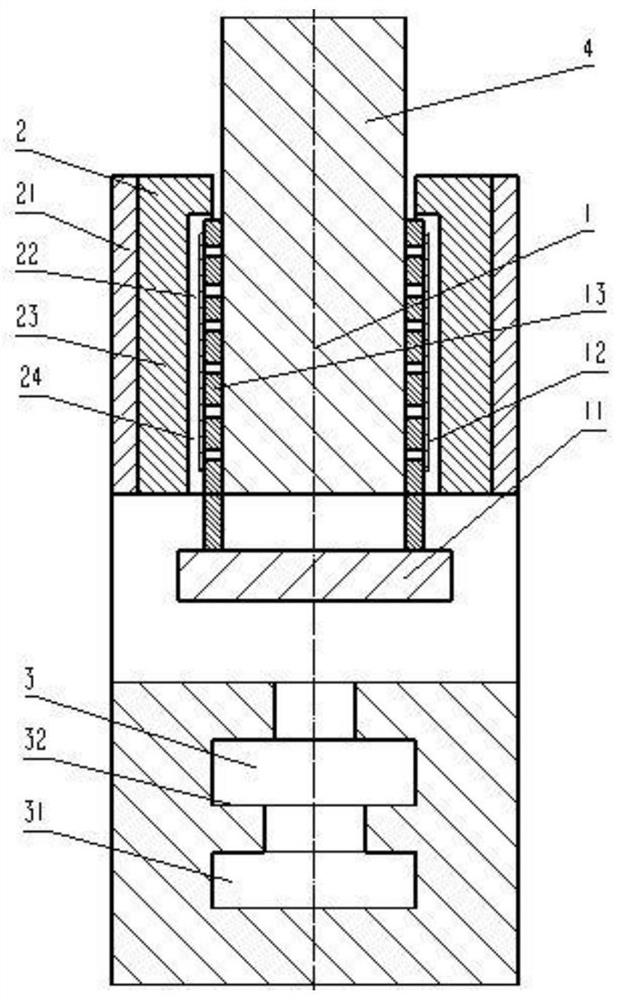

[0028] Such as figure 1 Shown is an air-heated smoking appliance with fully heated periphery of the cigarette core section, the smoking appliance includes: a hot air system 1, a tobacco material containing system 2 and a power control system 3;

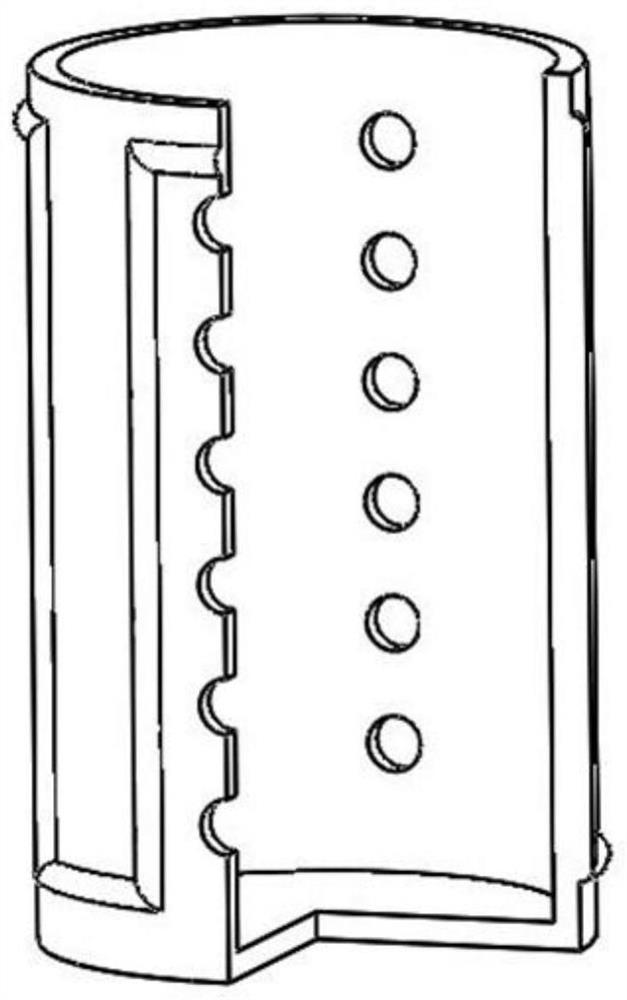

[0029] The hot air system 1 includes: an air chamber sleeve 13 and a heating element 12; figure 2 As shown, the air cavity sleeve 13 is cylindrical with holes on the side wall, and the porosity of the air cavity sleeve 13 is 50%; the heating element 12 is arranged on the inner wall of the air cavity sleeve 13 or on the outer wall; the heating element 12 is a thermal resistor; the length of the air cavity sleeve 13 is the same as the length of the tobacco core section of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com